Jan . 30, 2025 00:44

Back to list

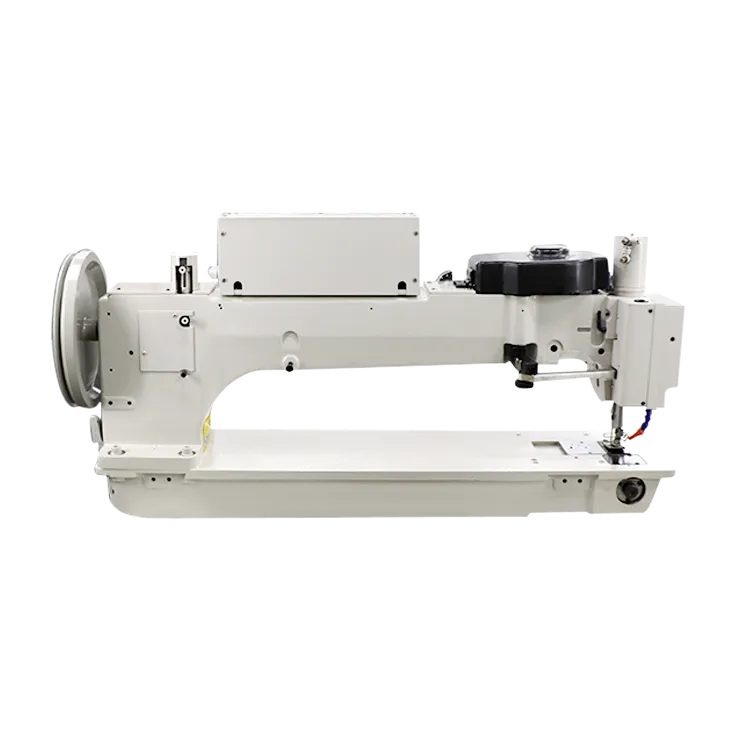

heavy duty industrial sewing machine

Choosing the right heavy-duty industrial sewing machine can significantly impact the efficiency and quality of your sewing projects, especially when dealing with challenging materials such as leather, canvas, and multiple layers of fabric. The market offers a multitude of options, but understanding which machine best suits your specific needs can be daunting. Let's explore the essential aspects of these powerful machines, backed by real-world expertise and experience.

Ease of maintenance is another aspect that can influence decision-making. Industrial machines are designed to withstand high-volume use, yet regular maintenance is essential to prolong their life span. Machines that are easy to service, with readily available parts and comprehensive manuals, score higher in terms of user preference. In addition to operational benefits, purchasing a heavy-duty industrial sewing machine also represents a financial investment. Cost considerations must extend beyond the initial purchase price to include potential repair costs, availability of parts, and energy consumption over time. Investing in a machine with higher upfront costs but better longevity and efficiency can be more economical in the long run. Trustworthiness in the market comes from corroborated reviews and user testimonials. These insights often reveal a machine's long-term performance and reliability better than any specification sheet. Users frequently share their experiences on forums and review sites, detailing the pros and cons they've encountered. This feedback can be instrumental in making an informed decision. Lastly, many companies offer technician support and training sessions for their machines, which are invaluable for new users or those transitioning from standard household machines to industrial-grade equipment. Access to professional training enhances skills and maximizes the machine's potential, ensuring a smoother operational experience. In summary, the choice of a heavy-duty industrial sewing machine should be guided by the specific requirements of your workload, the machine's features, and the overall value it offers. By prioritizing machines from reputable brands with a proven track record, users can rely on their product's performance and support. Carefully evaluating these factors will lead you to a machine that not only meets but exceeds your sewing needs, cementing your position ahead in any competitive craft, garment, or upholstery industry.

Ease of maintenance is another aspect that can influence decision-making. Industrial machines are designed to withstand high-volume use, yet regular maintenance is essential to prolong their life span. Machines that are easy to service, with readily available parts and comprehensive manuals, score higher in terms of user preference. In addition to operational benefits, purchasing a heavy-duty industrial sewing machine also represents a financial investment. Cost considerations must extend beyond the initial purchase price to include potential repair costs, availability of parts, and energy consumption over time. Investing in a machine with higher upfront costs but better longevity and efficiency can be more economical in the long run. Trustworthiness in the market comes from corroborated reviews and user testimonials. These insights often reveal a machine's long-term performance and reliability better than any specification sheet. Users frequently share their experiences on forums and review sites, detailing the pros and cons they've encountered. This feedback can be instrumental in making an informed decision. Lastly, many companies offer technician support and training sessions for their machines, which are invaluable for new users or those transitioning from standard household machines to industrial-grade equipment. Access to professional training enhances skills and maximizes the machine's potential, ensuring a smoother operational experience. In summary, the choice of a heavy-duty industrial sewing machine should be guided by the specific requirements of your workload, the machine's features, and the overall value it offers. By prioritizing machines from reputable brands with a proven track record, users can rely on their product's performance and support. Carefully evaluating these factors will lead you to a machine that not only meets but exceeds your sewing needs, cementing your position ahead in any competitive craft, garment, or upholstery industry.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025