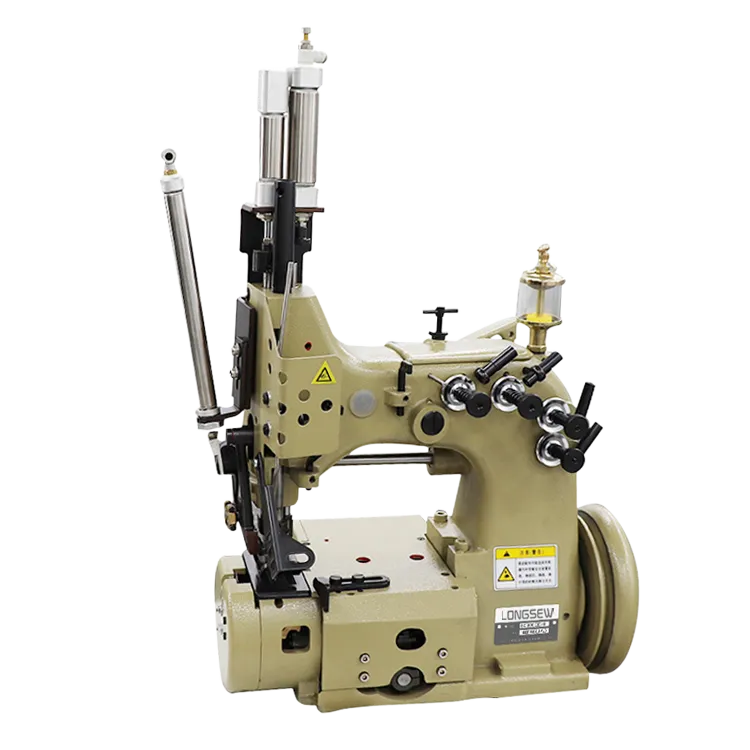

garments overlock machine

The Importance of Overlock Machines in Garment Manufacturing

In the fast-paced world of garment manufacturing, efficiency and precision are paramount. One of the essential tools in any garment factory is the overlock machine. Also known as a serger, this machine plays a crucial role in finishing the edges of fabric to prevent fraying and create a clean, professional look. With the rise of fashion trends and rapid production demands, understanding the significance of overlock machines in the garment industry is essential for both manufacturers and consumers.

What is an Overlock Machine?

An overlock machine is designed to sew over the edge of one or two pieces of fabric, resulting in a secure seam while simultaneously trimming the excess fabric. Unlike standard sewing machines, overlock machines typically have multiple threads that allow for more flexibility and stronger seams. They can sew, trim, and finish edges in one pass, significantly speeding up the production process. Different models may include features such as differential feed, which helps to manage various fabric types and prevent stretching or puckering.

Benefits of Using Overlock Machines

1. Efficiency In garment manufacturing, time is money. Overlock machines streamline the sewing process by allowing manufacturers to complete multiple tasks at once. This efficiency not only increases productivity but also reduces labor costs.

2. Professional Finish Overlocked seams are not only practical but also aesthetically pleasing. The clean finish provided by an overlock machine gives garments a polished and high-quality appearance, which is crucial in the competitive fashion market.

3. Versatility Overlock machines can handle various fabric types, from lightweight knits to heavy woven materials. This versatility makes them ideal for diverse garment production, accommodating the ever-changing fashion trends and consumer demands.

4. Durability The seams created by overlock machines are generally stronger than those made with standard sewing machines. The use of multiple threads and the encasing of raw edges help enhance the durability of seams, making garments more resistant to wear and tear.

5. Creative Possibilities With advanced overlock machines, manufacturers can experiment with different stitch patterns and decorative finishes. This feature allows for creativity in design, adding unique elements to garments that set them apart in the market.

garments overlock machine

Types of Overlock Machines

There are several types of overlock machines available, each designed for specific tasks and levels of production. The most common types include

- 2-thread Overlock Machine Ideal for lightweight fabrics and delicate seams, often used in garments like lingerie or lightweight blouses.

- 3-thread Overlock Machine Offers a robust stitch that is suitable for most fabrics and is widely used in various garment types.

- 4-thread Overlock Machine Known for its strength and versatility, this machine is perfect for heavier fabrics and provides the best finish for seams while offering additional durability.

- Cover Stitch Machine This specialized machine provides a professional double-needle cover stitch, commonly used on hems and necklines in knit garments.

The Future of Overlock Machines in Fashion

As the garment industry evolves, the integration of technology into overlock machines continues to advance. Modern machines are increasingly equipped with computerized controls and automated features that enhance precision and reduce human error. Additionally, with the growing trend towards sustainability, manufacturers are exploring innovative ways to minimize fabric waste during the overlocking process, further emphasizing the importance of this machinery.

In conclusion, overlock machines are indispensable in the garment manufacturing process. Their ability to provide efficient, durable, and professional finishes makes them a vital investment for any clothing manufacturer. As the industry continues to innovate, the role of overlock machines will undoubtedly expand, ensuring that they remain at the forefront of garment production. Whether it’s a casual T-shirt or a high-end dress, the impact of overlock machines is evident in the quality and longevity of the garments we wear.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025