Heavy Duty Bag Production Equipment for Efficient Manufacturing Solutions

The Heavy Duty Bag Making Machine A Game-Changer in Packaging Industry

In the modern world where packaging is pivotal to product protection and marketing, the heavy duty bag making machine has emerged as a revolutionary tool in the manufacturing industry. This sophisticated machine is specifically designed to streamline the production of durable and high-quality bags that can withstand even the most demanding conditions.

What is a Heavy Duty Bag Making Machine?

A heavy duty bag making machine is a specialized piece of equipment used to manufacture various types of bags, including but not limited to, shopping bags, carrier bags, and industrial sacks. Unlike standard bag-making machines that cater to lightweight materials, heavy duty variations are built to handle robust materials such as woven polypropylene, multi-layered fabrics, and other heavy-duty plastics. This capability makes them essential for businesses requiring strong and durable packaging solutions.

Key Features

One of the defining features of heavy duty bag making machines is their advanced construction. These machines are equipped with powerful motors and high-quality components that allow for faster production speeds and consistent output. They incorporate technologies such as automatic feeding systems, electronic tension control, and programmable logic controllers (PLCs) to ensure precision and efficiency. Moreover, many models offer versatility, enabling manufacturers to produce bags in various sizes, shapes, and styles, catering to diverse market needs.

Benefits to Manufacturers

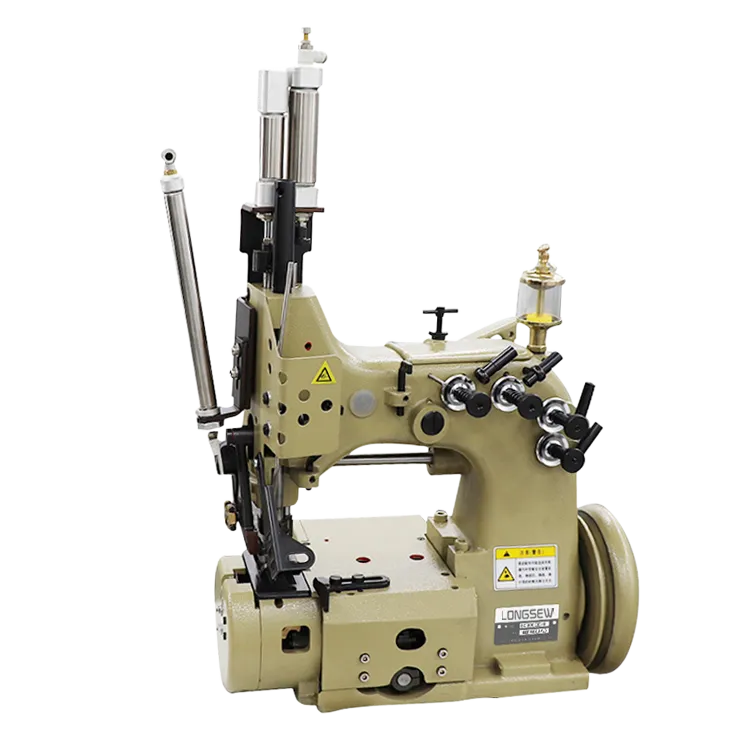

heavy duty bag making machine

The integration of heavy duty bag making machines into manufacturing processes offers several benefits. Firstly, they significantly reduce labor costs as these machines can operate autonomously, requiring minimal human intervention. This automation not only increases production rates but also enhances accuracy, reducing waste and errors that are common in manual processes.

Secondly, the durability of the bags produced using these machines contributes to cost savings over time. Heavy-duty bags typically have a longer life span compared to their lightweight counterparts, reducing the frequency of replacements and minimizing the overall expenditure for businesses using them for packaging.

Additionally, with growing environmental concerns, many modern heavy duty bag making machines are designed to be eco-friendly. They can work with biodegradable materials and recyclable plastics, aligning with sustainable practices that are increasingly important to consumers and regulatory bodies alike.

The Market Demand

The demand for heavy duty bag making machines has surged in recent years, driven by the expansion of e-commerce and the packaging industry. As consumers increasingly shift towards online shopping, the need for robust packaging solutions is more pressing than ever. Businesses are looking for reliable, cost-effective methods to package their products safely, and heavy duty bags have become a preferred choice due to their strength and reliability.

Conclusion

In conclusion, the heavy duty bag making machine is a vital asset for any manufacturer looking to enhance their production capabilities and meet the growing demands of the packaging industry. Its advanced features boost efficiency, reduce costs, and support sustainable practices. As the market for durable packaging continues to expand, investing in a heavy duty bag making machine is not just a smart business move; it's an essential step toward future-proofing operations in a competitive landscape. The evolution of this technology will undoubtedly shape the future of bag manufacturing, making it a cornerstone in the quest for quality and sustainability in packaging solutions.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025