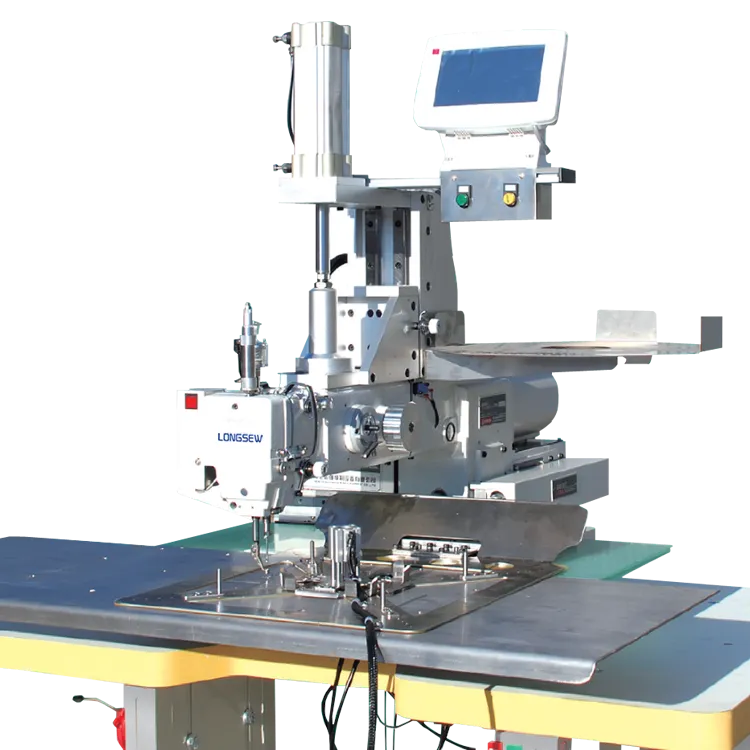

industrial lockstitch sewing machine

The Industrial Lockstitch Sewing Machine Revolutionizing the Textile Industry

The industrial lockstitch sewing machine has become an essential tool in the textile industry, transforming how garments are manufactured, altered, and repaired. With its unique design and functionality, this machinery has improved the speed and efficiency of sewing operations, allowing manufacturers to meet high demands in a competitive market.

What is a Lockstitch Sewing Machine?

A lockstitch sewing machine creates a stitch by interlocking two threads—a top thread and a bottom thread—within the fabric. The top thread is fed through a needle, while the bottom thread is delivered from a bobbin located beneath the fabric. As the needle pierces the material, it allows the top thread to loop around the bobbin thread, forming a secure stitch. This method is known for producing strong and durable seams, which is vital for the longevity and quality of garments.

History and Evolution

The origins of the lockstitch sewing machine date back to the 19th century. Before the advent of machinery, garments were hand-sewn, a labor-intensive process that could take days or even weeks to complete a single piece. The introduction of the lockstitch machine was a game-changer. Industrial revolution pioneers like Isaac Merritt Singer contributed significantly to the development and popularization of these machines in the late 1800s. With improved designs and functionalities, the lockstitch sewing machine quickly gained traction in factories, drastically reducing production times.

Characteristics of Industrial Lockstitch Machines

Modern industrial lockstitch sewing machines are equipped with various features that enhance their performance. These machines are typically characterized by high speed, often capable of sewing up to 5,000 stitches per minute, which is essential for high-volume production environments. Additionally, they often include automated features such as automatic threading, programmable stitch lengths, and tension control systems, making operations more efficient and less prone to human error.

The construction of industrial lockstitch machines also differs from domestic models. They are built to withstand heavy use, featuring more robust components and heavier frames. The durability of these machines ensures they can handle the thick and layered fabrics often encountered in industrial sewing applications, such as denim or canvas.

industrial lockstitch sewing machine

Applications

Industrial lockstitch sewing machines find extensive applications across various sectors, including apparel manufacturing, upholstery, and leather goods. In the apparel industry, these machines are commonly used to construct and finish garments, ensuring that seams are both strong and aesthetically pleasing. In the upholstery business, they are vital for sewing cushions and heavy fabrics that require durability.

Additionally, the versatility of the lockstitch design allows it to be used in creating decorative stitching and unique designs, making it an asset in fashioning high-quality garments and accessories. The machine can be easily adjusted for different sewing requirements, such as changing stitch width and length, providing seam finishes that are essential for garment finishing.

Challenges and Future Trends

Despite their many advantages, industrial lockstitch sewing machines face challenges, such as the need for constant maintenance and the potential for mechanical failure in a high-output environment. Additionally, the rise of fast fashion and the demand for quick turnaround times have led to increased pressure on manufacturers to produce garments at lightning speed.

The future of lockstitch sewing machines looks promising, with innovations on the horizon. Technologies such as computerization and automation are increasingly being integrated into sewing processes, allowing for more complex designs and improved precision. Furthermore, advancements in artificial intelligence and robotics may one day lead to fully automated sewing lines, reducing labor costs and increasing production efficiency.

Conclusion

The industrial lockstitch sewing machine has undoubtedly revolutionized the textile industry, streamlining garment production and playing a critical role in the evolution of fashion. Its unmatched reliability and robust design make it a staple in countless manufacturing environments. As technology advances, these machines will continue to evolve, adapting to new challenges and maintaining their essential position in modern manufacturing. The lockstitch machine not only represents a significant historical development in sewing technology but also symbolizes the ongoing innovation that drives the textile industry forward.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025