Mar . 05, 2025 04:41

Back to list

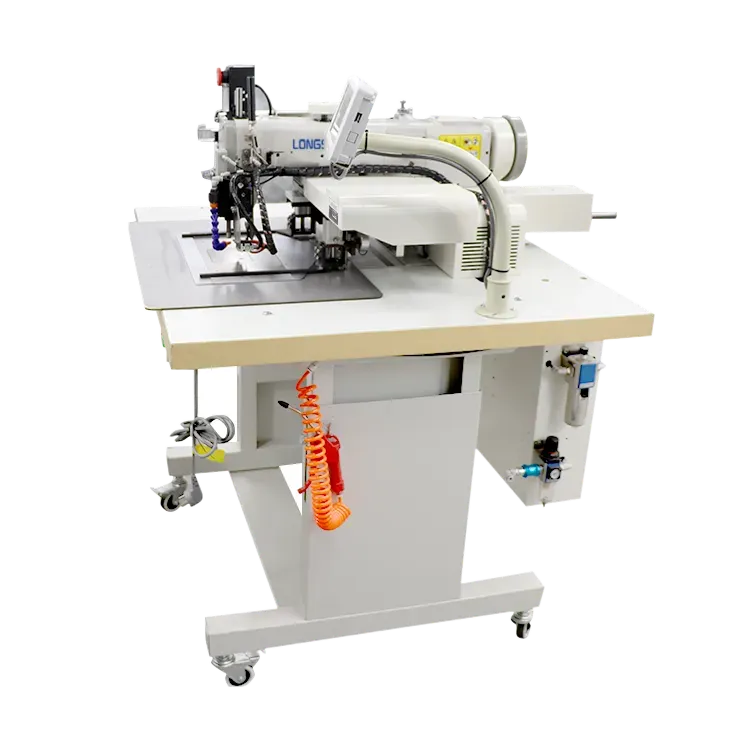

overlock sewing machine industrial

An industrial overlock machine, a quintessential tool in garment production, offers unparalleled efficiency and durability to manufacturing processes. Here, we unravel the essential aspects that make it a vital investment for businesses aiming to enhance their production capabilities while maintaining high-quality standards.

From a technical prowess standpoint, understanding the intricacies of setting up and maintaining an industrial overlock machine is vital. Proper threading, lubrication, and timely maintenance are essential skills operators must possess to ensure optimal performance. Many manufacturers offer training to guarantee that industrial facilities maximize the benefits of these machines while minimizing downtime and costly repairs. The integration of industrial overlock machines into a production line also requires attention to worker ergonomics and safety. Machines should be installed at the correct height and proximity to ensure operator comfort during long shifts, thus preventing repetitive strain injuries. Moreover, modern overlock machines often come with built-in safety features, such as finger guards and emergency stop buttons, adding an extra layer of security. As the fashion industry increasingly leans towards sustainable practices, many industrial overlock machines now offer eco-friendly options. Some models are designed to consume less energy or are compatible with organic threads and fabrics. Choosing such machines not only addresses environmental concerns but also appeals to eco-conscious consumers, potentially expanding market reach. In conclusion, the investment in an industrial overlock machine should be seen not merely as a purchase but as a strategic enhancement to a business's manufacturing capabilities. The machine's ability to deliver precise, durable seams at scale, combined with its technological advancements, positions it as an indispensable asset in the competitive textile production landscape. By investing in quality equipment, businesses are better equipped to meet the growing demands for quality and sustainability, securing their position as leaders in the garment industry.

From a technical prowess standpoint, understanding the intricacies of setting up and maintaining an industrial overlock machine is vital. Proper threading, lubrication, and timely maintenance are essential skills operators must possess to ensure optimal performance. Many manufacturers offer training to guarantee that industrial facilities maximize the benefits of these machines while minimizing downtime and costly repairs. The integration of industrial overlock machines into a production line also requires attention to worker ergonomics and safety. Machines should be installed at the correct height and proximity to ensure operator comfort during long shifts, thus preventing repetitive strain injuries. Moreover, modern overlock machines often come with built-in safety features, such as finger guards and emergency stop buttons, adding an extra layer of security. As the fashion industry increasingly leans towards sustainable practices, many industrial overlock machines now offer eco-friendly options. Some models are designed to consume less energy or are compatible with organic threads and fabrics. Choosing such machines not only addresses environmental concerns but also appeals to eco-conscious consumers, potentially expanding market reach. In conclusion, the investment in an industrial overlock machine should be seen not merely as a purchase but as a strategic enhancement to a business's manufacturing capabilities. The machine's ability to deliver precise, durable seams at scale, combined with its technological advancements, positions it as an indispensable asset in the competitive textile production landscape. By investing in quality equipment, businesses are better equipped to meet the growing demands for quality and sustainability, securing their position as leaders in the garment industry.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025