Heavy Duty Sewing Machines: Auto & Walking Foot Industrial Models

The Crucial Role of Heavy-Duty Sewing Machines in Modern Industry

In today's industrial landscape, where precision and durability are paramount, the demand for robust and reliable machinery has never been higher. Among these essential tools, the heavy duty sewing machine stands out as a cornerstone for manufacturing industries that handle thick, multi-layered, or challenging materials. From automotive upholstery to marine canvas, and critically, in the production of Flexible Intermediate Bulk Containers (FIBCs), these specialized machines deliver the strength and consistency required to ensure product integrity and operational safety. Current market trends indicate a significant growth in sectors relying on such robust stitching capabilities, driven by increasing global trade and stringent packaging standards for bulk goods. This segment of industrial machinery is continuously evolving, incorporating advanced automation and material handling solutions to meet the escalating demands of high-volume production.

The market for heavy duty sewing machine technology is projected to expand significantly, fueled by innovations in material science and an increasing emphasis on sustainable, reusable packaging solutions. Manufacturers are seeking machines that not only provide superior stitch strength but also offer enhanced energy efficiency and reduced maintenance requirements. The integration of advanced motor technologies, such as servo motors, contributes to precise speed control and lower energy consumption, addressing both performance and environmental concerns. Furthermore, the ability to handle a diverse range of thread sizes and material thicknesses is becoming a standard expectation, enabling greater versatility across different applications. This evolution underscores the critical need for machines capable of enduring continuous, rigorous operation while maintaining optimal performance.

Technical Deep Dive: Unpacking Key Parameters

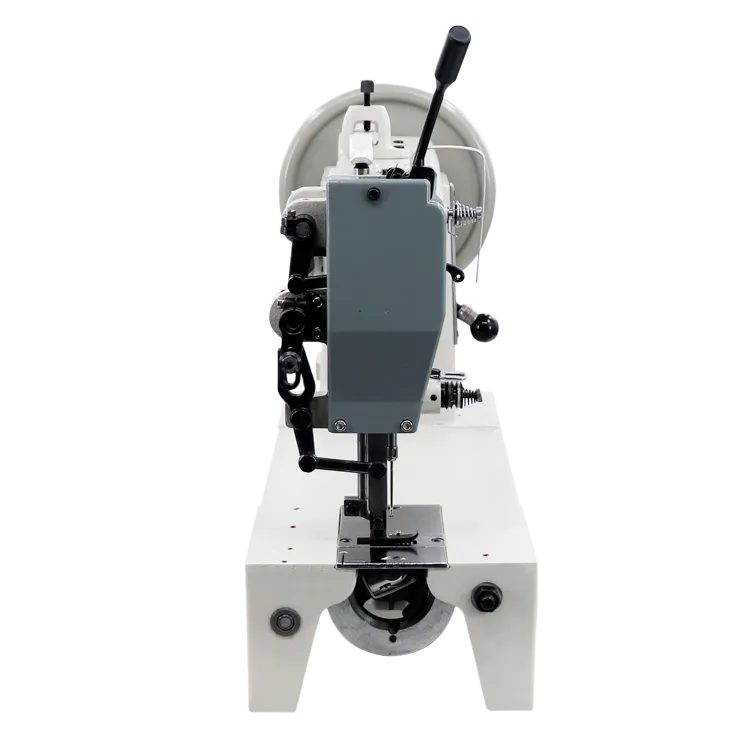

Understanding the core technical specifications is vital for selecting the appropriate heavy duty sewing machine for specific industrial applications. Parameters such as maximum sewing speed, stitch length, presser foot lift, and needle system dictate the machine's efficiency and material compatibility. For instance, the FIBC Bag Heavy Duty Single Needle Lock Stitch Top & Bottom Feeding Flat Bed Sewing Machine LS7800/LS7800TD, designed specifically for heavy-duty materials like those used in FIBC bags, exemplifies a machine built for robustness. Its top and bottom feeding mechanism ensures uniform material handling, preventing slippage and ensuring consistent stitch quality even on multi-layered fabrics. The maximum stitch length is crucial for creating strong, secure seams, while the powerful motor ensures consistent penetration through dense materials without compromising speed or efficiency.

Key Specifications Comparison: LS7800/LS7800TD vs. Generic Heavy-Duty Model

| Parameter | LS7800/LS7800TD (Example) | Generic Heavy-Duty Model (Avg.) |

|---|---|---|

| Max. Sewing Speed | 1800-2000 Stitches/min | 1200-1500 Stitches/min |

| Max. Stitch Length | 12mm (0.47 inches) | 9mm (0.35 inches) |

| Presser Foot Lift (by Hand/Knee) | 10mm / 16mm | 8mm / 13mm |

| Needle System | DPx17 (Sizes 23-27) | DPx17 (Sizes 22-26) |

| Thread Sizes Supported | V92 to V415 (Tex 90 to Tex 400) | V92 to V346 (Tex 90 to Tex 350) |

| Lubrication System | Automatic Full-Open Oil Pump | Manual/Semi-Automatic |

| Motor Type (LS7800TD) | Integrated Servo Motor | Clutch Motor (common) |

The LS7800/LS7800TD's superior presser foot lift and robust needle system (DPx17) accommodate thicker materials and larger threads, essential for reliable stitching on industrial fabrics. Furthermore, the option of an integrated servo motor (TD model) transforms it into an auto heavy duty sewing machine, offering precise speed control, quiet operation, and significant energy savings compared to traditional clutch motors. This technical superiority translates directly into higher productivity, reduced material waste, and extended machine lifespan in demanding production environments.

