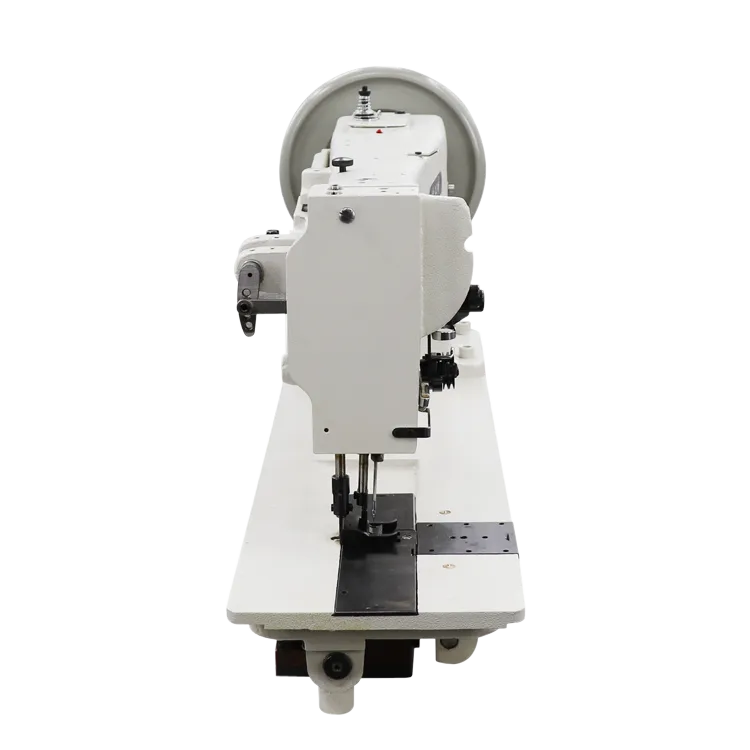

Industrial Sewing Machine for Lockstitch Applications and Efficient Fabric Production Techniques

The Industrial Lockstitch Sewing Machine An Essential Tool in Modern Textiles

The industrial lockstitch sewing machine is a cornerstone of the textile and garment industry, revolutionizing how fabrics are stitched together. Created to enhance productivity and efficiency, this machine has become indispensable for manufacturers around the globe.

At its core, the lockstitch sewing machine operates on a simple yet effective mechanism. It employs two threads—one from a spool and the other from a bobbin—creating a tight and consistent stitch that is both durable and reliable. This method of stitching is particularly well-suited for a wide variety of fabrics, from lightweight cotton to heavy denim, making it versatile for various applications in the clothing sector.

One of the key advantages of the industrial lockstitch sewing machine is its speed. Unlike hand-stitching, which can be laborious and time-consuming, these machines can produce stitches at astonishing rates, significantly increasing the volume of output. This speed is crucial in a fast-paced industry where meeting deadlines is often imperative. With the ability to sew thousands of stitches per minute, manufacturers can keep up with demand while maintaining high-quality standards.

industrial lockstitch sewing machine

Moreover, the lockstitch is known for its strength and neatness. The interlocking of the two threads creates a stitch that is less likely to unravel, offering durability to garments that undergo frequent wear and tear. This is particularly important for items like jeans, workwear, and performance apparel, where stitch integrity is vital.

The industrial lockstitch sewing machine has also embraced technological advancements. Modern machines come equipped with features such as automatic thread trimming, electronic control systems, and programmable stitch patterns. These enhancements not only improve the efficiency of the sewing process but also facilitate precision and consistency, allowing for intricate designs and patterns that meet contemporary fashion demands.

Training operators to use these machines has become an essential aspect of production. Skilled workers who understand the nuances of machine operation and maintenance contribute greatly to the overall productivity and quality of the finished products. Companies invest in training programs to ensure their staff is proficient, thereby maximizing the return on their machinery investments.

In conclusion, the industrial lockstitch sewing machine epitomizes the intersection of technology and craftsmanship in the modern textile industry. Its speed, durability, and versatility make it an essential tool for manufacturers seeking to produce high-quality garments efficiently. As the fashion landscape continues to evolve, these machines will undoubtedly remain at the forefront, continuously shaping how we create and consume clothing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025