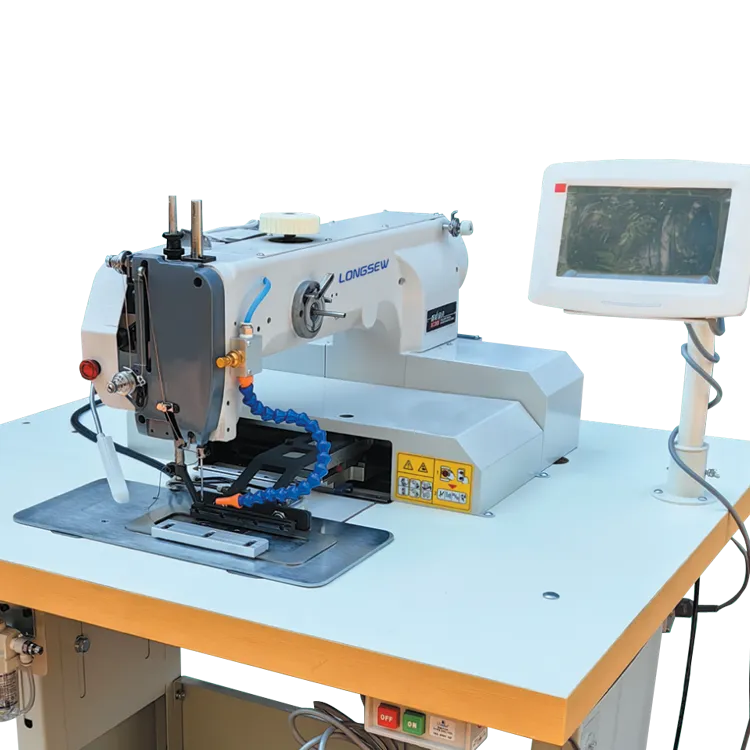

industrial cylinder sewing machine

The Evolution and Significance of Industrial Cylinder Sewing Machines

In the world of textile manufacturing and garment production, industrial cylinder sewing machines play a crucial role. These specialized machines are designed to enhance efficiency, precision, and versatility, significantly impacting how fabrics are sewn into finished products. This article explores the evolution, functionality, and importance of industrial cylinder sewing machines in the textile industry.

Understanding the Cylinder Sewing Machine

Industrial cylinder sewing machines are distinguished by their cylindrical arm design, which allows for sewing in tight spaces and on circular or tubular fabrics. This makes them an essential tool for producing a wide variety of items, from clothing to upholstery. Unlike traditional flat-bed sewing machines, cylinder machines are particularly well-suited for tasks that require sewing around edges or within the confines of small openings, such as cuffs, collars, and pockets.

Historical Context

The origins of sewing machines date back to the 19th century, with the first practical sewing machine being patented by Elias Howe in 1846. The evolution of these machines continued throughout the century, leading to the invention of various specialized models, including the cylinder sewing machine. The design was primarily aimed at improving productivity in factories that operated on large scales, responding to the growing demand for faster and more efficient manufacturing processes.

As the textile industry expanded, particularly during the industrial revolution, the need for machines that could handle diverse sewing tasks became imperative. The cylinder sewing machine emerged as a solution, offering increased adaptability and faster sewing speeds. This innovation played a significant role in mechanizing the garment industry, drastically reducing production time while improving accuracy and consistency.

Key Features and Advantages

One of the standout features of industrial cylinder sewing machines is their ability to sew intricate designs with precision. They are equipped with specialized attachments and needles that allow for a wide variety of stitch types, accommodating diverse fabrics and applications. The adjustable speed settings enable operators to control the stitching process, ensuring quality output regardless of the fabric thickness or type.

industrial cylinder sewing machine

Moreover, the cylindrical arm design minimizes fabric handling, making it easier to maneuver materials without the risk of misalignment. This design not only enhances sewing efficiency but also improves safety by reducing the chances of accidents common in flat-bed machines. Additionally, many modern cylinder sewing machines incorporate automated functions, such as thread trimming and backstitching, to streamline the sewing process further.

Applications in the Industry

The applications of industrial cylinder sewing machines are extensive. They are commonly used in the production of garments like pants, jackets, and sportswear, which often require sewing in complex shapes. Additionally, they are essential in other sectors, such as leather goods manufacturing, where precision stitching is crucial for product durability and aesthetics.

In the fashion industry, the ability to create unique designs quickly gives brands a competitive edge. The versatility of cylinder sewing machines allows designers to experiment with different fabrics and stitching techniques, facilitating innovation in clothing styles and functionality.

The Future of Cylinder Sewing Machines

As technology continues to evolve, so do the capabilities of industrial cylinder sewing machines. Advancements in computer-controlled systems and robotics are enabling even higher levels of automation and precision. These technologies not only enhance productivity but also contribute to sustainable practices within the textile industry by minimizing waste during the production process.

Looking ahead, the integration of smart technology, such as IoT connectivity, is set to revolutionize how these machines operate. Manufacturers can monitor performance in real-time, leading to proactive maintenance and optimized workflow. This evolution will likely result in reduced downtime and increased operational efficiency, further solidifying the importance of cylinder sewing machines in the industry.

Conclusion

Industrial cylinder sewing machines have become indispensable tools in the textile and garment manufacturing sectors. Their unique design and functionality allow for unparalleled precision and efficiency, making them a favorite among manufacturers worldwide. As the industry continues to innovate, these machines will adapt to meet new challenges and trends, ensuring they remain at the forefront of textile production for years to come. Their evolution not only encapsulates advancements in technology but also highlights the ongoing commitment to quality and efficiency in the fabric of our daily lives.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025