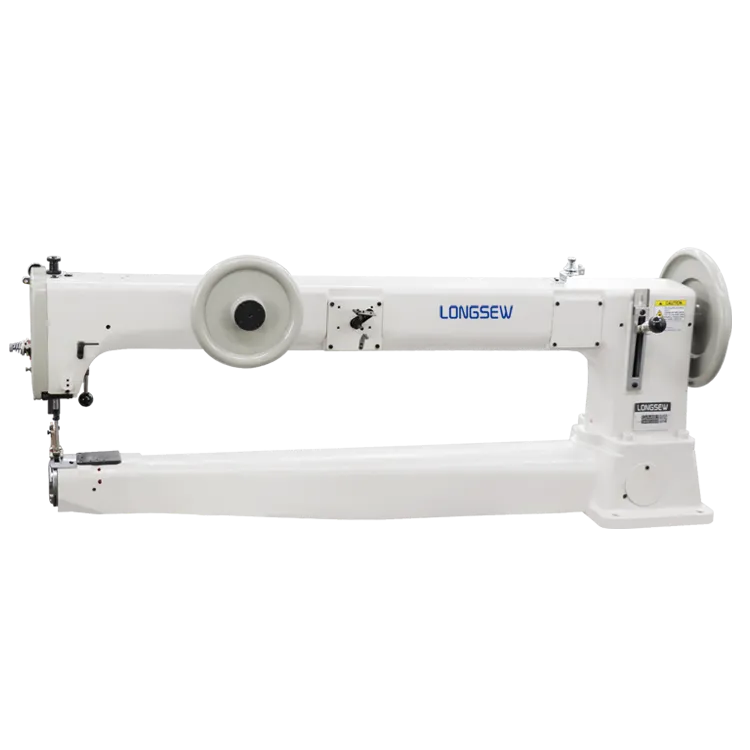

industrial leather machine

Industrial Leather Machines Advancements and Applications

The leather industry has evolved significantly over the years, driven by technological advancements and the demand for high-quality products. Central to this evolution are industrial leather machines, which play a crucial role in various stages of leather production, from tanning to finishing. These machines not only enhance efficiency but also improve the quality of leather, catering to the diverse needs of manufacturers and consumers alike.

One of the primary functions of industrial leather machines is tanning, the process that transforms raw animal hides into durable, wearable leather. Traditional tanning methods were labor-intensive and time-consuming. However, modern machines have revolutionized this aspect of leather production. Automated tanning machines ensure uniform treatment of hides, reducing the risk of defects and enhancing leather's final quality. These machines can also optimize the use of chemicals, minimizing environmental impact, which is becoming increasingly important in today’s eco-conscious market.

After tanning, the leather must be dyed and finished. Industrial leather dyeing machines allow for precise color application, providing a consistent finish that meets stringent quality standards. These machines often feature advanced technology that ensures even distribution of dyes, which is critical for achieving the desired aesthetic and durability. Additionally, finishing machines apply protective coatings that enhance leather's longevity and resistance to wear and tear, making products more appealing to consumers.

industrial leather machine

In addition to improving the quality of leather, industrial machines also dramatically increase production speed. High-capacity stitching machines, for instance, can process large volumes of leather swiftly, allowing manufacturers to meet growing consumer demand. This automation reduces human error, streamlines workflows, and ultimately leads to cost savings. As the global demand for leather products continues to rise, these machines are increasingly recognized as essential components of modern leather manufacturing.

Moreover, the rise of smart technologies has begun to infiltrate the leather industry, with machines integrating IoT (Internet of Things) capabilities. This connectivity enables real-time monitoring of machine performance and product quality, allowing for predictive maintenance and reducing downtime. Such advancements contribute to a more efficient production process and improved resource management.

In conclusion, industrial leather machines are vital to the contemporary leather industry. They not only enhance the quality and consistency of leather products but also streamline production processes, making them indispensable for meeting modern consumer demands. As technology continues to evolve, we can expect further innovations that will further transform the leather manufacturing landscape, balancing efficiency with sustainability and quality. The future of industrial leather machinery promises to be both exciting and impactful for the industry.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025