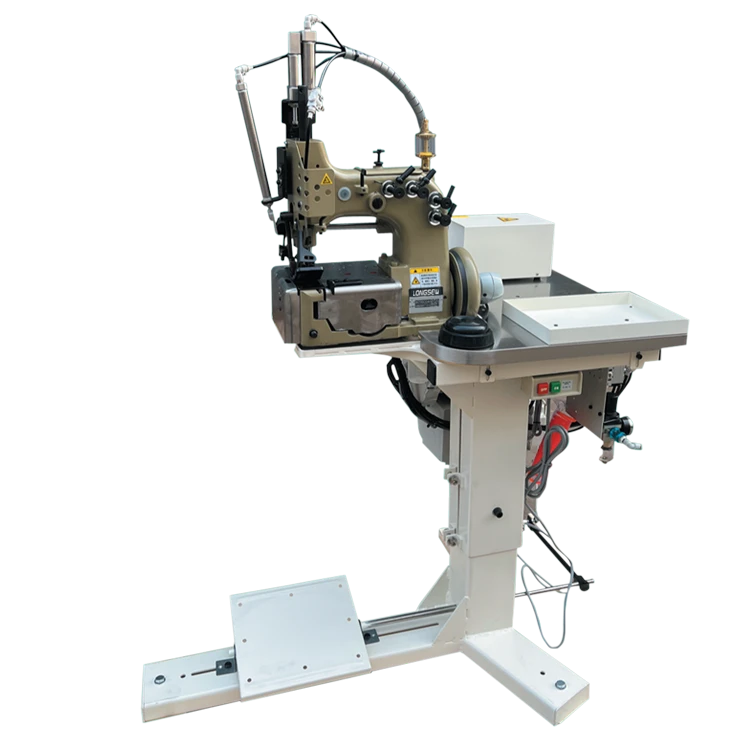

industrial upholstery machine

The Evolution and Importance of Industrial Upholstery Machines

The realm of upholstery has undergone significant transformations over the years, particularly with the innovations brought forth by advanced technology. Among the crucial advancements in this sector are industrial upholstery machines, designed specifically to meet the demands of large-scale production and intricate fabric work. These machines serve as the backbone of industries that deal with furniture, automotive, marine, and other applications where upholstery plays a vital role.

A Brief History of Upholstery Machines

Historically, upholstery was a labor-intensive process, relying heavily on manual skilled labor. Craftsmen used hand tools to cut, sew, and attach fabrics to furniture, vehicles, and other items. This process was not only time-consuming but also limited in production capacity. The introduction of sewing machines in the 19th century marked the beginning of a revolution in the upholstery industry, allowing for more consistent and rapid output. Over time, specialized machines were developed to handle various upholstery tasks, further streamlining the process.

Features of Industrial Upholstery Machines

Today’s industrial upholstery machines are marvels of engineering, featuring advanced technology that enhances efficiency, precision, and ease of use. Here are some critical features that distinguish industrial upholstery machines from their domestic counterparts

1. Heavy-Duty Construction Industrial upholstery machines are built to withstand the rigorous demands of heavy fabric and continuous use. They are typically made from robust materials that ensure longevity and reliability.

2. High-Speed Operation These machines are engineered for high-speed sewing, significantly reducing the time it takes to complete upholstery tasks. This feature is particularly beneficial for factories that require large volumes of output.

3. Automatic Functions Many modern industrial machines come equipped with automatic functions such as thread trimming, bobbin winding, and even fabric feeding. These automated features not only enhance productivity but also minimize the likelihood of human error.

industrial upholstery machine

4. Specialized Attachments Industrial upholstery machines can accommodate a variety of attachments and accessories, allowing them to perform multiple operations, such as stitching, tufting, and even applying adhesive. This versatility makes them suitable for various upholstery applications, from sofas and chairs to car interiors.

5. Advanced Technology Integration With the advent of computerized sewing systems, many industrial upholstery machines feature programmable settings that can be tailored to specific tasks. This technology allows for precise stitching patterns and consistent quality across large production runs.

Applications in Various Industries

The application of industrial upholstery machines spans various sectors, each with its unique requirements. In the furniture industry, these machines are indispensable for producing upholstered items such as sofas, chairs, and mattresses. They ensure that the fabric fits perfectly and is securely attached, leading to durable and aesthetically pleasing products.

In the automotive sector, upholstery machines play a crucial role in creating comfortable and stylish interiors. Car manufacturers rely on these machines to upholster seats, doors, and dashboards with precision and speed. The ability to work with different types of materials, including leather, vinyl, and fabric, is essential for meeting the diverse needs of this industry.

The marine industry also benefits from industrial upholstery machines, which are used to create durable and weather-resistant coverings for boats and yachts. These machines help produce items like seat cushions, bimini tops, and various other marine accessories designed to withstand harsh environmental conditions.

The Future of Upholstery Machines

As technology continues to advance, the future of industrial upholstery machines looks promising. Innovations such as artificial intelligence and robotics are expected to further enhance efficiency and precision in upholstery work. Moreover, the growing focus on sustainability may lead to the development of machines that work with eco-friendly materials and processes.

In conclusion, industrial upholstery machines are essential tools that have transformed the upholstery industry. They provide the speed, precision, and versatility needed to meet the demands of modern production while ensuring high-quality results. As technology evolves, these machines will undoubtedly continue to play a pivotal role in shaping the future of upholstery across various industries. Whether in furniture, automotive, or marine applications, the impact of industrial upholstery machines is profound and far-reaching, marking a significant chapter in the evolution of this craft.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025