Types of Industrial Sewing Feet for Various Applications and Their Benefits

Understanding Industrial Sewing Feet A Key to Precision and Efficiency

In the realm of industrial sewing, the choice of equipment can significantly impact the quality and efficiency of production. One of the most critical components of sewing machines is the sewing foot, often referred to as the presser foot. Understanding the various types of industrial sewing feet can empower manufacturers to enhance their sewing processes, achieve precise results, and cater to diverse fabric types.

What is an Industrial Sewing Foot?

An industrial sewing foot is a specialized attachment on a sewing machine that holds the fabric in place during the stitching process. Unlike domestic sewing machines, industrial machines are specifically designed for high-volume production and often require different types of feet to meet various sewing needs. Each type of sewing foot serves a distinct purpose, allowing for greater versatility in the types of stitches that can be produced.

Types of Industrial Sewing Feet

1. All-Purpose Foot This is the most commonly used foot and is ideal for straight stitching. It provides a good hold on a variety of fabric types, making it a staple for general sewing tasks.

2. Zipper Foot Specifically designed for sewing zippers, this foot allows the needle to stitch closely to the coils of the zipper. It comes in two varieties one that can be used on the left side of the zipper and another on the right, facilitating easy application of any type of zipper.

3. Walking Foot Essential for handling multiple layers of fabric or thick materials, the walking foot features an additional set of feed dogs that help pull the fabric through evenly. This prevents uneven stitching and is employed in quilting and heavy-duty sewing.

4. Buttonhole Foot This foot simplifies the process of creating buttonholes. It usually features a guide that allows sewists to adjust the size of the hole according to the button being used, resulting in a professional finish.

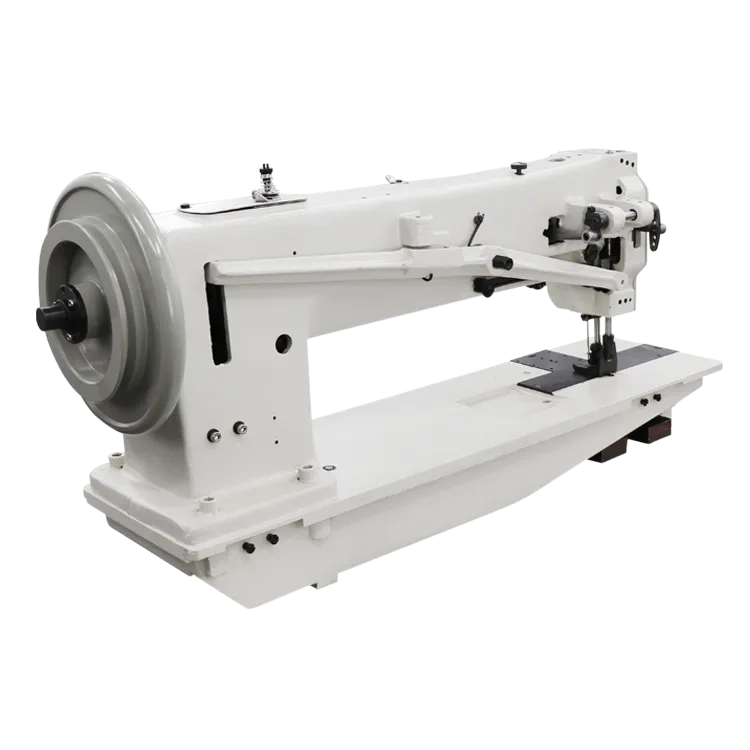

industrial sewing foot

5. Rolled Hem Foot Ideal for creating tidy hems on lightweight fabrics, this foot rolls the edge of the fabric under before sewing it in place, producing a delicate, clean finish perfect for garments like dresses and blouses.

6. Teflon Foot This foot is designed for sewing materials that are prone to sticking, such as leather or vinyl. With its smooth, non-stick surface, it allows these fabrics to glide effortlessly under the needle.

7. Free Motion Foot Primarily used in quilting and fabric art, this foot allows the sewist to move the fabric freely in any direction. It’s invaluable for intricate designs and detailed stitching.

The Importance of Choosing the Right Sewing Foot

Choosing the correct industrial sewing foot is vital for efficiency and quality. Using the wrong foot can lead to fabric damage, uneven stitches, and increased production time. For instance, attempting to sew heavy fabrics with a standard foot may cause the needle to break or the fabric to shift, leading to inaccuracies. Conversely, employing the right sewing foot can significantly speed up processes, enhance stitch quality, and reduce fabric wastage.

Maintenance and Care

Maintaining sewing feet is essential for ensuring longevity and optimal performance. Regular cleaning to remove fabric lint and debris is crucial, as is checking for wear and tear. Each type of foot may have unique care requirements, so it’s vital for operators to consult their machine’s manual for specific guidelines.

Conclusion

In conclusion, industrial sewing feet are indispensable tools that can drastically influence the efficiency and quality of sewing operations. By understanding the various types of sewing feet available and their applications, manufacturers can make informed decisions that enhance production capabilities. As the textile industry continues to evolve, the importance of precision sewing will only grow, making the mastery of industrial sewing feet an essential skill for modern sewists. With the right equipment, any sewing project can achieve the desired result—be it speed, precision, or the ability to work with a range of materials.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025