industrial zig zag machine

The Role of Industrial Zig Zag Machines in Modern Manufacturing

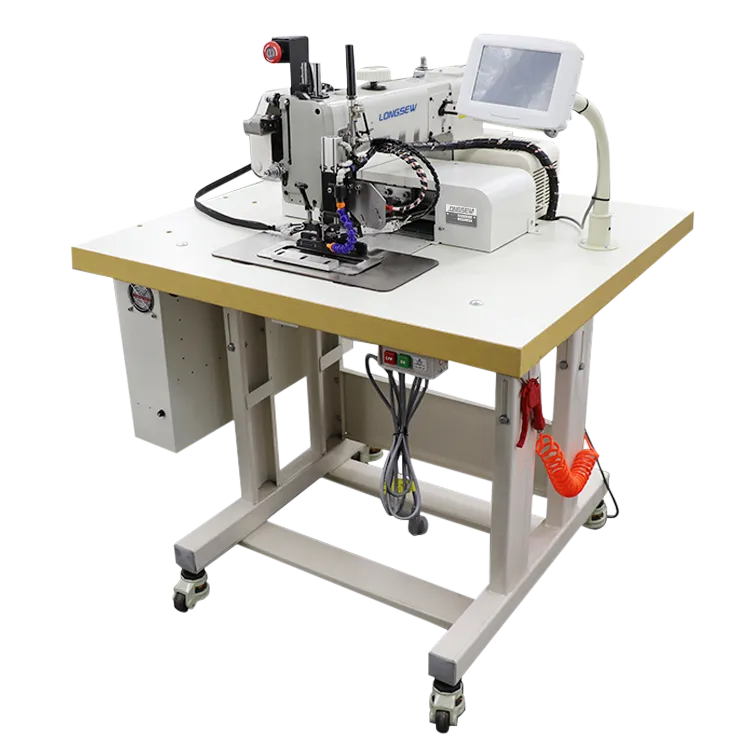

In today’s rapidly evolving manufacturing landscape, efficiency and versatility are paramount. As businesses strive to maximize productivity and reduce costs, specialized machinery has become indispensable. Among these machines, the industrial zig zag machine stands out as a critical tool in various sectors, including textiles, leather goods, and automotive manufacturing. This article explores the significance of the industrial zig zag machine, its operational mechanics, applications, and its impact on productivity.

Understanding Zig Zag Machines

The industrial zig zag machine is designed primarily for sewing applications where a zig zag stitch is needed. Unlike the straight stitch, the zig zag stitch provides greater flexibility and strength, making it ideal for joining two pieces of fabric, finishing edges, or creating decorative effects. These machines are equipped with advanced features that allow for adjustable stitch width and length, enabling manufacturers to customize their output according to specific requirements.

Operational Mechanics

The core mechanism of an industrial zig zag machine revolves around its needle and feed system. As the needle moves up and down, the machine shifts side to side, creating the characteristic zig zag pattern. This design not only enhances the strength of seams but also prevents fraying and unraveling, making it suitable for various fabric types, including stretchy and heavy materials.

Modern zig zag machines incorporate computerized technology, streamlining the sewing process. Digital displays allow operators to easily program stitch patterns and monitor machine performance in real-time. Additionally, these machines often feature automatic features such as thread cutting and needle positioning, which significantly reduce manual efforts and errors.

Applications Across Industries

1. Textiles In the textile industry, zig zag machines are widely used for stitching garments, especially when working with stretch fabrics like spandex or lycra. The flexibility of the zig zag stitch enables garments to retain shape and fit snugly, which is essential in athletic wear and fitted clothing.

industrial zig zag machine

2. Leather Goods The durability of the zig zag stitch makes it a preferred choice for sewing leather products. Whether crafting handbags, belts, or boots, the zig zag machine ensures that seams are not only aesthetically pleasing but also robust enough to withstand wear and tear.

3. Automotive In the automotive sector, the construction of interiors—such as seats and upholstery—often requires zig zag stitches. The machine's ability to handle thick and resilient materials is vital for producing high-quality automotive components that meet safety and durability standards.

4. Home Crafting With the rise of DIY culture, home sewing enthusiasts also benefit from industrial zig zag machines. Their versatility allows hobbyists to undertake a wide array of projects, from upholstery to garment making, enhancing creative capabilities.

Impacts on Productivity

The introduction of industrial zig zag machines has significantly transformed manufacturing processes. By combining speed with precision, these machines allow for faster production times, leading to increased output. The reduced need for manual finishing and adjustments further streamlines workflows, enabling manufacturers to allocate labor to other critical areas.

Moreover, the adaptability of zig zag machines means that manufacturers can easily switch between different textile types and stitch patterns, responding quickly to market demands. This flexibility is essential in a time when consumer preferences shift rapidly and custom orders are becoming more common.

Conclusion

In conclusion, the industrial zig zag machine plays a pivotal role in modern manufacturing. Its ability to produce strong, versatile stitches across various materials makes it an invaluable asset in industries ranging from textiles to automotive. As manufacturers continue to seek ways to enhance efficiency and adaptability, the zig zag machine’s advanced features and operational capabilities will likely continue to be at the forefront of industrial innovation, facilitating the production of high-quality goods tailored to ever-evolving consumer needs.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025