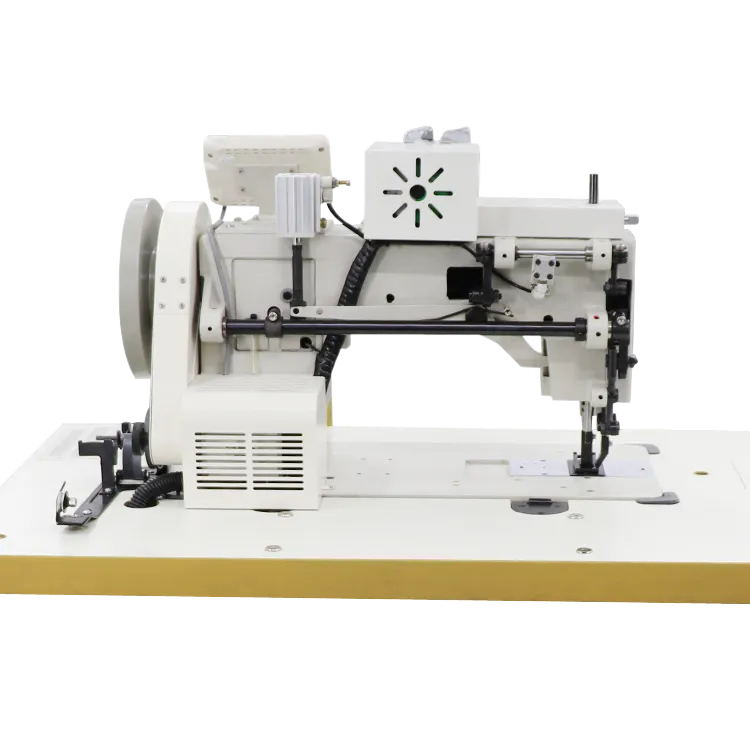

heavy material sewing machine

Understanding Heavy Material Sewing Machines The Key to Durable Fabrication

In the world of textile production, heavy material sewing machines play an essential role in ensuring that sturdy and resilient fabrics are constructed efficiently and effectively. As industries increasingly demand durable products, the need for specialized sewing equipment has become more pronounced. This article explores the significance of heavy material sewing machines, their unique features, and their applications across various sectors.

The Importance of Heavy Material Sewing Machines

Heavy material sewing machines are specifically designed to handle thick, tough fabrics such as leather, denim, canvas, and other heavy-duty materials. These materials are often used in industries like construction, military, automotive, and upholstery, where durability and strength are paramount. Unlike standard sewing machines, which are built for lighter fabrics, heavy material sewing machines boast enhanced capabilities in terms of stitch quality, power, and durability.

One key aspect that sets these machines apart is their robust construction. Heavy material sewing machines are typically equipped with a heavy-duty frame and powerful motors that allow them to penetrate multiple layers of thick fabric with ease. This capability minimizes the risk of needle breakage and ensures consistent stitch formation, even under the stress of heavy materials.

Unique Features of Heavy Material Sewing Machines

1. High Needle Penetration Power Heavy material sewing machines are engineered to accommodate specialized needles that can handle tough materials. These needles often have a thicker shaft and a larger eye, which prevents breakage while allowing for the use of robust threads.

2. Adjustable Presser Feet They usually come equipped with adjustable presser feet to manage various fabric thicknesses. This feature ensures that the material is fed smoothly and evenly through the machine, preventing shifting or puckering during stitching.

heavy material sewing machine

3. Heavy-Duty Threads To complement heavy materials, these machines utilize thicker threads, which can withstand tensile strength and provide a secure hold. Many models allow for a wider range of thread types, including heavy-duty polyester and nylon, to meet diverse manufacturing needs.

4. Variable Speed Control Operators can often control the speed, allowing for precision sewing at a comfortable pace. This is particularly useful when working with heavy fabrics, as it enables greater control and reduces the chances of mistakes.

5. Tension Adjustment The ability to adjust tension settings is crucial in sewing heavy materials. Appropriate tension ensures that stitches are neither too tight—risking fabric damage—nor too loose, which could compromise the integrity of the seam.

Applications Across Industries

Heavy material sewing machines are invaluable in numerous applications. In the automotive sector, they are used to fabricate seat covers, airbags, and convertible tops. The military employs these machines for uniforms, tents, and gear where resilience is crucial. Upholstery work also benefits significantly, as these machines can effectively sew heavy fabrics for furniture and outdoor items.

Moreover, the outdoor and sports industries rely heavily on such machines for products designed to endure harsh elements, such as camping gear, waterproof clothing, and rugged backpacks. The construction industry frequently uses heavy material sewing machines for safety gear and tool bags, ensuring that workers have reliable equipment they can depend on.

Conclusion

In summary, heavy material sewing machines are an essential component of modern textile manufacturing. Their ability to handle tough fabrics with precision and durability makes them indispensable across many industries. As global demand for strong, reliable products continues to rise, investing in high-quality heavy material sewing machines can significantly enhance production efficiency and product quality. Whether for large-scale manufacturing or specialized crafts, these machines represent the backbone of heavy-duty fabric construction, allowing industries to innovate while maintaining the integrity of their products.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025