Straight Stitch and Zig Zag Industrial Sewing Machines for Versatile Fabric Manipulation

Industrial Sewing Machines Straight Stitch and Zigzag Functionality

In the realm of textile manufacturing, industrial sewing machines play a crucial role in enhancing productivity, efficiency, and precision. Among the various types of sewing machines utilized in industry, the straight stitch and zigzag sewing machines are two of the most essential and widely used. Each type serves distinct purposes, contributing significantly to the quality and versatility of sewn products.

Straight Stitch Sewing Machines

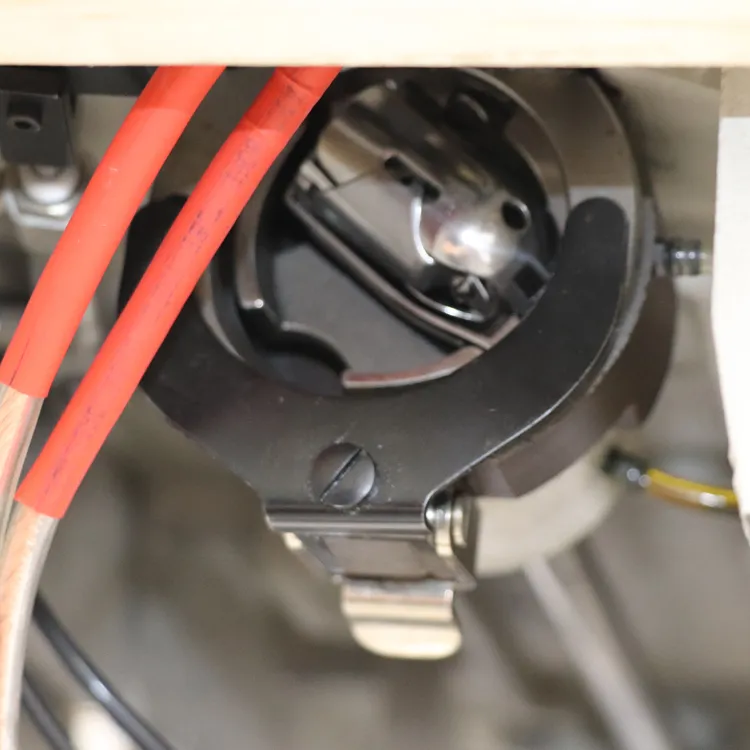

The straight stitch sewing machine is a staple in the textile Industry. It is widely recognized for its ability to create robust, straight seams that are vital for various applications. This type of machine typically features a single needle and operates using a straightforward mechanism that produces a lockstitch. The lockstitch is formed when the needle-thread passes through the fabric and interlocks with the bobbin thread below. This mechanism results in strong, durable seams, making straight stitch machines ideal for sewing garments, upholstery, and other fabric constructions.

One of the significant advantages of straight stitch machines is their speed. High-speed variants can outperform manual machines, sewing hundreds of stitches per minute, thus meeting the demands of mass production. They are also equipped with adjustable stitch lengths, which enables tailors and manufacturers to adapt to different fabric types and project requirements. Moreover, with computerized versions available, operators can program intricate patterns and stitch types with ease, increasing versatility.

However, while straight stitch sewing machines excel at creating strong seams, they are somewhat limited in their scope of functions. They typically cannot perform decorative stitching. Therefore, they are often complemented by other types of machines that can provide the variety needed in garment construction.

Zigzag Sewing Machines

Zigzag sewing machines, on the other hand, introduce a wider range of functionalities. These machines can create zigzag stitches in addition to straight stitches, providing the ability to sew elastic materials, finish edges, and create decorative patterns. The zigzag stitch is formed when the needle moves side to side as well as up and down, allowing the fabric to be sewn together while also allowing for stretch.

industrial sewing machine straight stitch and zig zag

The versatility of zigzag machines makes them invaluable in various applications, particularly in garment construction and alteration. They are excellent for sewing knit fabrics and providing a clean finish on seams, helping to prevent fraying. The use of zigzag stitches is especially prevalent in stretchable fabrics, such as sportswear and swimwear, where the ability to stretch is critical. Additionally, these machines allow for multiple widths and lengths of zigzag stitches, enabling designers to create unique embellishments and decorative effects.

For advanced sewing projects, zigzag sewing machines may also come with additional features such as multiple stitch patterns, automatic thread tensioning, and automatic needle threading. These enhancements not only streamline workflow but also reduce the likelihood of errors, contributing to higher quality in finished products.

Choosing Between Straight Stitch and Zigzag Machines

When deciding between straight stitch and zigzag sewing machines, several factors must be considered. The choice largely depends on the specific needs of the sewing project or business.

For projects that necessitate high speed and strong seams, such as traditional garment production, a dedicated straight stitch sewing machine might be the ideal choice. In contrast, if a project requires versatility in stitch types, especially when working with stretch fabrics or where decorative stitching is involved, a zigzag sewing machine would be more suitable. Often, manufacturers will need to invest in both types of machines to ensure they can cater to a wide variety of textile applications and client demands.

Conclusion

In conclusion, both straight stitch and zigzag industrial sewing machines are integral to the textile industry. Their unique functionalities not only enhance efficiency and accuracy in production but also expand the creative possibilities of garment design. As technology advances, the capabilities of these machines will continue to evolve, further revolutionizing the textile manufacturing landscape. Whether creating sturdy seams or intricate decorative designs, the importance of these sewing machines will remain paramount in the world of industrial textiles.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025