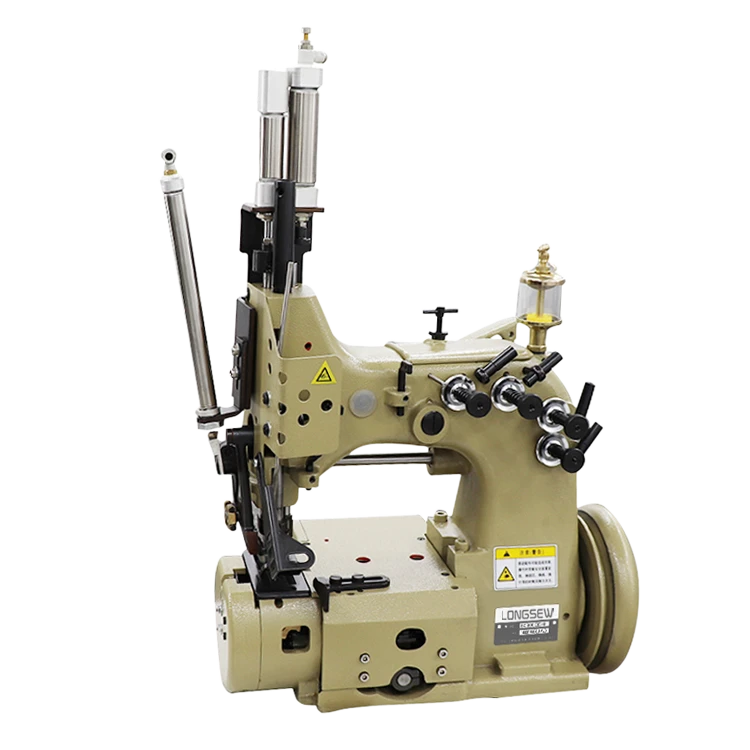

High-Performance Single Needle Industrial Lock Stitch Sewing Machine for Versatile Apparel Production

The Industrial Single Needle Lock Stitch Sewing Machine A Cornerstone of Modern Apparel Production

In the world of textile manufacturing, few machines have had as profound an impact as the industrial single needle lock stitch sewing machine. This versatile piece of equipment serves as a backbone for garment production, providing efficiency, precision, and reliability. Understanding its mechanics, advantages, and applications is crucial for anyone involved in the apparel industry.

What is a Single Needle Lock Stitch Sewing Machine?

The single needle lock stitch sewing machine operates on a simple principle it interlocks a single needle thread with a bobbin thread, creating a tight, durable stitch. This type of stitching is known for its strength and consistency, making it ideal for various fabrics, from lightweight cotton to heavier materials like denim. The machine features a straightforward design, typically composed of a needle, a bobbin case, and a feed mechanism, which facilitates the smooth movement of fabric during the sewing process.

Key Features and Functionality

One of the primary attributes of the industrial single needle lock stitch sewing machine is its speed. Many models can sew at speeds exceeding 5,000 stitches per minute, significantly reducing production time. Additionally, these machines often come equipped with features such as automatic thread trimming, adjustable presser foot pressure, and variable stitch lengths, allowing users to customize settings according to their specific needs.

Moreover, the lock stitch mechanism ensures that the stitches are securely locked in place, preventing unraveling over time. This reliability is essential in the apparel industry, where the quality of stitching can be a deciding factor in a garment's performance and longevity.

Advantages of Using Industrial Single Needle Lock Stitch Machines

1. Precision and Consistency Single needle lock stitch machines create uniform stitches, which are critical for meeting industry standards and customer expectations. This precision is especially important for high-quality garments that require exact measurements and finishes.

2. Versatility These machines can sew a wide variety of fabrics, making them suitable for numerous applications in the apparel sector, including making shirts, trousers, dresses, and more. Their adaptability allows manufacturers to streamline production processes.

industrial single needle lock stitch sewing machine

3. Cost-Effectiveness While the initial investment in industrial sewing machines may be significant, their durability and efficiency lead to reduced operational costs over time. Manufacturers benefit from lower labor costs due to the machines' high productivity.

4. Ease of Use Modern industrial single needle lock stitch machines are designed with user-friendly controls and ergonomic features, making them easy to operate for both experienced and novice sewists. This accessibility ensures that training costs are minimized.

Applications Across Industries

The industrial single needle lock stitch sewing machine finds utility not only in garment production but also in various sectors, including home textiles, automotive upholstery, and industrial fabrics. In the fashion industry, these machines are crucial for creating everything from casual wear to sophisticated evening gowns. In home textiles, they are used to produce curtains, bed linens, and upholstery. Additionally, in automotive applications, they play a role in crafting seat covers and interior fabrics.

Future Trends

As technology continues to evolve, so do the capabilities of industrial single needle lock stitch sewing machines. Innovations such as computerized controls, integrated sensors, and the ability to connect to design software are transforming the sewing landscape. These advancements enhance precision and enable real-time monitoring of production, reducing waste and improving overall efficiency.

Furthermore, sustainability is becoming a key consideration in the textile industry. As manufacturers seek environmentally friendly practices, the development of energy-efficient sewing machines and the use of sustainable materials is becoming increasingly important.

Conclusion

The industrial single needle lock stitch sewing machine remains a fundamental tool in the apparel industry, thanks to its reliability, speed, and versatility. Whether in a bustling factory or a small workshop, this machine plays an essential role in bringing designs to life. As technology progresses and industry demands evolve, these machines will continue to adapt, ensuring they remain at the forefront of textile manufacturing for years to come. Whether you are a manufacturer, designer, or hobbyist, understanding the capabilities of this essential equipment is key to achieving success in the textile world.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025