Feb . 19, 2025 01:53

Back to list

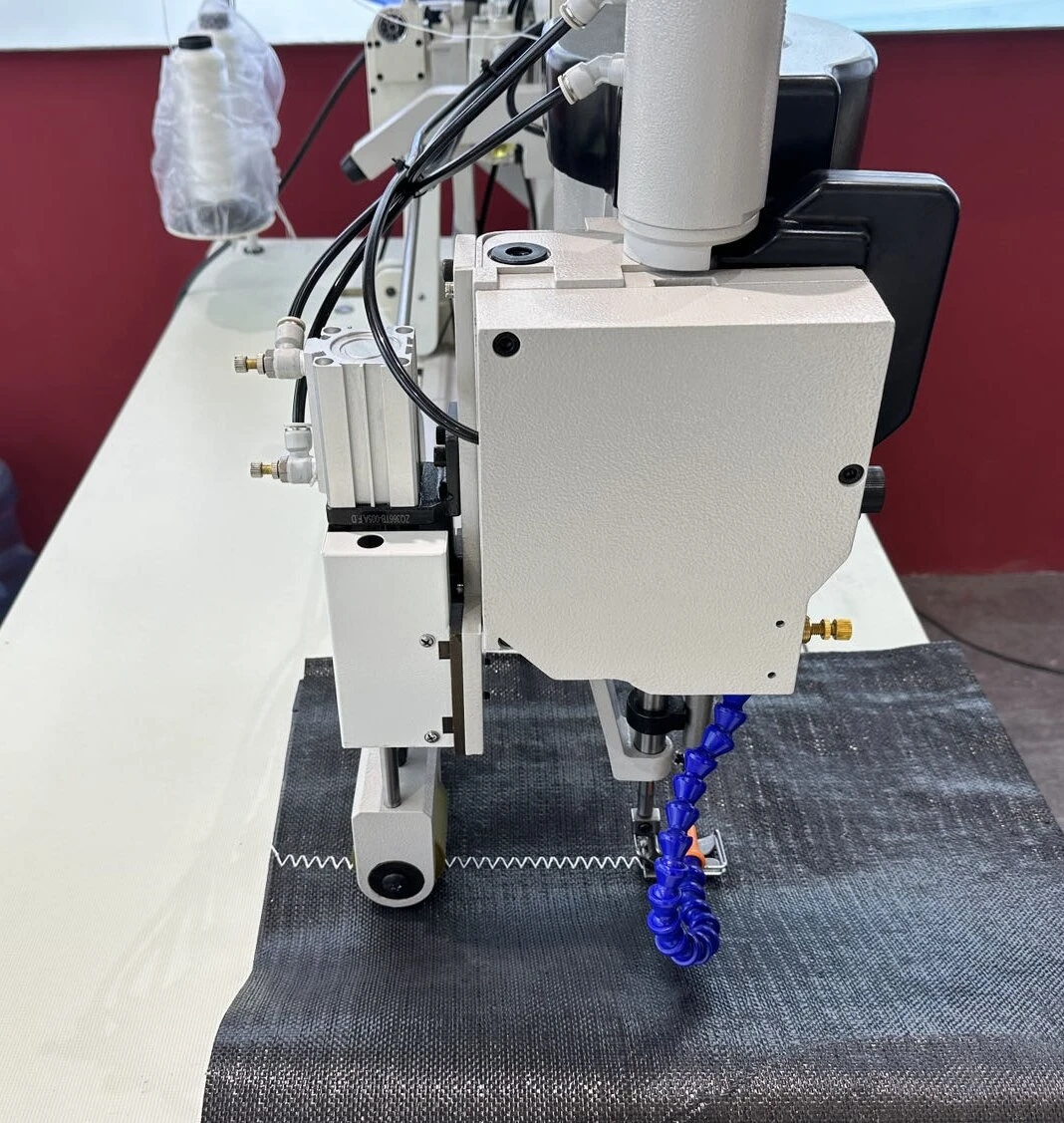

industrial sewing machine straight stitch and zig zag

In the world of garment production and textile design, the industrial sewing machine stands as a crucial tool, particularly those that offer both straight stitch and zigzag capabilities. These machines cater to a range of applications, from creating durable seams on heavy fabrics to crafting delicate designs on lighter materials. For professionals who demand precision, speed, and reliability, understanding the dual functionalities of straight stitch and zigzag stitch machines is vital.

Investing in a high-quality industrial sewing machine with both straight and zigzag stitch capabilities is a decision that leverages long-term efficiency and cost-effectiveness. The initial outlay on a superior machine is quickly balanced by the reduction in maintenance costs and increased throughput. Furthermore, the reliability of these machines ensures minimal disruption, allowing for consistent production schedules and timely project completion. For those who operate within competitive industries, demonstrating expertise in utilizing versatile industrial sewing machinery can greatly enhance credibility and authority. Training and continued education on these machines can distinguish skilled professionals, positioning them as leaders in a crowded market. This expertise not only increases operational proficiency but also builds trust with clients seeking high-quality workmanship. Trustworthiness stems from not only possessing the right tools but also knowing how to deploy them effectively. By mastering the nuances of sewing machine operation and maintenance, professionals can guarantee their clients a superior product both in function and form. An adept understanding of stitch selection, machine calibration, and fabric interaction underscores a commitment to excellence — a trait that is invaluable in securing client loyalty and building a reputable portfolio. In conclusion, the decision to harness the dual functions of straight stitch and zigzag stitch in an industrial sewing machine is both a strategic and operational advantage. By doing so, professionals can craft well-constructed garments that meet both practical and aesthetic standards, ensuring their place at the forefront of the textile industry.

Investing in a high-quality industrial sewing machine with both straight and zigzag stitch capabilities is a decision that leverages long-term efficiency and cost-effectiveness. The initial outlay on a superior machine is quickly balanced by the reduction in maintenance costs and increased throughput. Furthermore, the reliability of these machines ensures minimal disruption, allowing for consistent production schedules and timely project completion. For those who operate within competitive industries, demonstrating expertise in utilizing versatile industrial sewing machinery can greatly enhance credibility and authority. Training and continued education on these machines can distinguish skilled professionals, positioning them as leaders in a crowded market. This expertise not only increases operational proficiency but also builds trust with clients seeking high-quality workmanship. Trustworthiness stems from not only possessing the right tools but also knowing how to deploy them effectively. By mastering the nuances of sewing machine operation and maintenance, professionals can guarantee their clients a superior product both in function and form. An adept understanding of stitch selection, machine calibration, and fabric interaction underscores a commitment to excellence — a trait that is invaluable in securing client loyalty and building a reputable portfolio. In conclusion, the decision to harness the dual functions of straight stitch and zigzag stitch in an industrial sewing machine is both a strategic and operational advantage. By doing so, professionals can craft well-constructed garments that meet both practical and aesthetic standards, ensuring their place at the forefront of the textile industry.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025