hand leather sewing machine

The Art of Hand Leather Sewing Machines Crafting Timeless Goods

In an era dominated by automated production processes and digital craftsmanship, the timeless art of hand leather sewing has carved out a distinctive niche that values tradition, quality, and the unique touch of human artistry. Central to this craft is the hand leather sewing machine, a tool that bridges the gap between manual dexterity and machine efficiency. This article delves into the intricacies of hand leather sewing machines, their significance, and the craftsmanship involved in creating leather goods that stand the test of time.

The Historical Context

The history of leatherworking can be traced back thousands of years when early humans adapted animal hides for clothing and shelter. With the advancement of technology, the industrial revolution introduced machines that transformed leather production, but the hand sewing technique has remained relevant, especially for artisans who prioritize quality over quantity. Hand leather sewing machines emerged as essential tools for leatherworkers, combining traditional sewing techniques with mechanization to enhance the speed and efficiency of the craft.

The Mechanics of Hand Leather Sewing Machines

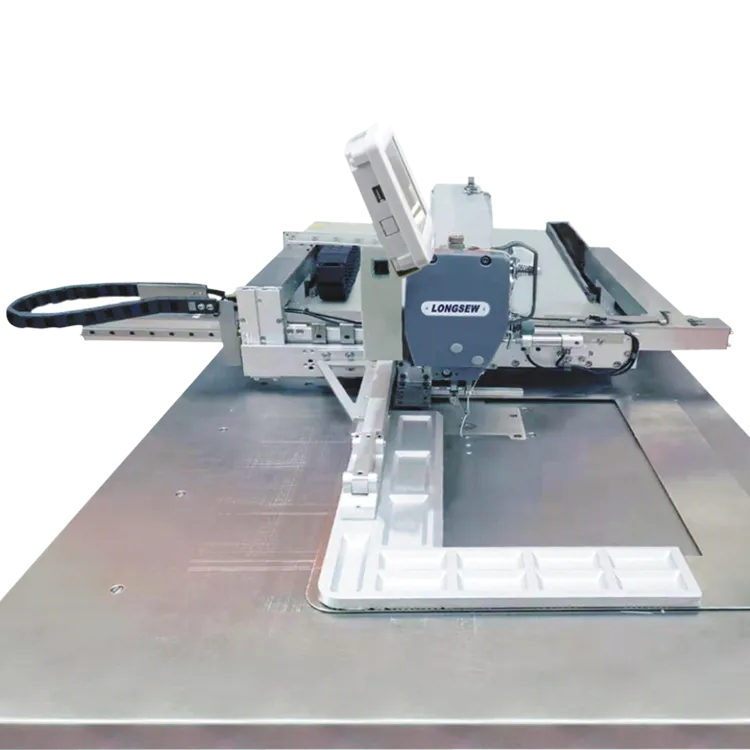

Hand leather sewing machines, often referred to as walking foot machines, are designed specifically for handling heavy materials like leather. Unlike standard sewing machines, these specialized machines feature a unique mechanism that allows the presser foot to walk along the leather, providing even feeding and preventing the material from slipping. This feature is crucial when working with thick leathers, ensuring that stitches are consistent and strong.

The machines typically use a combination of straight and zigzag stitching techniques, offering versatility for various leather goods, whether it be wallets, belts, bags, or even intricate designs for bespoke items. The hand leather sewing machine operates at a slower pace than industrial machines, allowing artisans to maintain control over their work and focus on precision and detail – qualities that are indispensable in leathercraft.

The Craftsmanship Involved

hand leather sewing machine

Crafting leather goods requires a high level of skill and a deep understanding of materials. Artisans often choose leather based on its grade, durability, and texture, opting for vegetable-tanned leather for its environmental benefits and rich patina over time. The process of creating leather goods involves meticulous planning, including pattern making, cutting, and edge finishing.

Once the pieces are cut, the artisan will prepare the leather by punching holes for stitching, a task that demands precision and attention to detail. The leather is then loaded onto the hand sewing machine, where the sewing begins. Each stitch is performed with care, often using waxed thread for added strength and longevity. This step is not just functional; it's also artistic, as the quality of the stitching can greatly influence the overall aesthetic of the piece.

The Benefits of Hand Leather Sewing Machines

One of the primary advantages of hand leather sewing machines is their ability to create robust and durable seams. Hand-sewn items are often superior in quality compared to mass-produced counterparts due to the meticulous nature of the craft. The strength of hand stitching can be attributed to the use of backstitches, which help withstand stress and prevent unraveling over time. This durability is particularly significant for leather products, which are intended to age beautifully and serve their purpose for years, if not decades.

Moreover, hand leather sewing imparts an element of customization. Artisans can create one-of-a-kind pieces tailored to individual customer preferences, further enhancing the value of the product. This personal touch resonates with consumers increasingly seeking authentic, handcrafted items over generic, mass-produced goods.

Conclusion The Revival of Handcrafted Excellence

In a world where fast fashion often dominates, the resurgence of interest in hand leather sewing machines and traditional craftsmanship represents a yearning for authenticity and quality. Artisans around the globe are embracing these machines to create products that not only fulfill a functional role but also tell a story – that of skill, tradition, and artistry.

As consumers become more conscious of their purchasing decisions, the demand for handcrafted leather goods continues to rise. This shift challenges the conventional notions of commerce and craftsmanship, allowing the artistry of leatherworking to flourish again. Ultimately, hand leather sewing machines are not merely tools; they are a testament to the enduring legacy of human creativity and the age-old practice of turning raw materials into cherished possessions. By embracing this art form, we celebrate the value of skilled craftsmanship in a modern world.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025