heavy duty stitching service

Heavy Duty Stitching Services Ensuring Durability and Strength

In industries where durability and resilience are paramount, heavy duty stitching services have emerged as a vital component in the production process. From outdoor gear to automotive upholstery, heavy duty stitching provides the strength needed to withstand strenuous conditions and heavy use. This article delves into the intricacies of heavy duty stitching, its applications, and the benefits it offers.

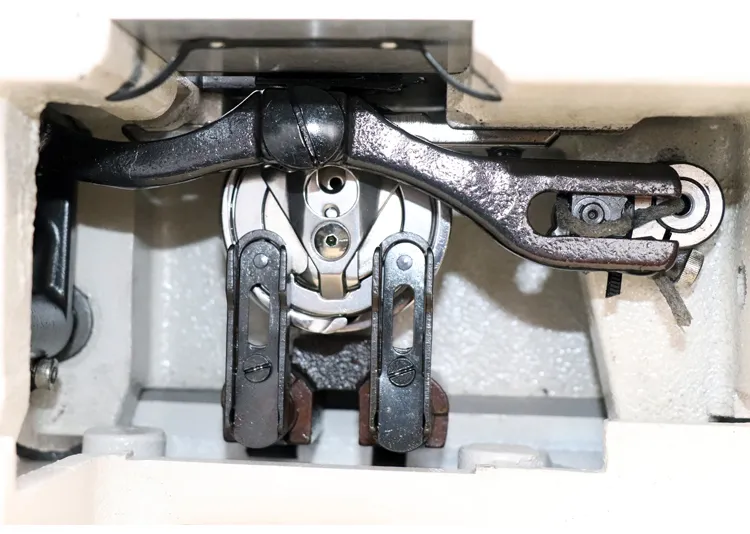

Heavy duty stitching refers to the use of specialized sewing techniques and strong materials to create robust seams capable of enduring significant stress and wear. Traditional stitching may suffice for light fabrics, but when it comes to heavy materials like canvas, leather, or multiple layers, standard stitching techniques often fall short. Heavy duty stitching is designed to tackle these challenges, ensuring that the seams remain intact throughout the life of the product.

One of the primary applications of heavy duty stitching is in the manufacturing of outdoor gear, such as tents, backpacks, and protective clothing. These products are often exposed to harsh weather conditions, rugged terrains, and frequent handling. Heavy duty stitching not only enhances the overall durability of these items but also ensures that they can withstand extreme conditions without succumbing to wear and tear. In industries such as construction and firefighting, heavy duty stitching is critical in creating uniforms and gear that need to meet high safety standards.

heavy duty stitching service

Moreover, heavy duty stitching is equally important in the automotive sector. Whether it’s the upholstery of a car interior or the construction of heavy-duty floor mats, the stitching must be able to endure constant friction and weight. By utilizing industrial sewing machines and strong threads, manufacturers can produce automotive products that not only provide comfort and style but also maintain structural integrity under pressure.

The benefits of heavy duty stitching extend beyond mere durability. First and foremost, it enhances the aesthetic appeal of the products. Well-executed heavy duty stitching can add a professional finish, giving items a polished and high-quality appearance. Additionally, the precision involved in heavy duty stitching allows for more intricate designs and patterns, appealing to consumer preferences for customization.

Another significant advantage is the reduction in product returns. Products that feature strong heavy-duty seams have a lower likelihood of ripping or tearing, leading to higher customer satisfaction and repeat business. In industries where reputation and reliability are crucial, the importance of choosing heavy duty stitching cannot be overstated.

In conclusion, heavy duty stitching services play a crucial role in various industries, providing the necessary strength and durability required for high-performance products. Whether in outdoor gear, automotive applications, or other demanding environments, the benefits of investing in heavy duty stitching are undeniable. As businesses continue to prioritize quality and durability, heavy duty stitching will remain an essential service in the production of long-lasting products.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025