Feb . 18, 2025 05:45

Back to list

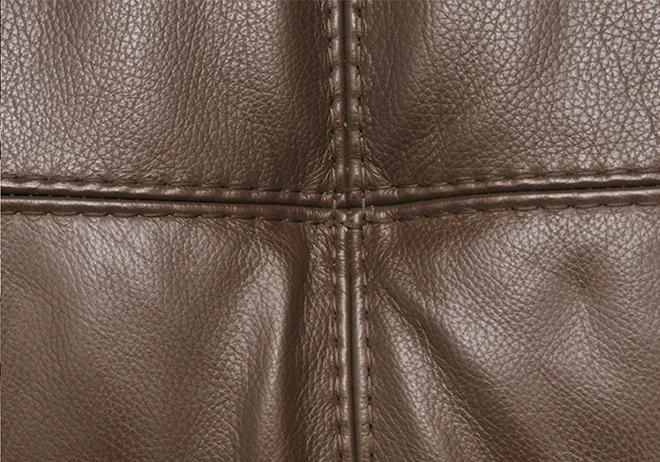

industrial zig zag machine

The world of industrial sewing is as intricate as the stitches it produces, with the industrial zig zag machine standing out as a cornerstone of modern textile manufacturing. These machines are pivotal for businesses aiming to enhance their production capabilities while maintaining top-tier quality.

An often overlooked aspect is the machine's contribution to sustainability. As the textile industry grapples with its environmental impact, choosing a zig zag machine that supports eco-friendly practices is vital. Machines that optimize thread use and minimize waste contribute to a more sustainable operation, aligning with modern ethical business practices. Those in the market for industrial zig zag machines should consider the practical experiences of seasoned professionals who repeatedly advocate for machines with advanced safety features. These machines are designed to protect users from accidents, incorporating features such as automatic shutoff and secure needle handling systems. Furthermore, in-depth reviews by specialists often emphasize the industrial zig zag machine’s role in innovation. By enabling the creation of complex patterns, these machines push the boundaries of what is traditionally possible in fabric design. This innovation allows manufacturers to offer unique, competitive products that stand out in the marketplace. In conclusion, the industrial zig zag machine is more than just a tool; it is an essential partner in delivering high-quality, reliable, and innovative textile products. Businesses that invest in these machines not only benefit from immediate enhancements in production efficiency and quality but also gain long-term advantages in sustainability and product differentiation. A strategic investment in a top-tier industrial zig zag machine is a testament to a company’s commitment to excellence and its vision for future growth.

An often overlooked aspect is the machine's contribution to sustainability. As the textile industry grapples with its environmental impact, choosing a zig zag machine that supports eco-friendly practices is vital. Machines that optimize thread use and minimize waste contribute to a more sustainable operation, aligning with modern ethical business practices. Those in the market for industrial zig zag machines should consider the practical experiences of seasoned professionals who repeatedly advocate for machines with advanced safety features. These machines are designed to protect users from accidents, incorporating features such as automatic shutoff and secure needle handling systems. Furthermore, in-depth reviews by specialists often emphasize the industrial zig zag machine’s role in innovation. By enabling the creation of complex patterns, these machines push the boundaries of what is traditionally possible in fabric design. This innovation allows manufacturers to offer unique, competitive products that stand out in the marketplace. In conclusion, the industrial zig zag machine is more than just a tool; it is an essential partner in delivering high-quality, reliable, and innovative textile products. Businesses that invest in these machines not only benefit from immediate enhancements in production efficiency and quality but also gain long-term advantages in sustainability and product differentiation. A strategic investment in a top-tier industrial zig zag machine is a testament to a company’s commitment to excellence and its vision for future growth.

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025