Harnessing the Power of Sewing Machines for Creative Projects and Efficient Crafting

Harness Sewing Machines A Key Tool in the Manufacturing of Durable Goods

The evolution of sewing machines has transformed many industries, and among the various specialized sewing machines available, the harness sewing machine holds a unique and vital place. These machines are specifically designed for sewing heavy materials such as leather, which is commonly used in producing harnesses for horses, saddles, and various types of protective gear. This article will explore the importance of harness sewing machines, their functionality, and their impact on craftsmanship and efficiency in manufacturing.

The Importance of Harness Sewing Machines

Harness sewing machines are integral to the production of high-quality, durable goods. They provide a level of precision and strength necessary for stitching thick materials that would be unsuitable for standard sewing machines. The demand for durable leather products has continued to rise, especially in industries such as agriculture, equestrian sports, and outdoor recreation. As a result, the need for reliable machinery that can handle the unique challenges posed by heavy materials has increased dramatically.

Moreover, these machines are often specifically designed to accommodate the intricate designs and structures involved in crafting harnesses. The robustness of their construction ensures that they can withstand the rigors of continuous operation, making them an essential investment for small workshops and large-scale manufacturing facilities alike.

Functionality and Features

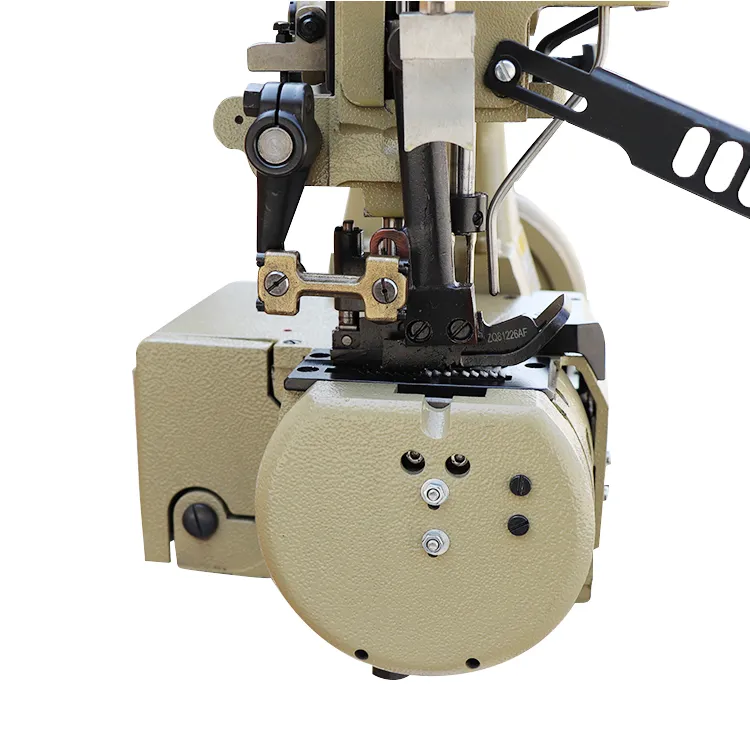

Harness sewing machines typically boast features that cater specifically to the needs of heavy-duty sewing. Many are built with heavy frames to support the additional weight of the materials used. These machines often employ walking feet or compound feed mechanisms that allow the operator to efficiently manage multiple layers of thick fabric or leather. This design helps prevent slippage and ensures even stitching throughout the length of the seam.

harness sewing machine

Additionally, harness sewing machines typically have a higher stitch per minute (SPM) rate compared to regular machines. This enhanced speed facilitates faster production without sacrificing quality. Features like adjustable stitch length and tension control further enhance their functionality, enabling users to tailor stitches according to specific project requirements.

Many modern harness sewing machines also incorporate computerized technology, allowing for programmable stitching patterns. This feature can significantly enhance productivity by automating certain tasks, thus reducing labor intensity and minimizing the risk of human error.

Impact on Craftsmanship and Efficiency

The introduction of harness sewing machines has revolutionized the craftsmanship involved in producing leather goods. Skilled artisans can now harness the power of these machines to create intricate designs and precise cuts, something that was more cumbersome and time-consuming in the past. The combination of traditional techniques and modern machinery has revitalized the industries that rely on these high-quality products.

In terms of efficiency, the use of harness sewing machines has transformed production timelines. What once took days or weeks can now often be completed in a matter of hours, allowing businesses to meet market demands swiftly. Furthermore, the durability of machine-sewn products ensures that consumers receive high-quality items that stand the test of time, fostering greater customer satisfaction and brand loyalty.

Conclusion

Harness sewing machines represent a critical advancement in the world of textile and leather production. Their specialized design allows for the efficient and precise sewing of heavy materials, catering to the growing demand for durable goods. As manufacturing continues to embrace technology, the integration of modern features into traditional sewing practices ensures that craftsmanship remains alive and well in the industry. For anyone involved in the production of harnesses, saddles, or any heavy-duty leather goods, investing in a quality harness sewing machine is not just a business decision but a step toward ensuring the longevity and excellence of their products. As the industry evolves, these machines will undoubtedly continue to play an essential role in shaping the future of durable goods manufacturing.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025