Heavy-duty Sewing Machines for Industrial Applications and Projects

The Role of Heavy Industrial Sewing Machines in Modern Manufacturing

Heavy industrial sewing machines are essential tools in the textile and manufacturing industries, playing a pivotal role in producing high-quality garments, upholstery, and various other fabric-based products. Unlike their domestic counterparts, these machines are designed to handle thicker fabrics and operate at higher speeds, making them indispensable in factories and production lines where efficiency and durability are key.

One of the primary advantages of heavy industrial sewing machines is their ability to sew through multiple layers of heavy materials such as denim, canvas, leather, and other sturdy textiles. This capability is particularly crucial in industries such as automotive, furniture, and outdoor gear manufacturing, where products must withstand wear and tear over time. For instance, the production of durable outdoor equipment like tents and backpacks requires the use of robust stitching techniques that can only be achieved with industrial machines.

Moreover, heavy industrial sewing machines are equipped with powerful motors and specialized attachments, enabling operators to perform a variety of sewing techniques and tasks. These machines can execute straight stitches, zigzag stitches, and even more complex patterns, allowing companies to create intricate designs that enhance the aesthetic appeal of their products. For example, in apparel manufacturing, decorative stitching can be applied to enhance the visual appeal of clothing items, ensuring they stand out in a competitive market.

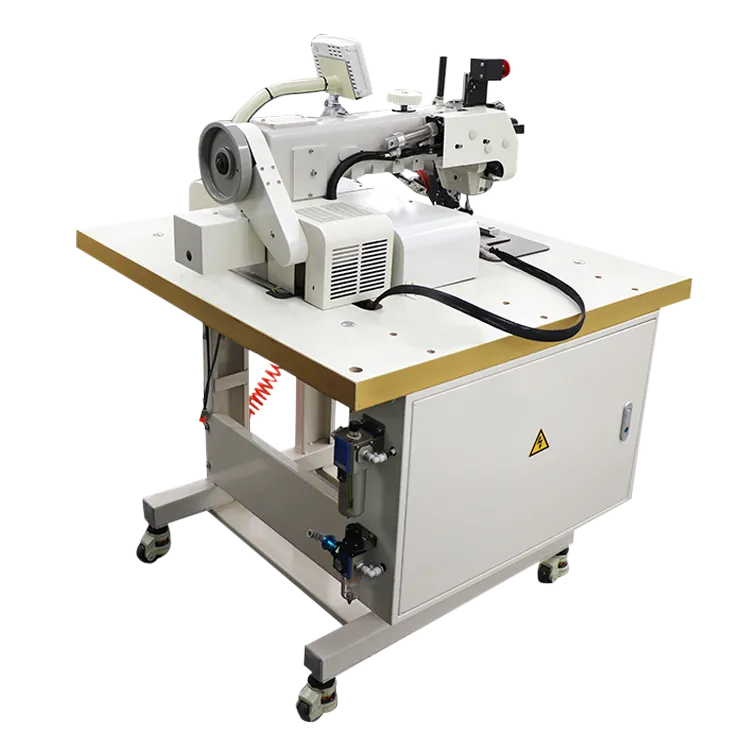

heavy industrial sewing machine

The speed of operation is another significant factor that makes heavy industrial sewing machines vital to manufacturing. With the ability to sew at speeds of up to 5,000 stitches per minute, these machines can drastically reduce production time. This increased efficiency allows manufacturers to meet tight deadlines and respond swiftly to market demands. In today’s fast-paced business environment, the capacity to deliver products quickly can significantly impact a company’s bottom line and customer satisfaction.

Furthermore, advancements in technology have led to the development of computerized heavy industrial sewing machines. These modern machines come equipped with programmable features that allow for precise stitching patterns and adjustments. Automation in sewing not only boosts productivity but also enhances accuracy, reducing the chances of human error. As a result, manufacturers can achieve consistent quality in their products, which is essential for maintaining a strong brand reputation.

However, the investment in heavy industrial sewing machines does require a considerable financial commitment. Businesses must weigh the upfront costs against potential long-term savings and increased productivity. Training staff to operate these machines effectively is also crucial, as skilled operators can maximize the machine’s capabilities and ensure high-quality output.

In conclusion, heavy industrial sewing machines are indispensable in the contemporary manufacturing landscape. Their ability to work with thick materials, combined with high-speed capabilities and advanced technology, empowers businesses to produce durable and attractive products efficiently. As industries continue to evolve, the role of these machines will likely expand, adapting to meet the challenges of modern manufacturing while remaining a cornerstone of textile production. Investing in heavy industrial sewing machines not only enhances operational efficiency but also positions companies for success in a competitive market.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025