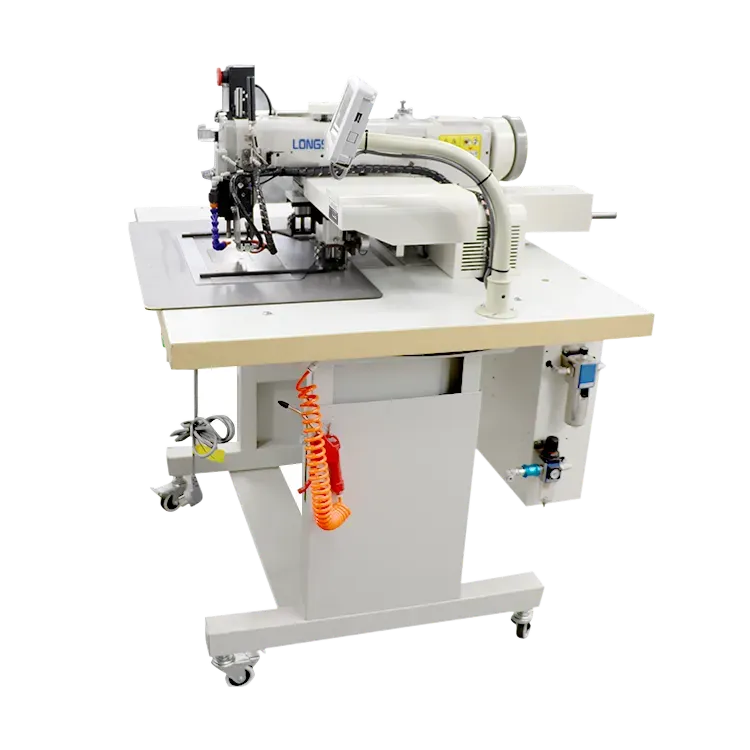

industrial leather machine

Industrial Leather Machinery Innovations and Impacts

The leather industry has long been a cornerstone of manufacturing, providing essential materials for fashion, accessories, furniture, and automotive sectors. At the heart of this industry lies a complex network of industrial leather machinery, which has evolved significantly over the years, driven by technological advancements and sustainability considerations.

Industrial leather machinery encompasses a variety of equipment used in the tanning, finishing, and processing of leather. This includes tanning machines, shaving machines, splitting machines, and finishing equipment. Each of these machines plays a crucial role in transforming raw hides into high-quality leather suitable for various applications.

One of the most significant innovations in industrial leather machinery is automation. Automated systems now streamline many processes, increasing efficiency and consistency in production. For instance, modern tanning machines equipped with computer-controlled systems ensure precise chemical dosing, which reduces waste and enhances the quality of the leather. This not only lowers production costs but also minimizes the environmental impact associated with traditional tanning methods.

industrial leather machine

Additionally, the introduction of eco-friendly machinery has become a priority in the leather industry. Many companies are investing in technologies that utilize less water and energy, aligning with global sustainability goals. For example, waterless tanning technologies and energy-efficient drying machines have emerged, significantly cutting down the ecological footprint of leather production. These innovations not only help in meeting regulatory requirements but also cater to the growing consumer demand for environmentally sustainable products.

Moreover, advancements in digital technology have improved quality control processes in leather manufacturing. High-tech scanners and sensors can detect imperfections in hides before they are processed, ensuring that only the best materials are used. This level of precision not only enhances the quality of the final product but also reduces material wastage.

The impact of innovative industrial leather machinery extends beyond production efficiency and sustainability; it also fosters creativity and diversity in design. With new capabilities in leather processing, manufacturers can experiment with textures, colors, and patterns, leading to unique products that differentiate themselves in a competitive market. This not only appeals to consumers but also allows brands to express their identity through distinctive leather goods.

In conclusion, industrial leather machinery is at the forefront of transforming the leather industry. Through automation, eco-friendly innovations, and advanced quality control, the sector is moving towards a more efficient and sustainable future. As technology continues to evolve, manufacturers are poised to meet the challenges of modern production while embracing the rich tradition of leather craftsmanship. The future of leather manufacturing looks promising, with innovations that will further enhance both its artistic and industrial aspects.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025