Harnessing Creativity with Innovative Sewing Machine Techniques for Every Crafter

The Evolution and Significance of the Harness Sewing Machine

In the world of textile manufacturing and garment creation, the harness sewing machine stands out as a pivotal innovation that transformed the industry. These machines were engineered specifically for harness making, catering to the needs of equestrian and agricultural sectors. As we delve into the evolution and significance of the harness sewing machine, we will explore its history, its technological advancements, and its impact on modern manufacturing.

Historical Background

The roots of the harness sewing machine can be traced back to the early 19th century when manual sewing techniques were the norm. Craftsmen meticulously stitched harnesses by hand, a process that was not only labor-intensive but also time-consuming. As the demand for harnesses grew, especially with the rise of horse-drawn carriages and agricultural practices, there was an urgent need for more efficient production methods.

The invention of powered sewing machines in the mid-19th century marked a revolutionary turning point. While machines like the Singer sewing machine were designed for lighter fabric work, the harness sewing machine was robustly built to handle heavier materials such as leather, canvas, and other durable textiles. This specialization allowed for quicker production times and improved consistency in quality.

Technological Advancements

Over the years, the harness sewing machine underwent significant technological advancements. Early models operated on a simple mechanical principle, using a single needle and thread to stitch heavy materials. However, as manufacturing processes evolved, so did the technology behind these machines. Modern harness sewing machines now incorporate advanced features such as

1. Multiple Needles Used for various stitching techniques, enabling complex designs and stronger seams.

2. Computerization With the introduction of computerized models, manufacturers gained the ability to program specific stitch patterns, enhancing customization and precision.

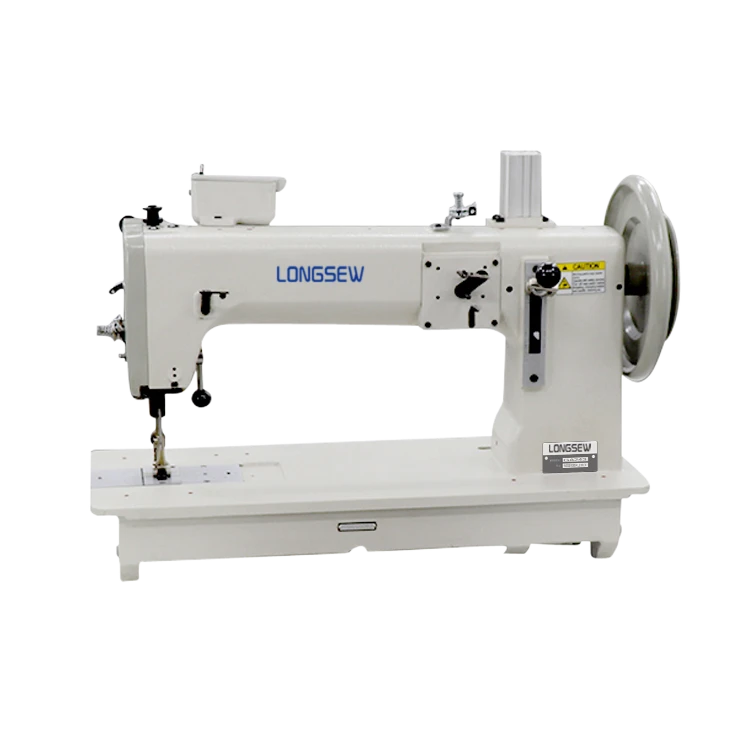

harness sewing machine

3. Heavy-Duty Motors These motors allow machines to work continuously without overheating, making it feasible for big production runs.

4. Automatic Feed Systems Such systems ensure consistent material feeding, reducing errors and increasing efficiency in production.

These advancements not only improved the efficiency of harness production but also expanded the range of products that could be manufactured, from traditional equestrian gear to innovative accessories for various outdoor activities.

Economic and Cultural Impact

The advent of the harness sewing machine had profound economic implications. It significantly lowered production costs and time, which in turn made harnesses more affordable and accessible. This accessibility contributed to the growth of equestrian sports and leisure activities, as more people could own horses and engage in riding.

Culturally, the harness sewing machine represents the intersection of craftsmanship and industrialization. While it streamlined production, it also necessitated a skill set that combined traditional tailoring with machine operation, creating new job opportunities in the manufacturing sector. Craftsmanship evolved to include both manual and machine techniques, ensuring that artisans could adapt to new technologies while retaining traditional skills.

Conclusion

The harness sewing machine exemplifies the relationship between innovation and industry needs. From its humble beginnings in the 19th century to today’s high-tech models, it has played a crucial role in shaping the harness-making industry. Not only has it revolutionized production processes, but it also continues to influence economic growth and cultural practices in the equestrian world. As technology advances further, we can expect future innovations to build upon the legacy of the harness sewing machine, ensuring that it remains a vital part of the textile industry for years to come.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025