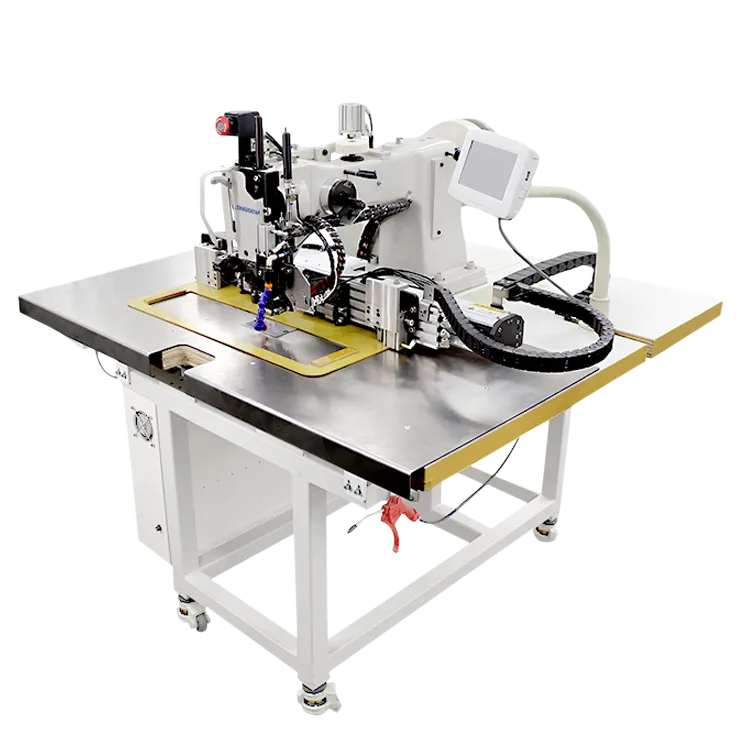

fibc spout sewing machine

The Importance of FIBC Spout Sewing Machines in Modern Packaging

In the realm of industrial packaging, FIBC (Flexible Intermediate Bulk Container) bags are gaining prominence due to their versatility and efficiency. These bags, designed to carry large quantities of bulk materials such as grains, chemicals, and construction materials, are an essential part of various industries. However, the effectiveness of FIBC bags largely depends on how well they are constructed, particularly the seams. This is where FIBC spout sewing machines come into play, revolutionizing the way these bags are manufactured.

The Importance of FIBC Spout Sewing Machines in Modern Packaging

One of the key advantages of FIBC spout sewing machines is their speed and efficiency. Modern machines are equipped with advanced technology that enables rapid sewing without compromising on quality. This increased speed translates into higher productivity for manufacturers, allowing them to meet the growing demand for FIBC bags in various sectors. Additionally, some machines come with automatic functions that reduce the need for manual intervention, further streamlining the manufacturing process.

fibc spout sewing machine

In addition to speed, durability is a primary concern in the production of FIBC bags. The materials used are often heavy-duty, requiring robust stitching to withstand the weight of the contents being transported. FIBC spout sewing machines are designed to handle these tough materials, utilizing strong threads and specialized sewing techniques to produce seams that can resist tearing and fraying. This durability ensures the bags can endure the rigors of transportation and storage without failure.

Furthermore, the versatility of FIBC spout sewing machines cannot be overlooked. Many machines are equipped with adjustable settings that allow manufacturers to create different types of spouts and handles, accommodating a wide range of bag designs. This versatility allows businesses to customize their FIBC products according to specific customer requirements or industry standards, providing a competitive edge in the market.

Moreover, the integration of technological advancements into FIBC spout sewing machines has led to enhanced precision and consistency in seam production. Features such as computer numerical control (CNC) and automatic thread trimming contribute to a higher quality output while minimizing waste. With consistent quality, manufacturers can build a strong reputation for reliability, which is essential in the highly competitive packaging industry.

In conclusion, FIBC spout sewing machines are an indispensable tool in the production of high-quality bulk bags. Their ability to combine speed, durability, and versatility makes them vital for manufacturers looking to meet the demands of various industries. As the global economy continues to evolve, the need for efficient and reliable packaging solutions will only increase, further solidifying the importance of these specialized machines in the production line. Investing in advanced FIBC spout sewing machines is not just a matter of efficiency but also a strategic move toward achieving long-term success in the packaging industry.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025