industrial lock stitch machine

The Industrial Lock Stitch Machine An Essential Tool for Textile Manufacturing

In the realm of textile manufacturing, the industrial lock stitch machine stands as a cornerstone of efficiency and quality. This device is renowned for its precision stitching and robust construction, making it a preferred choice for factories and workshops engaged in high-volume production. As we delve into the intricacies of this machine, we will explore its working principles, advantages, applications, and its pivotal role in the evolution of the textile industry.

Understanding the Lock Stitch Mechanism

At its core, the industrial lock stitch machine operates on a straightforward yet effective mechanism. It utilizes two threads the upper thread is drawn from a spool on the machine, while the lower thread is bobbin-based. Through a series of precise movements, the machine interlocks these two threads to create a tight, secure stitch. This double-thread configuration produces a flat, strong seam that is not only durable but also aesthetically pleasing.

Lock stitching is particularly valued for its versatility and is used in a variety of fabric types, from lightweight materials like silk to heavy-duty textiles such as denim. The stitch remains consistent and reliable, crucial for mass production where quality control is paramount.

Advantages of Industrial Lock Stitch Machines

The industrial lock stitch machine is celebrated for several advantages that make it indispensable in the textile sector

1. Durability and Reliability These machines are designed for heavy-duty use, capable of running for long hours without compromising performance. Their robust construction ensures longevity, which translates to lower operational costs over time.

2. High Speed Modern lock stitch machines can sew at remarkable speeds, often exceeding 5,000 stitches per minute. This increased productivity is vital for fulfilling large orders in a timely manner, thereby supporting the fast-paced nature of the fashion industry.

3. Versatility Whether it is a simple hem or intricate pattern work, lock stitch machines can handle a variety of stitching tasks. This versatility allows manufacturers to produce a wide range of products, from garments to upholstery, with ease.

industrial lock stitch machine

4. Quality of Stitch The lock stitch is characterized by a neat and professional appearance. Unlike some other stitching methods, it does not easily unravel, ensuring that finished products maintain their integrity after washing and wear.

Applications in the Textile Industry

The applications of the industrial lock stitch machine are vast and varied. In the garment industry, it is primarily used for sewing seams, hems, and decorative stitching. The machine is suitable for both woven and knitted fabrics, making it a staple for producing everything from casual wear to formal attire.

Beyond apparel, these machines are also utilized in home textiles, including curtains, bed linens, and upholstery. Additionally, they play a critical role in the production of accessories such as bags, belts, and hats. Their ability to create strong, reliable seams ensures that the end products are both functional and aesthetically appealing.

The Evolution of the Industrial Lock Stitch Machine

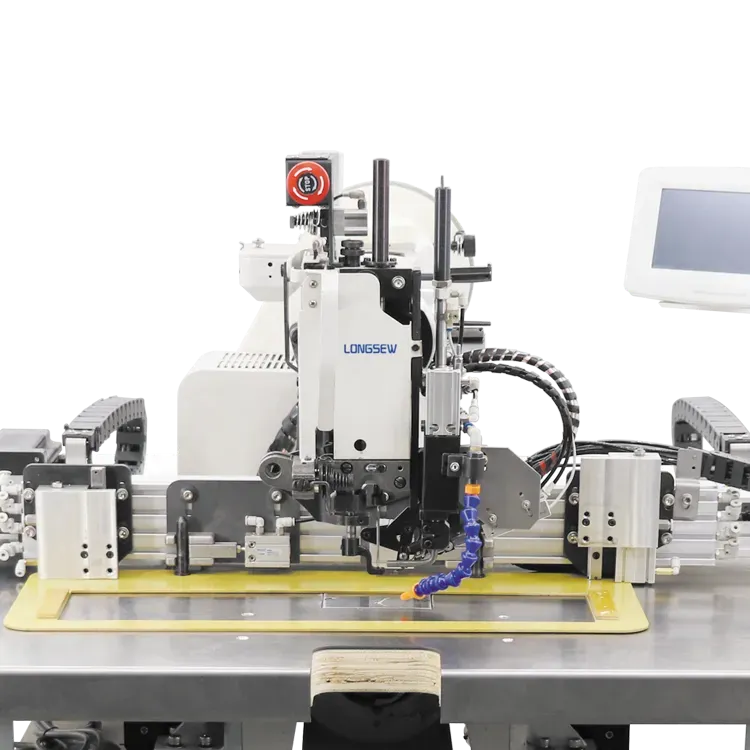

Since its inception, the industrial lock stitch machine has undergone significant advancements. Early models were mechanical, requiring substantial manual labor to operate. Today, advanced versions incorporate computerized technology, allowing for programmable stitching patterns, automated threading, and even real-time monitoring of production metrics.

These technological innovations not only enhance productivity but also improve accuracy and reduce the risk of human error. The introduction of user-friendly interfaces has made it easier for operators to manage complex tasks, ensuring that even the most intricate designs can be executed with precision.

Conclusion

The industrial lock stitch machine is more than just a sewing tool; it is an essential piece of equipment that has shaped the textile manufacturing landscape. With its high efficiency, remarkable stitch quality, and versatility, it remains a vital asset in the production process. As technology continues to advance, we can expect further innovations that will enhance the capabilities of lock stitch machines, ensuring their place in the ever-evolving world of textiles. Whether in a small workshop or a large manufacturing facility, the lock stitch machine undoubtedly plays a pivotal role in delivering quality and speed, ultimately contributing to the broader success of the textile industry.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025