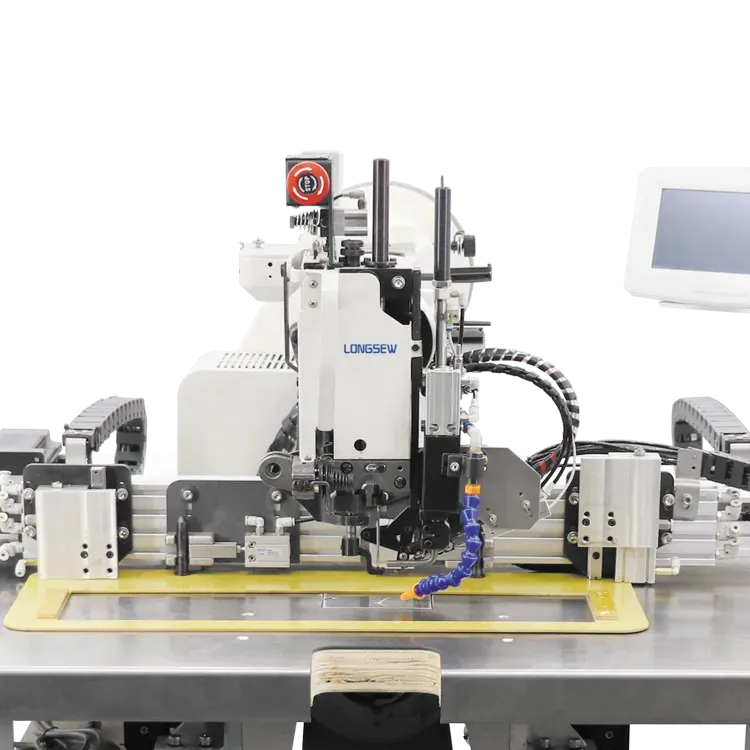

Heavy-Duty Single Needle Lock Stitch Sewing Machine for Industrial Use

The Industrial Single Needle Lock Stitch Machine A Crucial Tool for Textile Manufacturing

In the contemporary textile industry, the demand for precision, efficiency, and durability in sewing machinery is paramount. Among the various types of sewing machines prevalent in factories and workshops, the industrial single needle lock stitch machine stands out as a vital tool. This machine is not only a workhorse in garment production but also a symbol of innovation and advancement in textile technology.

Overview of the Single Needle Lock Stitch Machine

As the name suggests, the single needle lock stitch machine operates using a single needle to create a lock stitch, which is one of the most common stitches used in the apparel industry. The operation of this machine involves two threads an upper thread, supplied from a spool, and a lower thread, which is typically a bobbin thread that is housed in the machine. These threads intertwine to create a durable and secure stitch.

The simplicity of the single needle lock stitch machine is among its greatest advantages. It is relatively easy to operate and maintain, making it accessible for manufacturers of all scales. This machine is designed primarily for sewing woven and knit fabrics, often utilized for seams in shirts, pants, and coats where strength is critical.

Key Features and Benefits

1. Versatility The single needle lock stitch machine can handle a wide variety of fabrics, ranging from lightweight cotton to heavier materials like denim and canvas. This versatility makes it an invaluable asset in a diverse range of garment production.

2. High Stitch Quality The lock stitch produced by this machine is known for its neatness and precision. This feature is essential for ensuring high-quality finished products that meet consumer expectations, leading to increased customer satisfaction and brand loyalty.

industrial single needle lock stitch machine

3. Speed and Efficiency Industrial variations of single needle lock stitch machines can sew at impressive speeds, reaching 5,000 stitches per minute or more. This efficiency significantly boosts productivity in a manufacturing environment and reduces turnaround times for finished goods.

4. Robust Construction These machines are built to endure the rigors of continuous operational use. With sturdy metal frames and durable internal components, industrial single needle lock stitch machines are designed for longevity, thus providing a good return on investment for manufacturers.

5. Ease of Use With intuitive controls and straightforward threading processes, operators can quickly become proficient in using the machine. Furthermore, many models come equipped with features like automatic needle positioning and thread trimming, enhancing usability.

Challenges and Solutions

Despite the numerous benefits, the industrial single needle lock stitch machine is not without its challenges. Common issues include thread breakage, tension problems, and needle damage. To mitigate these problems, operators must be well-trained in machine maintenance and troubleshooting. Manufacturers often provide extensive training sessions and support resources to ensure optimal machine performance.

Additionally, the advent of technology has introduced computerized models that integrate advanced features such as stitch pattern programming, automatic tension adjustments, and enhanced monitoring systems. These innovations help alleviate some of the traditional challenges associated with the operation of single needle lock stitch machines.

Conclusion

The industrial single needle lock stitch machine remains an indispensable tool in the textile industry, celebrated for its precision, efficiency, and versatility. As the demand for high-quality garments continues to grow, the importance of reliable sewing technology cannot be overstated. With ongoing advancements in design and functionality, the evolution of single needle lock stitch machines will continue to shape the landscape of garment manufacturing, enabling businesses to meet consumer demands while maintaining optimal production efficiency. Investing in these machines not only enhances product quality but also positions companies to thrive in an increasingly competitive market.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025