Industrial Sewing Needles Suitable for Leather Crafting and Manufacturing Processes

The Importance of Industrial Sewing Machine Needles for Leather Work

When it comes to industrial sewing, particularly in the leatherworking sector, the choice of sewing machine needles can significantly influence the outcome of the final product. Leather, being a tough and durable material, requires specialized needles to ensure efficient stitching and to achieve the desired finish. Understanding the various types of industrial sewing machine needles designed for leather is essential for achieving high-quality results in leather crafting.

Types of Industrial Sewing Machine Needles for Leather

Industrial sewing machine needles are categorized based on their size, type, and design. For leatherwork, the most commonly used needles are the wedge or leather needles. Unlike regular sewing needles, leather needles feature a triangular point that pierces the leather fibers rather than pushing them aside. This reduces the risk of damaging the material and ensures that the stitches hold securely.

1. Wedge Needles Wedge needles are specifically engineered to sew through thick leather and heavy materials. Their sharp, slanted tip allows them to penetrate multiple layers without causing fraying or tearing. These needles are ideal for projects that involve thick hides or multiple layers of leather.

2. Ballpoint Needles For softer leather or suede, ballpoint needles can also be useful. These needles have a rounded tip that gently pushes the fibers apart rather than cutting through them, making them suitable for delicate materials that might otherwise fray with a sharper needle.

3. Universal Needles While not exclusively for leather, universal needles can be employed for lighter leather projects. They have a slightly rounded point which makes them versatile for various fabrics, including leather and cotton blends.

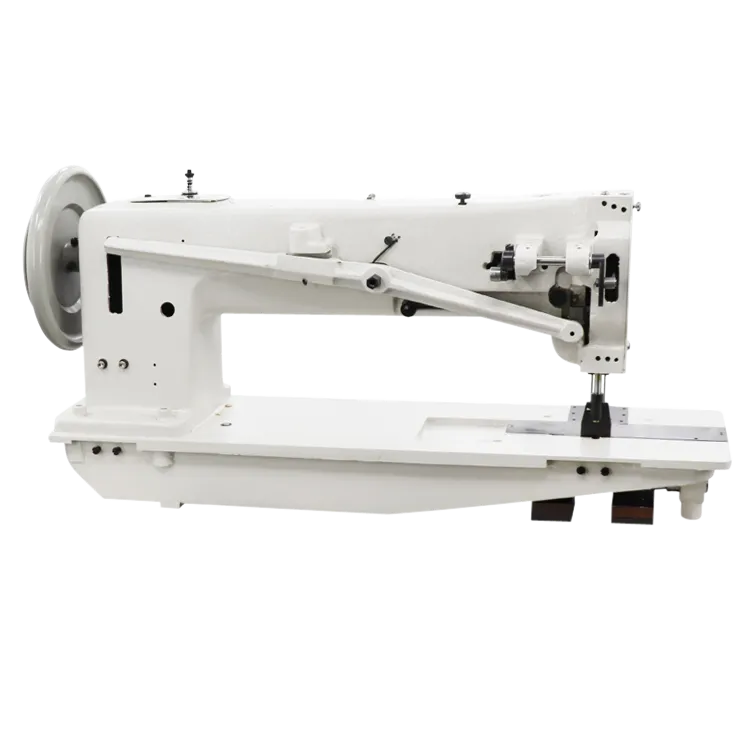

industrial sewing machine needles for leather

Selecting the Right Needle Size

Choosing the appropriate needle size is just as crucial as selecting the correct type. The size of the needle is determined by its diameter, and this should match the thickness of the leather being used. Thicker leather requires larger needles, while thinner leather can be sewn with smaller needles. Using a needle that is too large can create holes that are too big, while a needle that is too small may struggle to penetrate the leather properly, resulting in skipped stitches and uneven seams.

Maintenance and Care

Proper maintenance of sewing machine needles is vital for consistent performance. Leather needles can dull over time, especially when sewing through tough materials. Regularly inspecting needles and replacing them at the first sign of wear can help prevent damage to both the needle and the leather. Additionally, ensuring that the sewing machine is well-maintained and properly threaded enhances the sewing experience and outcome.

Conclusion

In summary, selecting the right industrial sewing machine needles for leather is a critical step in the leatherworking process. By understanding the types of needles available, selecting the appropriate size, and maintaining them effectively, leather artisans can ensure precision and quality in their projects. Investing time and effort into this aspect of leatherwork not only enhances the quality of the finished product but also elevates the craftsmanship involved in creating leather goods.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025