Affordable Prices for Industrial Overlock Machines in Today’s Market

Understanding Industrial Overlocker Prices A Comprehensive Guide

Industrial overlockers, often referred to as sergers, are essential machinery in textile and garment production. They serve a myriad of functions, from finishing edges and preventing fraying to sewing seams and enhancing the overall quality of a garment. However, when it comes to investing in an industrial overlocker, many business owners find themselves grappling with a crucial question how much should I expect to pay? This article will explore the factors influencing industrial overlocker prices, the different types available, and some tips on selecting the right one for your business needs.

Factors Affecting Industrial Overlocker Prices

1. Brand Reputation Well-established brands such as Juki, Brother, and Bernina typically charge a premium for their machines due to their reputation for quality and durability. Purchasing a machine from a reputable brand can sometimes be more beneficial in the long run, even if the initial investment is higher.

2. Machine Features Features significantly impact pricing. Basic overlockers may include essential functions like overcasting and seaming, while more advanced models may offer additional capabilities such as differential feed, automatic thread tension adjustment, and even embroidery options. The more features a machine has, the higher the price is likely to be.

3. Type of Overlocker Industrial overlockers come in various types, including 3-thread, 4-thread, and 5-thread machines. A 3-thread overlocker is generally the most affordable, while 5-thread models, which provide maximum seam strength and versatility, are usually priced at a premium. Understanding the types available can help narrow down options based on your budget and requirements.

4. Automation The level of automation influences prices significantly. Fully automated machines can handle complex tasks, reducing the amount of manual labor needed, thereby justifying a higher cost. However, for small-scale operations, a less automated model may suffice, keeping costs in check.

5. Capacity and Speed Higher-capacity machines that can handle larger volumes of fabric at faster speeds are typically more expensive. If your business requires a machine that can operate continuously or at high speed, it is important to factor this into your budget.

6. Country of Manufacture The origin of the machine can also affect its price. Machines manufactured in countries with high labor and production costs tend to be more expensive than those produced in regions with lower operational costs.

Average Price Range

industrial overlocker prices

The price of industrial overlockers can vary widely. On the lower end, basic models may start around $300 to $600. Mid-range machines, which offer more functionality and durability, typically fall into the $600 to $1,500 range. High-end, specialized models can exceed $1,500 and go upwards to $5,000 or more, especially those tailored for specific industries like fashion design or high-volume production.

Tips for Choosing the Right Machine

1. Assess Your Needs Before making a purchase, evaluate the specific requirements of your business. Determine the types of fabrics you will be working with and the volume of production. This will guide you in selecting a machine that fits your operational demands without overspending.

2. Budget Wisely Establish a budget that includes not only the purchase of the machine but also ongoing costs such as maintenance, threading materials, and potential future upgrades.

3. Research and Reviews Conduct thorough research on various models and brands. Read customer reviews, watch demonstrations, and compare features to ensure you are making an informed decision.

4. Consider Resale Value Investing in a well-known brand can also provide a good resale value down the line. Should your needs change, you can recover a portion of your initial investment.

5. Seek Expert Advice Don’t hesitate to consult with industry professionals or fellow business owners. They can provide insights based on experience that may prove invaluable in your decision-making process.

Conclusion

Investing in an industrial overlocker is a significant decision that can influence the efficiency and quality of your production line. By understanding the factors that affect prices and carefully assessing your needs, you can make an informed choice that aligns with your business goals. Whether you opt for a budget-friendly model or a high-end machine, the right overlocker will ultimately contribute to the success and growth of your garment production operations.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

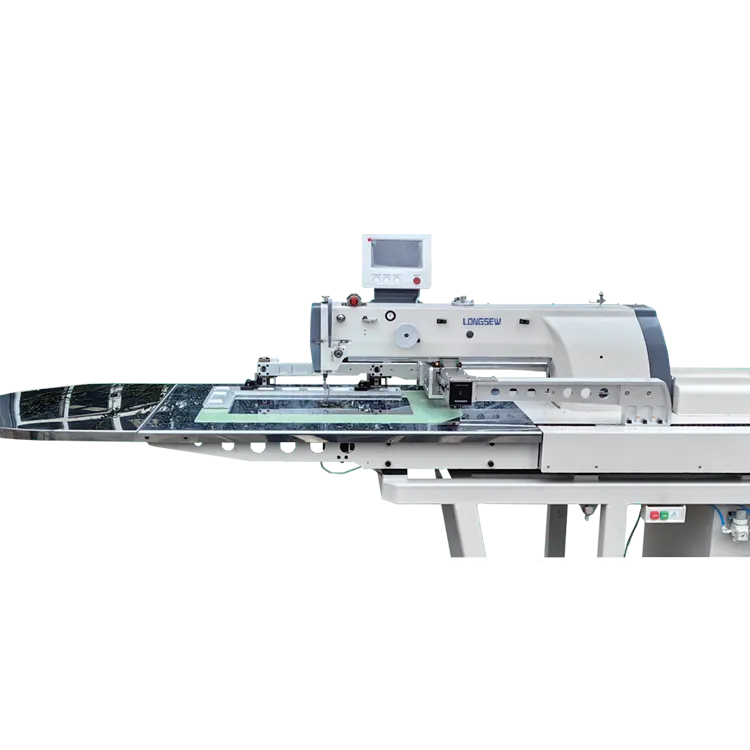

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025