industrial single needle lock stitch sewing machine with needle guard

Industrial Single Needle Lock Stitch Sewing Machine with Needle Guard

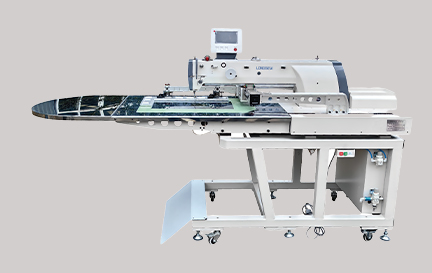

In the realm of textile manufacturing, the significance of sewing machines cannot be overstated. Among the myriad designs available, the industrial single needle lock stitch sewing machine stands out as a fundamental tool for high-volume production. With the integration of features such as a needle guard, this machine not only enhances efficiency but also prioritizes safety, making it a highly sought-after option in garment factories and tailoring shops around the world.

Understanding the Single Needle Lock Stitch Sewing Machine

The single needle lock stitch sewing machine operates by using two threads the upper thread, which is fed through the needle, and the lower thread, which is wound on a bobbin located beneath the sewing plate. This mechanism creates a strong and durable stitch that is ideal for a variety of fabrics, from lightweight silks to heavy-duty materials like denim. The versatility of this machine makes it suitable for different applications, including garment construction, upholstery, and various textile crafts.

One of the key advantages of the single needle lock stitch machine is its simplicity and robustness. It features a straightforward design that allows for easy operation, which is essential in high-paced manufacturing environments where time is money. Additionally, the single needle setup minimizes the likelihood of thread bunching or tangling, ensuring a smooth sewing experience.

The Role of the Needle Guard

Integrating a needle guard into the design of the sewing machine is a significant enhancement that focuses on operator safety

. The needle guard is a protective device that surrounds the needle area, reducing the risk of accidental needle punctures, which can lead to injury. In busy industrial settings, where operators are often handling multiple tasks simultaneously, the needle guard serves as a crucial safety feature, allowing workers to focus on their responsibilities without constantly worrying about potential injuries.Moreover, the needle guard can also help maintain the positioning of the fabric during sewing. By providing a tactile boundary, it aids in guiding the fabric correctly, which can be particularly beneficial when dealing with intricate patterns or layered materials. This feature not only improves the quality of the finished product but also boosts the confidence of the operator.

industrial single needle lock stitch sewing machine with needle guard

Efficiency and Productivity

The industrial single needle lock stitch machine is designed for speed and efficiency. With a high sewing speed, often exceeding 5,000 stitches per minute, this machine facilitates rapid completion of sewing projects, allowing factories to meet tight deadlines and increasing overall productivity. The needle guard does not impede this speed; instead, it enhances the operator's ability to work swiftly while ensuring safety and accuracy.

Furthermore, the machine's adjustable settings enable operators to tailor stitch tension and length according to the fabric used. This adaptability is essential for achieving the desired finish on different types of textiles. As a result, manufacturers can produce a wide range of products, from basic garments to more complex pieces that require precision.

Maintenance and Longevity

Maintaining the industrial single needle lock stitch sewing machine is crucial for ensuring its longevity and optimal performance. Routine maintenance involves regular cleaning, lubrication, and timely replacement of worn-out parts. With the integration of a needle guard, some maintenance tasks become more straightforward, as it protects sensitive components from dust and debris, thereby extending the life of the machine.

Conclusion

The industrial single needle lock stitch sewing machine equipped with a needle guard is an indispensable asset for any garment manufacturing operation. By combining safety, efficiency, and versatility, it addresses the needs of modern textile production while fostering a safer working environment for operators. As the industry continues to evolve, machines like these will remain at the forefront, driving innovation and productivity in sewing technology. Investing in such equipment is not just a choice for quality production; it is a commitment to the safety and well-being of the workforce that powers the textile industry.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025