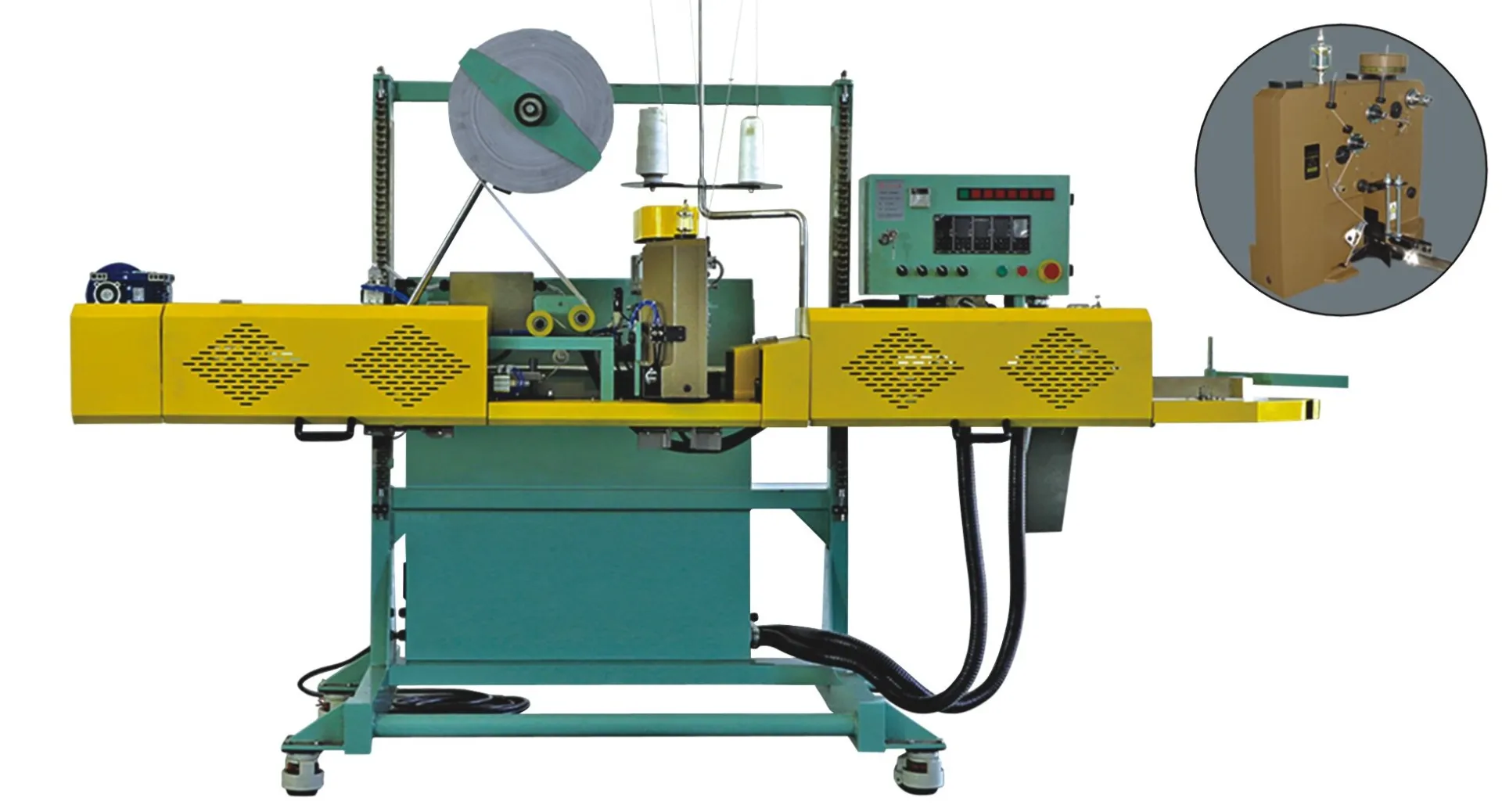

fibc spout sewing machine

The FIBC Spout Sewing Machine Revolutionizing Bulk Packaging Solutions

In the ever-evolving world of industrial packaging, the need for efficiency and precision has led to the development of specialized machinery designed to cater to specific requirements. One such innovation is the FIBC (Flexible Intermediate Bulk Container) spout sewing machine. This incredible piece of equipment has become a cornerstone in the production of FIBCs, which are widely used for storing and transporting bulk materials across various industries, including agriculture, chemical, and construction.

FIBCs are designed to handle large quantities of dry, flowable products, making them a preferred choice for many suppliers. These bags, often referred to as big bags, can hold from a few hundred to several thousand kilograms of material. The construction of these bags involves multiple components, and one of the most critical aspects is the spout, which allows for easy filling and discharging. The FIBC spout sewing machine focuses specifically on the spout assembly, ensuring durability and reliability in construction.

Enhanced Efficiency and Precision

One of the primary advantages of the FIBC spout sewing machine is the efficiency it brings to the manufacturing process. Traditional sewing methods, which can be labor-intensive and time-consuming, are replaced with automated systems that speed up production significantly. These machines are designed to work with various materials, including polypropylene, a material commonly used in FIBC production due to its robustness and lightweight properties.

Moreover, the precision of the stitching is crucial. Inadequate seam integrity can lead to leaks and product losses, which can be financially detrimental to businesses. The FIBC spout sewing machine ensures that every stitch is consistent and meets stringent quality standards. High-speed sewing mechanisms reduce the rate of human error while increasing output, making this equipment indispensable in any commercial FIBC manufacturing setting.

Versatility and Customization

Modern FIBC spout sewing machines are not one-size-fits-all. They come equipped with versatile features, allowing manufacturers to customize bag sizes and spout designs according to the demands of their clientele. With the capability to adjust for different thread types and stitch patterns, these machines can accommodate a variety of products, from agricultural grains to heavy chemicals. As industries evolve, flexibility in design is crucial, making these sewing machines an essential investment for forward-thinking companies.

fibc spout sewing machine

Sustainable Production

In today's world, where sustainability has taken center stage, the FIBC spout sewing machine also aligns with eco-friendly practices. The machinery is designed to minimize waste during the production process, utilizing materials more efficiently and thereby reducing the overall environmental impact. With a focus on using recyclable materials, manufacturers can produce bags that not only serve their functional purpose but also contribute to a greener planet.

The Future of FIBC Manufacturing

As technology advances, the future of FIBC spout sewing machines seems promising. Innovations such as smart technology integration, which enables real-time monitoring and automated adjustments, are on the horizon. This will further enhance the capabilities of these machines, allowing for predictive maintenance and operational efficiency.

Additionally, as more industries shift towards more sustainable packaging solutions, the demand for high-quality, efficient FIBC production will continue to grow. The FIBC spout sewing machine will undoubtedly adapt to meet these changing needs while helping businesses remain competitive in an increasingly global marketplace.

Conclusion

In conclusion, the FIBC spout sewing machine is a groundbreaking innovation in the field of bulk packaging. Its ability to enhance efficiency, provide precision, offer customization, and support sustainable practices makes it a vital component in the manufacturing processes of various industries. As we move forward, the role of such specialized machinery will only become more pronounced, helping businesses adapt to the challenges of modern packaging demands. Investing in an FIBC spout sewing machine is not just an operational choice; it's a strategic decision that can lead to significant advancements in productivity, sustainability, and profitability. In this ever-changing landscape, companies that leverage advanced sewing technology will undoubtedly find themselves at the forefront of the industry.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025