Jan . 16, 2025 02:40

Back to list

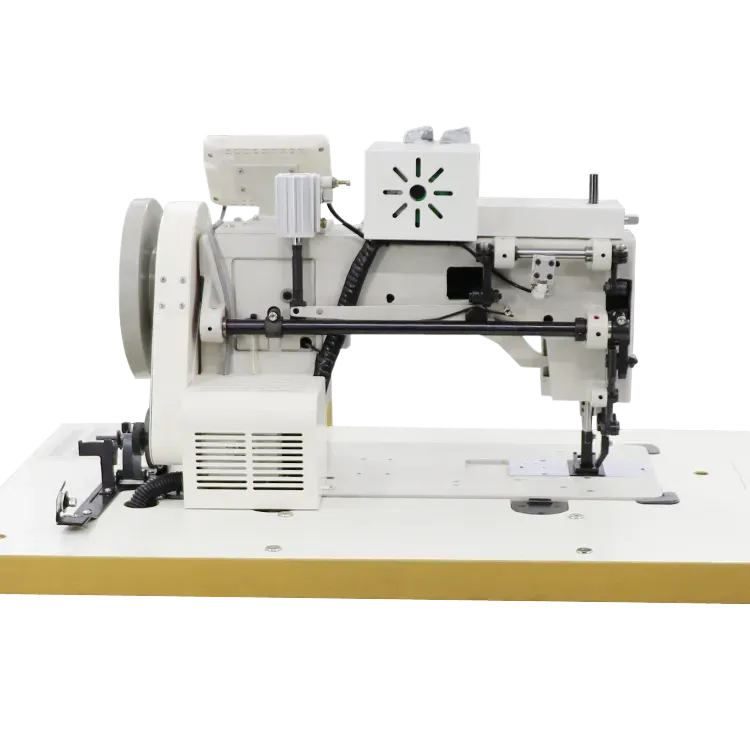

industrial single needle lock stitch sewing machine

In the ever-evolving landscape of industrial sewing, the single needle lock stitch sewing machine with a needle guard has emerged as an indispensable tool for manufacturers striving for efficiency and precision. A well-engineered piece of machinery, it has transformed the way industrial sewing is approached, marrying technology with craftsmanship in a seamless dance of productivity and innovation.

Expertise in this domain is not just about understanding the mechanical components but also about appreciating the nuanced adjustments that can be made to cater to different fabrics and productions. Advanced models come equipped with programmable functions, enabling experienced operators to take creative liberties in stitch design, all the while ensuring that each stitch remains functionally robust. This flexibility has broadened the scope for customization in industrial sewing, supporting diverse applications from automotive upholstery to specialized fashion sectors. Authoritativeness in industrial sewing is achieved through knowledge sharing and innovation. The leading manufacturers of these machines have established their authority not just by producing superior machinery, but by investing in research and development. Their collaboration with industry experts has led to continuous improvements in machine design and capabilities. This ensures that each machine is a testament to cutting-edge technology, backed by extensive field testing and endorsements from large-scale production floors across the globe. Trustworthiness is cemented through consistency and reliability. The longevity of a single needle lock stitch sewing machine with a needle guard is a critical factor in its selection by manufacturers. A machine that operates efficiently under rigorous conditions with minimal maintenance down-time commands trust. This is compounded by the manufacturer's support network, availability of spare parts, service assistance, and warranty guarantees, all of which contribute towards a seamless, trustworthy experience for the user. In conclusion, the industrial single needle lock stitch sewing machine with a needle guard delivers a confluence of precision, safety, and efficiency, making it an essential apparatus in the modern sewing industry. Its versatility and reliability underpin its role in enhancing manufacturing capabilities, empowering operators with the tools to produce superior quality while ensuring operator safety. As technology continues to advance, these machines stand as a testament to the symbiotic relationship between innovation and traditional craftsmanship, setting the standard for future developments in the field of industrial sewing.

Expertise in this domain is not just about understanding the mechanical components but also about appreciating the nuanced adjustments that can be made to cater to different fabrics and productions. Advanced models come equipped with programmable functions, enabling experienced operators to take creative liberties in stitch design, all the while ensuring that each stitch remains functionally robust. This flexibility has broadened the scope for customization in industrial sewing, supporting diverse applications from automotive upholstery to specialized fashion sectors. Authoritativeness in industrial sewing is achieved through knowledge sharing and innovation. The leading manufacturers of these machines have established their authority not just by producing superior machinery, but by investing in research and development. Their collaboration with industry experts has led to continuous improvements in machine design and capabilities. This ensures that each machine is a testament to cutting-edge technology, backed by extensive field testing and endorsements from large-scale production floors across the globe. Trustworthiness is cemented through consistency and reliability. The longevity of a single needle lock stitch sewing machine with a needle guard is a critical factor in its selection by manufacturers. A machine that operates efficiently under rigorous conditions with minimal maintenance down-time commands trust. This is compounded by the manufacturer's support network, availability of spare parts, service assistance, and warranty guarantees, all of which contribute towards a seamless, trustworthy experience for the user. In conclusion, the industrial single needle lock stitch sewing machine with a needle guard delivers a confluence of precision, safety, and efficiency, making it an essential apparatus in the modern sewing industry. Its versatility and reliability underpin its role in enhancing manufacturing capabilities, empowering operators with the tools to produce superior quality while ensuring operator safety. As technology continues to advance, these machines stand as a testament to the symbiotic relationship between innovation and traditional craftsmanship, setting the standard for future developments in the field of industrial sewing.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025