Precision Engineering: The Manufacturing Process and Quality Assurance

The durability and performance of a heavy duty sewing machine are intrinsically linked to its manufacturing process and the quality of its components. High-grade materials are meticulously selected, including specialized alloys for gears and shafts, and robust cast iron or aluminum for machine frames, ensuring structural integrity and vibration dampening. Critical components often undergo processes such as precision CNC machining, ensuring tight tolerances and seamless integration. For instance, the robust construction of a heavy duty sewing machine motor is crucial for consistent power delivery, especially when penetrating multiple layers of dense fabric.

Quality control is paramount throughout the entire manufacturing workflow. Reputable manufacturers adhere to stringent international standards such as ISO 9001 for quality management systems and ANSI standards for specific mechanical components. Each machine undergoes rigorous testing, including endurance tests simulating years of operation, material penetration tests with various thicknesses, and precision alignment checks. This meticulous process ensures minimal downtime, extended service life, and consistent high-quality output. The emphasis on robust engineering and strict inspection standards significantly enhances the lifespan of these machines, often exceeding a decade even under continuous industrial use. This commitment to quality translates into long-term cost savings and enhanced operational reliability for businesses.

Diverse Applications and Unmatched Advantages

The versatility of a heavy duty sewing machine extends across a myriad of industrial applications where robust stitching is non-negotiable. Beyond FIBC bag production, these machines are indispensable in industries such as automotive (car seats, airbags), marine (sails, boat covers), outdoor gear (tents, backpacks), saddlery, and protective clothing manufacturing. The primary advantage of a heavy duty walking foot sewing machine, for example, is its compound feeding mechanism, where the needle, presser foot, and feed dog move in unison, preventing material puckering and ensuring perfectly aligned stitches on challenging materials. This feature is critical for maintaining seam strength and aesthetic quality on multi-layered or slippery fabrics.

In application scenarios like FIBC manufacturing, which is crucial for industries ranging from petrochemicals and agriculture to construction and mining, the reliability of the stitching directly impacts safety and transport efficiency. A well-engineered heavy duty sewing machine offers unparalleled advantages: enhanced productivity due to higher speeds and less material handling issues, superior seam strength reducing product leakage or damage, and significant cost savings through reduced material waste and improved operational longevity. The ability to handle extremely thick threads and multi-ply materials without breaking needles or threads significantly boosts production efficiency and ensures compliance with critical industry standards for bulk material handling.

Choosing Your Partner: Manufacturer Comparison and Custom Solutions

When investing in a heavy duty sewing machine, the choice of manufacturer is as critical as the machine's specifications. Leading manufacturers distinguish themselves not just by product quality but also by their R&D capabilities, after-sales support, and ability to provide customized solutions. While searching for "cheap heavy duty sewing machine" might offer initial savings, it often overlooks the long-term total cost of ownership, including maintenance, spare parts availability, and potential production downtime. Reputable manufacturers like LONGSEW, with decades of experience, offer a proven track record of durability, performance, and dedicated customer service. They ensure that their machines, such as the LS7800/LS7800TD, are not only built to last but are also supported by comprehensive technical assistance and readily available genuine parts.

For specialized industrial needs, standard models may not suffice. Custom solutions, tailored to unique material handling challenges or production line integrations, are a key differentiator. This might involve modifications to the work area, specific automation features, or integration with existing material feeding systems. Discussing your specific requirements with manufacturers can lead to optimized solutions that maximize efficiency and output. Understanding heavy duty sewing machine prices involves not just the initial purchase cost but also evaluating the machine's long-term value, including its energy efficiency, maintenance costs, and projected lifespan. A trusted manufacturer will provide transparent pricing models, detailed quotes, and a clear understanding of the return on investment.

Ensuring Trust and Support: FAQs, Warranty, and Customer Service

Building trust with industrial clients goes beyond just providing a high-quality heavy duty sewing machine; it encompasses transparent service, robust support, and clear commitments. Manufacturers like LONGSEW prioritize customer satisfaction through comprehensive support systems, including detailed documentation, expert technical assistance, and a readily available supply of spare parts. Understanding the delivery schedules and post-purchase support is crucial for seamless integration into your production workflow. Long-term partnerships are built on reliability, and knowing that your investment is protected by a solid warranty and accessible service team provides invaluable peace of mind.

Frequently Asked Questions (FAQs)

-

Q: What is the typical lifespan of a heavy-duty industrial sewing machine?

A: With proper maintenance and consistent usage, a high-quality industrial heavy-duty sewing machine can last 10-20 years or even longer. Key factors include regular lubrication, timely replacement of worn parts, and adherence to manufacturer guidelines. -

Q: How does a walking foot mechanism enhance sewing performance on heavy materials?

A: A walking foot system, often found on a heavy duty walking foot sewing machine, simultaneously moves the upper and lower layers of fabric with the needle and feed dogs. This synchronized movement eliminates slippage, ensuring even feeding and consistent stitch length on thick, layered, or challenging materials like canvas, leather, or multiple plies of webbing. -

Q: What kind of warranty and after-sales support can I expect?

A: Most reputable manufacturers offer a standard 1-year warranty on mechanical and electrical components. Beyond this, comprehensive after-sales support typically includes technical consultation, access to genuine spare parts, maintenance guides, and, in some cases, on-site service or virtual troubleshooting. Delivery schedules are usually communicated transparently at the time of order confirmation, often ranging from 4-8 weeks depending on customization.

Authoritative References

- ISO 9001:2015 Quality Management Systems – Requirements, International Organization for Standardization.

- Textile World Magazine, "Innovations in Technical Textiles and Industrial Sewing," various issues.

- Journal of Manufacturing Processes, "Advanced Fabrication Techniques for Industrial Machinery," Vol. X, Issue Y.

- American National Standards Institute (ANSI) - Relevant standards for mechanical engineering and safety.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025