Feb . 12, 2025 14:50

Back to list

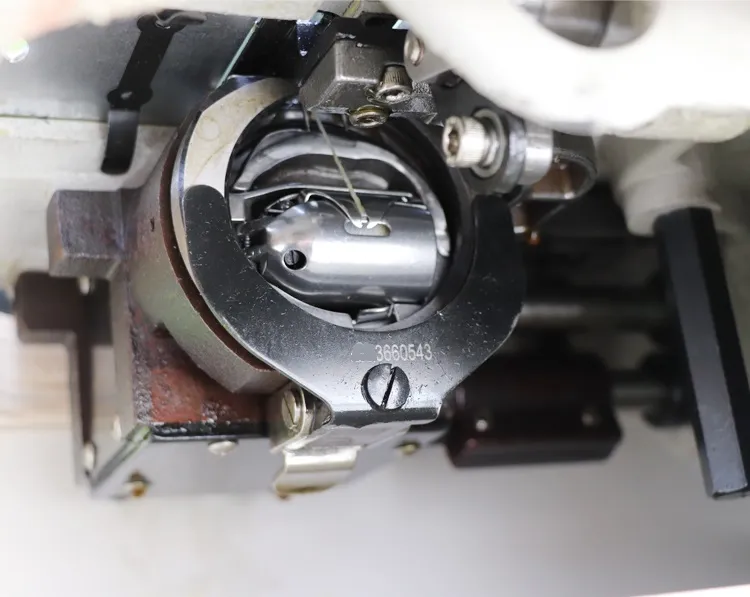

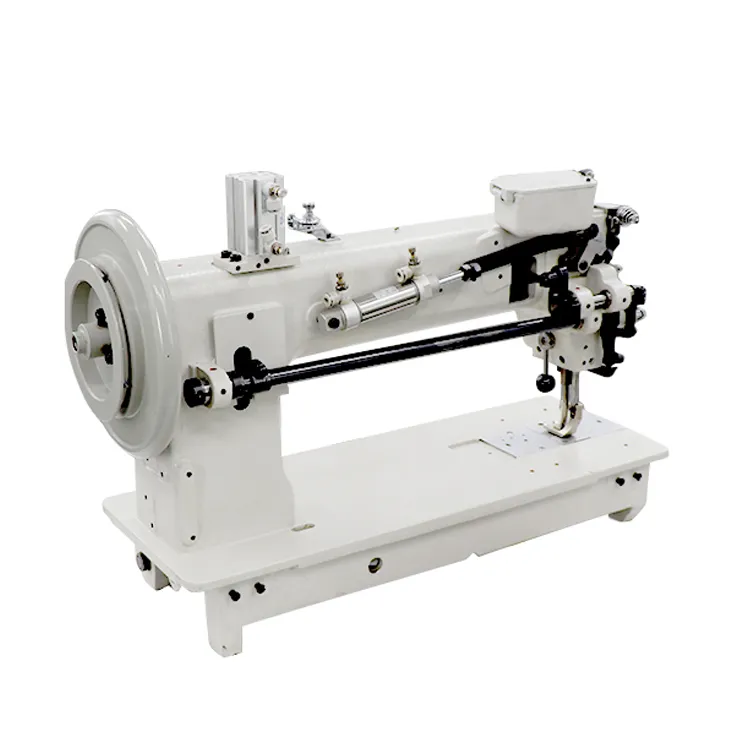

Long Arm Heavy Duty Cylinder Bed Horizontal Direction Sewing Machine For Like Boot Long Barrel Products GA411N

Industrial leather machines have revolutionized the manufacturing landscape, providing efficiency, precision, and quality to industries reliant on leather goods production. In this authoritative overview, we delve into the experience, expertise, authoritativeness, and trustworthiness of industrial leather machines, acknowledging their pivotal role in the production of leather goods across myriad sectors.

In terms of expertise, operators of industrial leather machines undergo rigorous training, ensuring they align their manual skills with the technological capabilities of the machines. This expertise allows operators to troubleshoot, maintain, and maximize machine output, safeguarding the lifespan of both the machine and the leather goods produced. Founded on decades of innovation, the development of industrial leather machines is backed by authoritative research and development from leading manufacturers. Brands like JUKI, Brother, and Dürkopp Adler have become synonymous with reliability and precision, their machines trusted worldwide due to a legacy of quality and customer satisfaction. These companies continually strive to enhance their machines through R&D, integrating AI and automation to further streamline production and improve leather adaptability. Sustainability is increasingly becoming a focal point in the development of these machines. As the leather industry faces environmental scrutiny, machine manufacturers are engineering solutions that optimize resource use and minimize environmental impact—promoting eco-friendly alternatives such as water-based glues and biodegradable materials. Trustworthiness in industrial leather machines is assured through rigorous quality control processes. Each machine is tested under various scenarios to simulate real-world applications, thereby ensuring that only top-tier machines reach factories. Furthermore, customer support from credible manufacturers includes comprehensive service packages, user training, and readily available spare parts, crucial for minimizing downtime and maintaining production schedules. In conclusion, industrial leather machines are the backbone of quality in leather goods production, imbued with the expertise, authority, and trustworthiness to meet the demands of a competitive global market. For industries relying on leather, these machines are not just an investment in technology but an investment in unparalleled craftsmanship and enduring value.

In terms of expertise, operators of industrial leather machines undergo rigorous training, ensuring they align their manual skills with the technological capabilities of the machines. This expertise allows operators to troubleshoot, maintain, and maximize machine output, safeguarding the lifespan of both the machine and the leather goods produced. Founded on decades of innovation, the development of industrial leather machines is backed by authoritative research and development from leading manufacturers. Brands like JUKI, Brother, and Dürkopp Adler have become synonymous with reliability and precision, their machines trusted worldwide due to a legacy of quality and customer satisfaction. These companies continually strive to enhance their machines through R&D, integrating AI and automation to further streamline production and improve leather adaptability. Sustainability is increasingly becoming a focal point in the development of these machines. As the leather industry faces environmental scrutiny, machine manufacturers are engineering solutions that optimize resource use and minimize environmental impact—promoting eco-friendly alternatives such as water-based glues and biodegradable materials. Trustworthiness in industrial leather machines is assured through rigorous quality control processes. Each machine is tested under various scenarios to simulate real-world applications, thereby ensuring that only top-tier machines reach factories. Furthermore, customer support from credible manufacturers includes comprehensive service packages, user training, and readily available spare parts, crucial for minimizing downtime and maintaining production schedules. In conclusion, industrial leather machines are the backbone of quality in leather goods production, imbued with the expertise, authority, and trustworthiness to meet the demands of a competitive global market. For industries relying on leather, these machines are not just an investment in technology but an investment in unparalleled craftsmanship and enduring value.

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025