High-Efficiency FIBC Bag Sewing Machine – Longsew | Precision Industrial Solutions

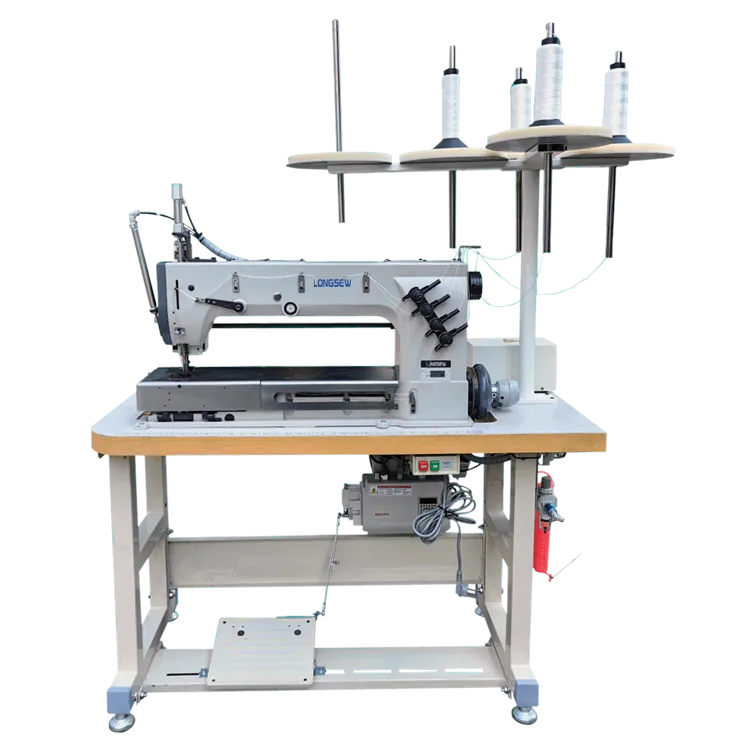

High-Efficiency FIBC Bag Sewing Machine for Industrial Applications – LS5800-1/LS5800 by Longsew

Discover the cutting-edge FIBC Bag Sewing Machine LS5800-1/LS5800 designed to revolutionize your bulk bag manufacturing processes. Engineered by Longsew, a leading manufacturer of industrial sewing solutions, this machine combines precision, durability, and efficiency to meet the demands of modern production lines.

Product Overview

The LS5800-1/LS5800 is a specialized sewing machine tailored for Q-type big bag baffles. It utilizes single and double needle chain stitch technology to ensure robust and consistent seams, critical for the structural integrity of bulk bags. This machine is ideal for industries requiring high-volume production of FIBC (Flexible Intermediate Bulk Containers), such as agriculture, chemical, and construction sectors.

Key Features

- High-Speed Operation: Achieve up to 2000 stitches per minute, significantly reducing production time.

- Durability: Constructed with heavy-duty components to withstand continuous industrial use.

- Adjustable Settings: Customizable stitch length and tension for various fabric types and thicknesses.

- User-Friendly Interface: Intuitive control panel for easy operation and maintenance.

Market Demand and Industry Challenges

The demand for FIBC bags has surged due to their versatility in transporting bulk materials. However, traditional sewing methods often face challenges such as inconsistent seam quality and slow production rates. The LS5800-1/LS5800 addresses these issues with its advanced technology, ensuring precise stitching and faster output, thereby enhancing overall productivity.

Company Expertise and Innovation

With over 20 years of experience, Longsew has established itself as a trusted name in industrial sewing machinery. Our commitment to innovation is reflected in the LS5800-1/LS5800, which incorporates feedback from global clients to deliver optimal performance. Our R&D team continuously invests in improving machine efficiency and user experience.

Product Performance and Customer Testimonials

Users of the LS5800-1/LS5800 report a 30% increase in production efficiency and a 20% reduction in material waste. One client, a major agricultural supplier, stated, "This machine has transformed our workflow, allowing us to meet tight deadlines without compromising quality." Another user, a chemical manufacturer, praised the machine's reliability and ease of integration into their existing setup.

Usage Guidelines and Custom Solutions

To maximize the machine's potential, follow these steps:

- Preparation: Ensure the fabric is properly aligned and tensioned.

- Operation: Adjust the stitch settings based on the material thickness.

- Maintenance: Regularly clean and lubricate the machine to prevent wear and tear.

Longsew offers tailored solutions to accommodate specific production needs, including custom stitching patterns and machine configurations.

Safety and Compliance

The LS5800-1/LS5800 adheres to international safety standards, including CE and ISO certifications. Its design minimizes the risk of accidents, ensuring a safe working environment for operators.

Packaging and Logistics

Each machine is securely packaged in a wooden crate to protect against damage during transit. Longsew provides global shipping options, with dedicated logistics partners to ensure timely delivery.

Customer Support and After-Sales Service

Longsew offers comprehensive support, including 24/7 technical assistance, on-site installation, and training programs. Our dedicated team ensures that clients receive the necessary guidance to optimize machine performance.

Contact Us

Ready to elevate your production capabilities? Contact Longsew today for a personalized consultation. Visit our website or reach out via phone at +86-21-5588-XXXX to learn more about the LS5800-1/LS5800 and how it can benefit your business.

FAQ

Q: What materials can the LS5800-1/LS5800 handle?

A: It is designed for heavy-duty fabrics such as jute, polyester, and woven polypropylene.

Q: How long does it take to install the machine?

A: Installation typically takes 1-2 days, depending on the facility's setup.

Q: Is training provided?

A: Yes, Longsew offers on-site training to ensure operators are fully proficient.

Conclusion

The LS5800-1/LS5800 is a game-changer for bulk bag manufacturers. With its advanced features, reliability, and exceptional support, Longsew delivers a solution that meets and exceeds industry expectations. Explore our website to discover how this machine can enhance your operations.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025