Sewing Machines for Harness Making and Repairing Techniques and Tips

Harness Sewing Machine A Vital Tool in the Textile Industry

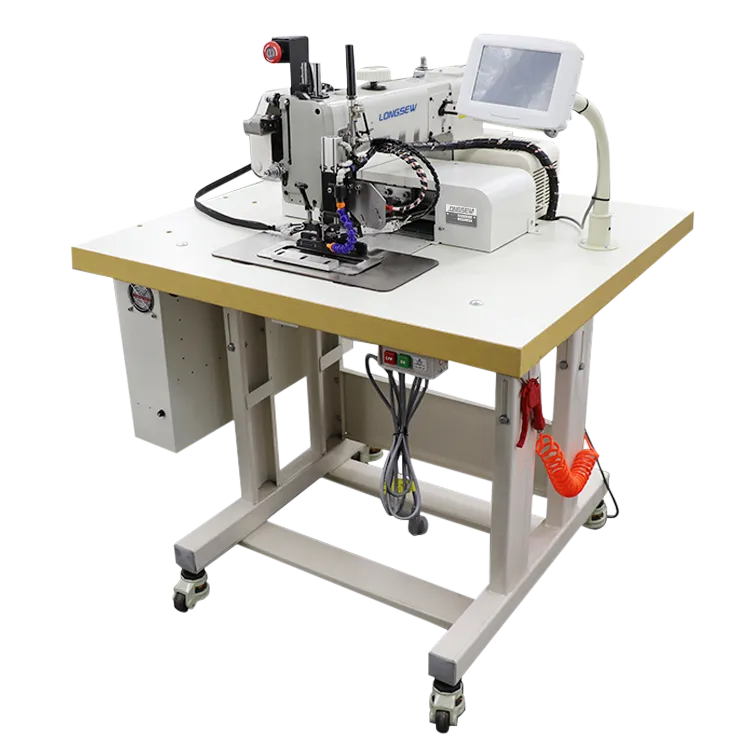

The harness sewing machine plays a crucial role in the textile industry, particularly in the production of harnesses and other heavy-duty materials

. These specialized machines are designed to stitch together tough fabrics like leather, canvas, and synthetic materials, making them indispensable for manufacturers of harnesses used in various applications, such as automotive, saddlery, and industrial purposes.One of the primary advantages of harness sewing machines is their ability to handle thick and heavy materials that standard sewing machines cannot accommodate. This strength comes from their robust construction and powerful motor capabilities, which allow for consistent sewing without skipping stitches or damaging the fabric. These machines typically feature a walking foot mechanism that ensures even feeding of materials through the machine, reducing the risk of material slippage and misalignment that can lead to poor-quality seams.

In addition to their strength and durability, harness sewing machines are equipped with specialized features that enhance their functionality. Many models come with adjustable stitch length and width settings, allowing users to customize their stitches according to the specific demands of each project. This adaptability is crucial for manufacturers who produce a variety of harnesses for different uses, as the stitching requirements can differ significantly based on the load-bearing needs and design specifications of the harness.

Another beneficial aspect of harness sewing machines is their versatility. Although they are primarily designed for stitching harnesses, these machines can also be utilized for sewing other heavy-duty items such as bags, outdoor gear, and upholstery. This multipurpose functionality makes them a wise investment for businesses that require a reliable and efficient sewing solution across different product lines.

harness sewing machine

The operation of a harness sewing machine is not without its challenges. The thickness of the materials often requires experienced operators who possess a deep understanding of the machine's capabilities. Proper threading, tension adjustments, and maintenance are crucial to ensure optimal performance. Neglecting these aspects can lead to operational difficulties, including thread breakage, uneven stitching, and increased wear and tear on the machine.

Furthermore, the technology in harness sewing machines has seen significant advancements in recent years. Modern machines incorporate digital controls, automated functions, and enhanced safety features that streamline the sewing process. For example, some machines are now equipped with programmable settings, which allow users to save specific stitch patterns for repeated use, thereby increasing efficiency in production.

As the demand for high-quality, durable harnesses continues to grow, the importance of harness sewing machines in the industry becomes ever more apparent. Manufacturers are consistently looking for ways to optimize their production processes and improve product quality, making investing in advanced sewing technology crucial for staying competitive.

In summary, the harness sewing machine stands as a testament to the evolution of sewing technology within the textile industry. Its strength, versatility, and adaptability make it an essential tool for producing high-quality harnesses and heavy-duty textiles. As industries continue to innovate and expand, the harness sewing machine will undoubtedly remain at the forefront of production, helping manufacturers meet the rising demands for reliable and durable products. By investing in the right harness sewing machines and skilled operators, businesses can ensure that they are well-equipped to tackle the challenges of modern manufacturing and maintain high standards in their offerings.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025