High-Performance CNC Sewing Machines for Industrial Applications and Efficiency Optimization

The Rise of Industrial CNC Sewing Machines

In the ever-evolving world of textile manufacturing, industrial CNC (Computer Numerical Control) sewing machines have emerged as a transformative force. These advanced machines combine precision engineering with modern technology, offering a range of benefits that enhance productivity and quality in clothing production, upholstery, and various textile applications. As industries strive for higher efficiency and lower costs, the adoption of CNC sewing machines has become increasingly prevalent.

What is an Industrial CNC Sewing Machine?

An industrial CNC sewing machine operates on a computerized system that allows for automated sewing tasks. Unlike traditional sewing machines, which require manual input for each stitch and task, CNC machines are programmed to execute complex patterns and designs autonomously. This technology enables manufacturers to achieve uniform stitches and intricate designs with remarkable speed and accuracy.

Key Benefits

1. Increased Productivity CNC sewing machines can operate continuously without the need for breaks, leading to a significant boost in output. Their ability to swiftly execute repeated tasks allows manufacturers to meet high production demands without sacrificing quality.

2. Precision and Consistency With the ability to program specific stitch patterns and qualities, CNC machines ensure that every piece produced is identical. This level of precision is particularly valuable in industries where consistency is essential, such as fashion and automotive upholstery.

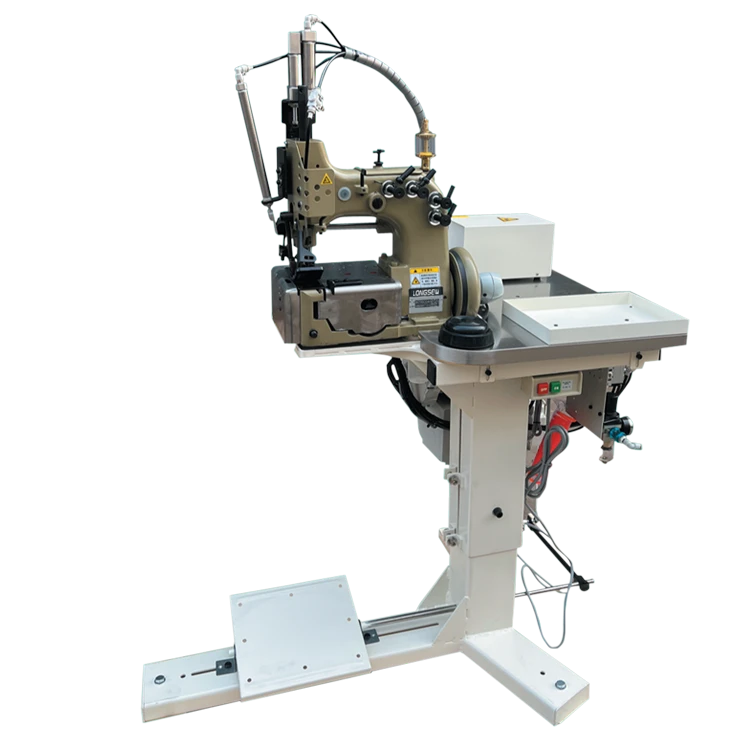

industrial cnc sewing machine

3. Reduced Labor Costs By automating sewing processes, companies can reduce the reliance on skilled labor for repetitive tasks. This not only lowers labor costs but also allows skilled workers to focus on more complex and creative aspects of production.

4. Versatility Modern CNC sewing machines are designed to handle a wide variety of fabrics and sewing techniques. From delicate silks to heavy-duty canvases, these machines can adapt to different materials, making them suitable for diverse industries.

5. Enhanced Design Capabilities The integration of CAD (Computer-Aided Design) software with CNC machines enables designers to experiment with intricate patterns and styles that would be nearly impossible to replicate manually. This capability opens up new avenues for creativity and innovation in textile design.

Challenges and Considerations

While the advantages of CNC sewing machines are substantial, there are certain challenges to consider. The initial investment for these machines can be significantly higher than conventional sewing machines, which may deter some smaller manufacturers. Additionally, the operation of CNC machines requires a certain level of technical knowledge, necessitating training for operators.

Conclusion

The rise of industrial CNC sewing machines marks a significant advancement in the textile manufacturing industry. By merging the art of sewing with cutting-edge technology, these machines facilitate greater efficiency, consistency, and creativity. As market demands continue to evolve, the integration of CNC technology is likely to become a standard practice in the quest for quality and efficiency in production. With ongoing advancements in technology, the future of industrial sewing looks poised for further innovation, promising an exciting era for manufacturers and consumers alike.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025