Feb . 12, 2025 10:12

Back to list

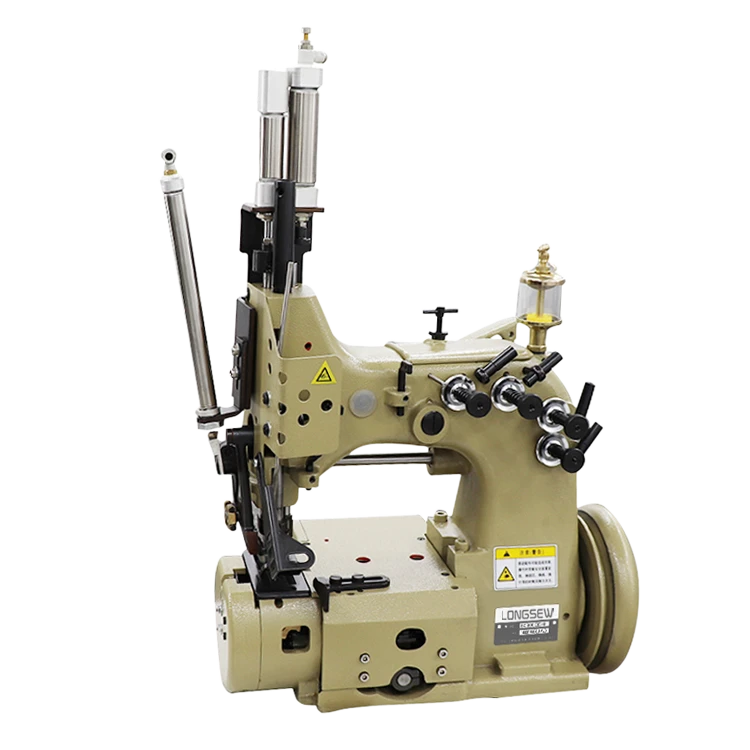

leather cylinder arm sewing machine

Selecting the right leather sewing machine is an essential step for anyone dealing in harness leather or similar heavyweight materials. With decades of experience in leatherworking, I can confidently guide you through the maze of options and considerations involved.

Trustworthiness of the machine can often be gauged by reviews from seasoned leatherworkers. Online communities are brimming with testimonials which provide a candid look into a machine's real-world performance. Look for feedback concerning durability over time, ease of maintenance, and customer service response from manufacturers. Do not overlook the accessory frontier. Presser foot accessories offering specialized functionalities like edge guides are invaluable for precision work required in harness making. Compatibility with additional tools like a dedicated leather puncher or skivers could considerably enhance your workflow efficiency. From a practical viewpoint, setting up your workspace ergonomically can also improve output and comfort during extended periods of work. Consider an adjustable table height and anti-fatigue mats. In conclusion, experience and expertise should guide your selection of a harness leather sewing machine. Whether you are a novice or a seasoned artisan, always prioritize machines from reputable brands that offer specialized heavy-duty features. Seek out those with favorable reviews that emphasize durability and efficiency. Proper setup and accessory integration complete the system, ensuring a productive and rewarding leatherworking experience.

Trustworthiness of the machine can often be gauged by reviews from seasoned leatherworkers. Online communities are brimming with testimonials which provide a candid look into a machine's real-world performance. Look for feedback concerning durability over time, ease of maintenance, and customer service response from manufacturers. Do not overlook the accessory frontier. Presser foot accessories offering specialized functionalities like edge guides are invaluable for precision work required in harness making. Compatibility with additional tools like a dedicated leather puncher or skivers could considerably enhance your workflow efficiency. From a practical viewpoint, setting up your workspace ergonomically can also improve output and comfort during extended periods of work. Consider an adjustable table height and anti-fatigue mats. In conclusion, experience and expertise should guide your selection of a harness leather sewing machine. Whether you are a novice or a seasoned artisan, always prioritize machines from reputable brands that offer specialized heavy-duty features. Seek out those with favorable reviews that emphasize durability and efficiency. Proper setup and accessory integration complete the system, ensuring a productive and rewarding leatherworking experience.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025