Exploring Industrial Zigzag Sewing Machines for Enhanced Stitching Versatility and Efficiency

The Industrial Zigzag Sewing Machine A Versatile Tool in Textile Manufacturing

In the realm of textile manufacturing, the sewing machine has undergone significant transformations since its inception. Among the myriad types of sewing machines that have evolved, the industrial zigzag sewing machine stands out as a versatile and essential tool for various applications in the garment industry.

What is an Industrial Zigzag Sewing Machine?

An industrial zigzag sewing machine is designed to create stitch patterns that allow for both straight and zigzag stitches. Unlike traditional sewing machines that primarily produce straight stitches, the zigzag variant can handle a wider array of sewing tasks. This includes but is not limited to, securing fabrics, stitching elastic materials, and hemming edges. The machine is particularly favored for its ability to stretch fabrics without breaking the stitch, making it ideal for both woven and knit textiles.

Key Features

The industrial zigzag sewing machine is built for heavy-duty use. It typically operates at high speeds, capable of reaching up to 5,000 stitches per minute, which enhances productivity in a manufacturing setting. With a robust motor and a heavy frame, these machines are designed to withstand the rigors of continuous operation. Additionally, many models come equipped with adjustable stitch widths and lengths, offering operators the flexibility to customize their settings for different fabric types and project requirements.

Another notable feature is the presence of various presser feet attachments. These attachments allow for specialized tasks such as sewing hems, applying zippers, or crafting decorative stitches, making the machine a multifunctional asset in the workshop. The ability to change presser feet quickly is crucial in fast-paced production environments.

Applications in the Industry

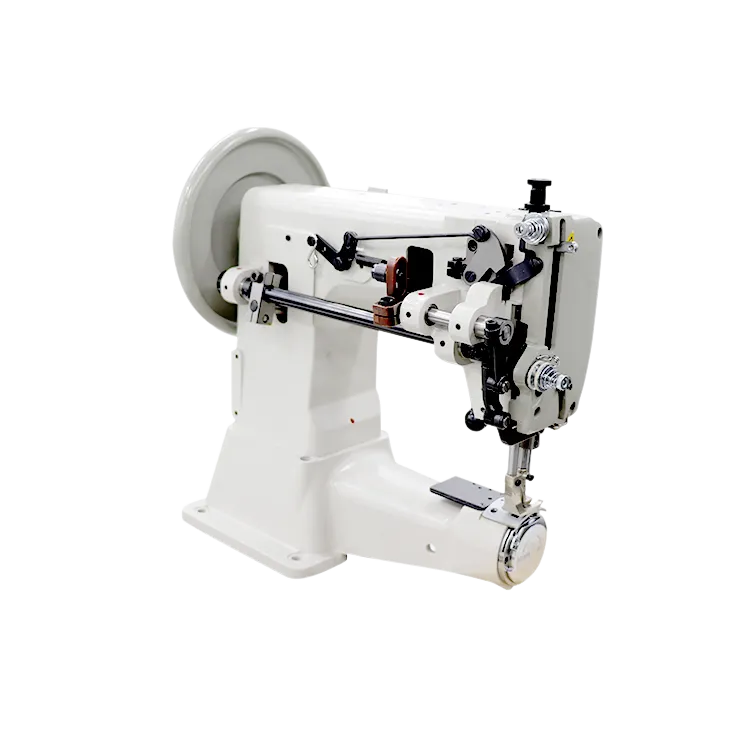

industrial zigzag sewing machine

The applications of the industrial zigzag sewing machine are vast. In the garment sector, it is a preferred choice for sewing clothing items like shirts, pants, and dresses. The zigzag stitch is particularly effective for sewing knit fabrics, as it provides the necessary elasticity without compromising the integrity of the seam. This is crucial in maintaining the garment's shape and comfort over time.

Furthermore, these machines are integral in creating decorative elements on garments. By adjusting the stitch settings, manufacturers can produce intricate patterns that enhance the aesthetic appeal of clothing products. Additionally, they are essential in upholstery work, where sturdy seams are vital for durability.

Advantages

One of the greatest advantages of the industrial zigzag sewing machine is its efficiency. With the ability to produce a variety of stitches quickly and accurately, manufacturers can streamline their production processes. This not only meets the demands of fast fashion but also minimizes labor costs and waste.

Moreover, the adaptability of the zigzag stitch allows for creative freedom. Designers and manufacturers can experiment with different fabrics and designs, pushing the boundaries of traditional sewing techniques. This versatility contributes to the innovative spirit in the textile industry.

Conclusion

In conclusion, the industrial zigzag sewing machine is an invaluable tool in modern textile manufacturing. Its robust construction, high-speed operation, and versatile applications make it a staple in garment production and beyond. As the industry continues to evolve, this machine will undoubtedly remain at the forefront, driving efficiency and creativity in fashion and textile design. The zigzag sewing machine not only enhances productivity but also empowers creators to explore new horizons in their craft, solidifying its place as a cornerstone of the manufacturing process.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025