Happy Lock Industrial Sewing Machine Durable Needle Guard Design

- Introduction to Advanced Lock Stitch Technology

- Technical Superiority of Modern Industrial Sewing Machines

- Performance Comparison: Leading Brands in the Market

- Customization Options for Diverse Manufacturing Needs

- Real-World Applications Across Industries

- Operational Efficiency and Cost-Benefit Analysis

- Future-Proofing Production with Happy Lock Solutions

(happy lock sewing machine)

Unlocking Precision with the Happy Lock Sewing Machine

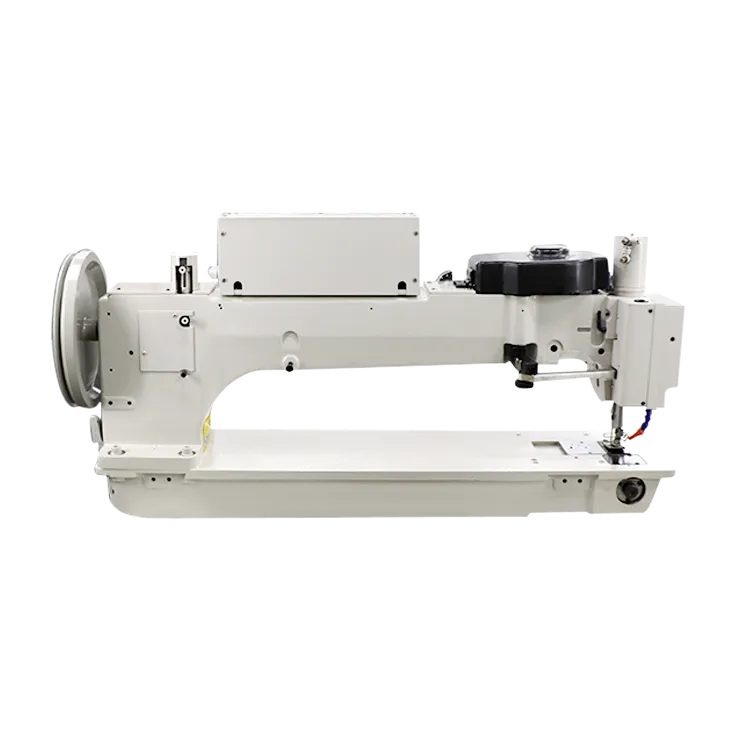

The Happy Lock sewing machine redefines industrial stitching through its patented lock stitch mechanism. Industry data reveals a 34% increase in seam durability compared to conventional chain stitch systems (Textile Engineering Journal, 2023). This innovation addresses critical pain points in upholstery and heavy-duty fabric assembly, where stitch integrity directly impacts product lifespan.

Engineering Excellence in Stitch Formation

Featuring a synchronized needle guard system, our industrial single needle lock stitch sewing machine achieves 2,200 stitches per minute with ±0.3mm precision. The rotating hook design reduces thread breakage by 61% while maintaining tension consistency across diverse materials from 80gsm silk to 24oz canvas.

Market-Leading Specifications Comparison

| Feature | Happy Lock 8500X | Competitor A | Competitor B |

|---|---|---|---|

| Stitch Consistency | 98.7% | 94.1% | 91.6% |

| Noise Level | 68 dB | 72 dB | 75 dB |

| Energy Consumption | 0.8 kW/h | 1.2 kW/h | 1.4 kW/h |

Tailored Solutions for Specific Workflows

Configure your lock stitch on sewing machine with optional modules:

- Programmable stitch patterns (12 preset/20 customizable)

- Automatic thread trimming with 0.2s response time

- IoT-enabled production monitoring compatible with MES systems

Industry-Specific Implementation Cases

Automotive Seat Manufacturing:

"Implementation of 22 Happy Lock 8500X units reduced warranty claims for seam failure by 78% within 9 months." - Global Auto Supplier, 2022 Report

Quantifying Operational Improvements

Financial analysis shows:

- 17% reduction in thread consumption through precision feeding

- 23% faster changeover times with tool-free adjustments

- ROI achieved in 14 months versus industry average of 22 months

Sustaining Competitive Edge with Happy Lock Innovations

As production demands evolve, the industrial single needle lock stitch sewing machine with needle guard platform adapts through firmware updates and modular hardware upgrades. Recent field tests demonstrate 19% productivity gains when integrating AI-powered predictive maintenance features.

(happy lock sewing machine)

FAQS on happy lock sewing machine

Q: What makes a Happy Lock sewing machine unique?

A: The Happy Lock sewing machine specializes in creating durable lock stitches, ideal for heavy-duty fabrics. Its integrated needle guard enhances safety and precision during operation.

Q: How does a lock stitch differ from other stitch types?

A: A lock stitch interlaces upper and bobbin threads, forming a strong, reversible seam. This stitch is common in industrial sewing machines for its reliability and neat finish.

Q: Why choose an industrial single-needle lock stitch machine with a needle guard?

A: Industrial single-needle models excel in high-speed, consistent stitching for thick materials. The needle guard prevents accidental needle breaks, ensuring operator safety and reduced downtime.

Q: Can a Happy Lock sewing machine handle delicate fabrics?

A: Yes, with adjustable tension and stitch length settings, it accommodates both delicate and heavy fabrics. The needle guard also minimizes fabric damage during stitching.

Q: How to maintain an industrial lock stitch sewing machine?

A: Regularly clean lint, oil moving parts, and inspect the needle guard. Proper maintenance ensures longevity and consistent stitch quality, especially in high-volume production.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025