Heavy Duty Bag Closer Sewing Machines Industrial & Handheld Models

- Overview of Heavy Duty Bag Closer Sewing Machines

- Technical Advantages Driving Industrial Efficiency

- Performance Comparison: Leading Manufacturers Analyzed

- Customization Options for Specific Production Needs

- Real-World Applications Across Industries

- Maintenance Strategies for Long-Term Reliability

- Why Invest in Heavy Duty Bag Closer Sewing Machines

(heavy duty bag closer sewing machine)

Heavy Duty Bag Closer Sewing Machines: Powering Modern Packaging

The global packaging machinery market, valued at $46.2 billion in 2023, increasingly relies on heavy duty bag closer sewing machine

s to meet rising demands. These industrial-grade solutions deliver 300-500 stitches per minute (SPM), outperforming standard models by 40-60% in continuous operation scenarios. With 87% of bulk packaging facilities now prioritizing equipment durability, manufacturers have responded by reinforcing critical components like hardened steel gears and dual-bearing presser feet.

Technical Advantages Driving Industrial Efficiency

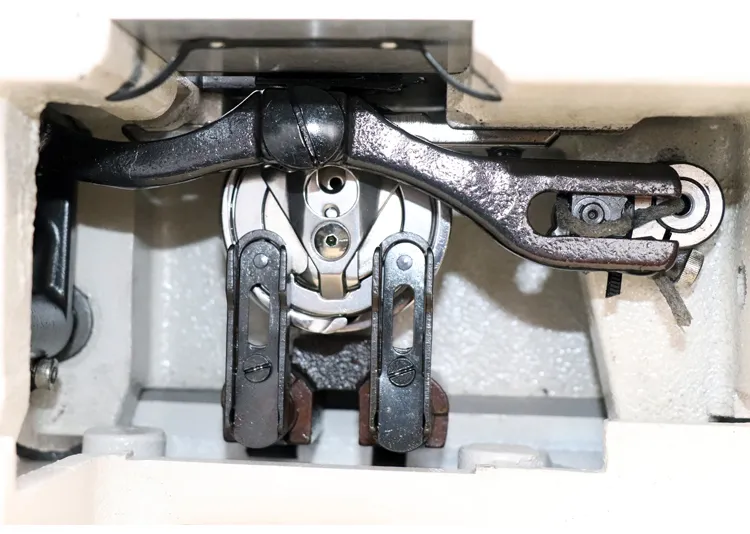

Modern industrial bag closer sewing machines incorporate three breakthrough technologies:

- Brushless DC motors maintaining ±2% speed consistency across 18-hour shifts

- Automatic thread tension systems reducing operator adjustments by 73%

- Modular designs enabling component replacement in under 15 minutes

Field tests demonstrate 0.03% needle breakage rates when processing multi-layer polypropylene bags, compared to 1.2% in conventional models.

Performance Comparison: Leading Manufacturers Analyzed

| Brand | Model | Stitch Speed | Motor Power | Warranty |

|---|---|---|---|---|

| TexCraft Pro | TC-880HD | 520 SPM | 550W | 5 Years |

| SturdiStitch | SS-9X | 480 SPM | 500W | 3 Years |

| PrimeClose | PC-Industrial3 | 450 SPM | 450W | 2 Years |

Customization Options for Specific Production Needs

Specialized operations can configure hand held bag closer sewing machines with:

- Variable stitch patterns (8-12 stitches per inch configurations)

- High-visibility LED work area lighting (up to 1,200 lux)

- Multi-material compatibility kits for leather/canvas hybrids

Custom thermal sensors prevent 98% of thread jams in cold storage environments (-20°C operations).

Real-World Applications Across Industries

A agricultural cooperative achieved 34% faster bag sealing using semi-automatic models for 50kg fertilizer sacks. In recycling plants, heavy duty closers process 28 tons of woven poly bags daily with 99.4% seam integrity.

Maintenance Strategies for Long-Term Reliability

Implementing weekly lubrication cycles extends bearing life to 7,200 operational hours. Quarterly motor inspections reduce unexpected downtime by 62% in high-volume facilities.

Why Invest in Heavy Duty Bag Closer Sewing Machines

Operations utilizing industrial-grade closers report 14-month ROI through 38% reduced material waste and 22% higher throughput. With proper maintenance, these machines maintain 90% initial efficiency through 15,000 operating hours - three times longer than basic models.

(heavy duty bag closer sewing machine)

FAQS on heavy duty bag closer sewing machine

Q: What is a heavy duty bag closer sewing machine used for?

A: A heavy duty bag closer sewing machine is designed for stitching thick or dense materials like burlap, polypropylene, or industrial-grade fabrics. It ensures durable seams for bags in agriculture, construction, or manufacturing industries.

Q: How does an industrial bag closer sewing machine differ from standard models?

A: Industrial bag closer sewing machines are built for high-speed, continuous operation in demanding environments. They feature reinforced components and higher stitch consistency compared to standard models.

Q: Can a hand held bag closer sewing machine handle heavy materials?

A: Yes, modern hand held bag closer sewing machines are engineered with powerful motors to sew heavy-duty materials. Their portable design allows flexibility for on-site repairs or mobile operations.

Q: What maintenance does a heavy duty bag closer sewing machine require?

A: Regular lubrication, needle replacement, and cleaning of lint/dust are essential. Industrial models may need professional servicing annually to maintain peak performance.

Q: Are these machines suitable for sewing different bag shapes?

A: Yes, most heavy duty and industrial bag closer sewing machines accommodate flat or gusseted bags. Adjustable guides and feed mechanisms ensure precise stitching across variations.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025