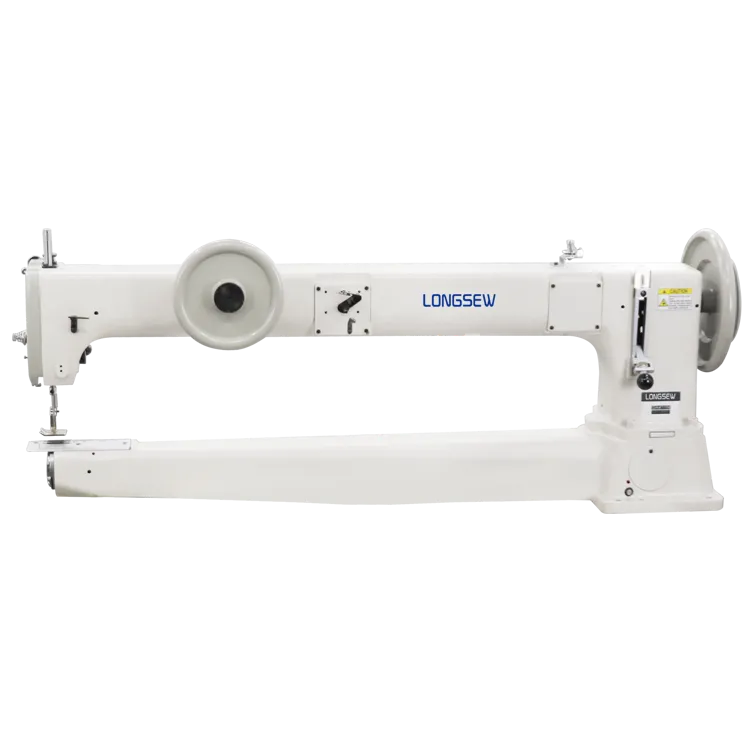

industrial sewing foot

Understanding Industrial Sewing Feet Essential Tools for Precision and Efficiency

In the world of industrial sewing, the right tools can significantly impact both the quality of the finished product and the efficiency of the production process. Among these tools, the sewing foot stands out as an indispensable accessory that can drastically enhance the capabilities of industrial sewing machines. This article will delve into the various types of industrial sewing feet, their applications, and the benefits they bring to sewing operations.

What Are Industrial Sewing Feet?

Industrial sewing feet, often referred to as presser feet, are attachments that help hold the fabric in place during stitching. Unlike standard sewing feet used in home sewing machines, industrial sewing feet are designed to withstand the rigors of high-speed sewing and can accommodate a wide range of heavy-duty fabrics, such as leather, denim, and canvas. These specialized feet allow for precise control of the fabric feed, resulting in cleaner, more accurate stitches.

Types of Industrial Sewing Feet

1. Walking Foot This type of foot is essential when working with multiple layers of fabric or slippery materials. The walking mechanism ensures that the upper and lower layers of fabric are fed simultaneously, preventing uneven feeding and shifting. This makes it perfect for quilting and sewing thick fabrics.

2. Zipper Foot As the name suggests, a zipper foot is designed for installing zippers with precision. Its narrow profile allows the needle to get close to the zipper teeth, enabling a clean finish. It is an essential tool for garment makers and those in the upholstery industry.

3. Buttonhole Foot This foot is tailored for creating uniform buttonholes. With its guide mechanism, users can achieve consistent lengths and widths, a necessity for professional finishes. This foot is especially useful in tailoring and custom garment production.

4. Teflon Foot Ideal for sewing sticky materials such as vinyl and leather, the Teflon foot features a non-stick surface that prevents fabrics from adhering to the foot. This ensures smooth feeding and stitching, which is crucial when working with challenging materials.

5. Embroidery Foot This type of foot enables intricate stitching patterns and is essential for machine embroidery. The open design allows for better visibility as users create detailed designs on fabric.

industrial sewing foot

6. Overlock Foot Commonly used in sergers, the overlock foot facilitates the finishing of raw edges of fabric. It helps in achieving a professional look by preventing fraying and ensuring durability in seams.

Benefits of Using Industrial Sewing Feet

The advantages of using specialized industrial sewing feet extend beyond just convenience. Here are some key benefits

- Precision The right sewing foot allows for precise stitching, ensuring that seams are straight and professional-looking. This is particularly critical in the fashion industry, where the quality of the finish can make or break a garment.

- Speed Industrial sewing operations often prioritize efficiency. Specialized feet can help speed up production by allowing for quicker sewing techniques, reducing the time spent adjusting fabric.

- Versatility With a variety of sewing feet available, industrial sewists can tackle different techniques and materials without needing to invest in additional machines. This versatility enhances the capability of a single industrial sewing machine.

- Reduced Wear and Tear Using the appropriate foot for specific tasks can minimize stress on both the sewing machine and the fabric, reducing the chances of damage and extending the life of both the machine and materials.

Conclusion

In conclusion, industrial sewing feet are vital tools that significantly contribute to the quality and efficiency of sewing operations. By understanding the various types of feet available and their specific applications, sewists can optimize their workflow and achieve professional results. Whether one is working in garment manufacturing, upholstery, or custom sewing, investing in the right sewing feet is a step toward enhanced productivity and superior craftsmanship. As industries continue to evolve, the importance of specialized tools such as industrial sewing feet will remain a cornerstone of quality sewing practices.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025