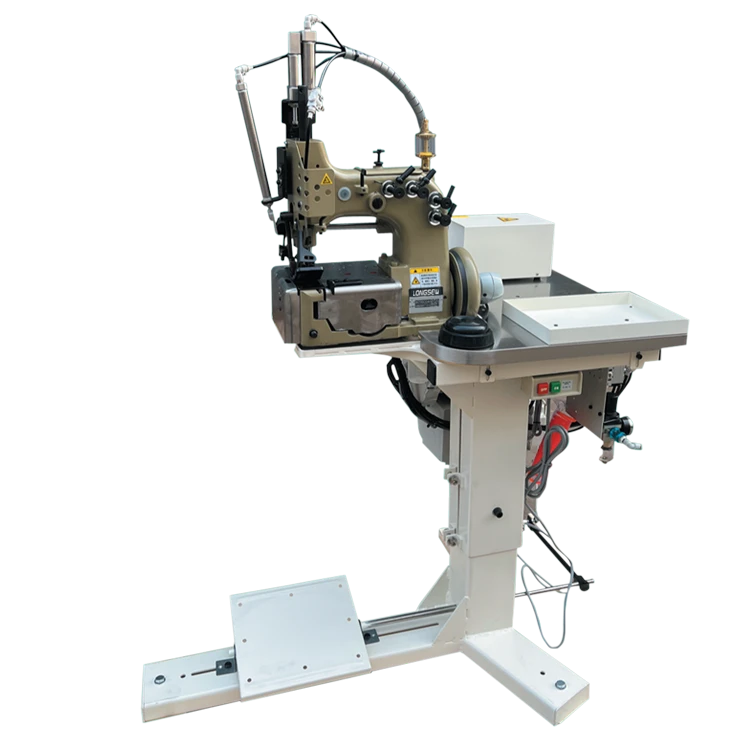

fibc sewing machine

The Essential Role of FIBC Sewing Machines in the Packaging Industry

In the modern packaging industry, the demand for efficient and durable solutions has led to the rise of bulk packaging, most notably through the use of Flexible Intermediate Bulk Containers (FIBCs). These large bags are commonly used for transporting dry, flowable products such as grains, chemicals, and construction materials. To ensure the quality and durability of FIBCs, the sewing machine used in their production plays a crucial role. This article explores the significance of FIBC sewing machines, their features, and their impact on manufacturing quality.

Understanding FIBCs

Flexible Intermediate Bulk Containers (FIBCs) are large, flexible bags that can hold between 500 to 2,000 kilograms of material. They are made from woven polypropylene, a lightweight yet strong material that is resistant to various chemicals and environmental conditions. FIBCs offer a sustainable alternative to traditional packaging methods due to their reusability and recyclability, making them popular across diverse industries like agriculture, construction, and chemical manufacturing.

The Importance of Sewing in FIBC Production

The construction of FIBCs involves various processes, and sewing is a pivotal aspect. Proper stitching ensures that the bags can withstand the weight of the contents and potential environmental stressors during transportation. High-quality sewing is essential for preventing leaks, ensuring that the bag holds its contents securely while minimizing waste.

FIBC sewing machines are specifically designed to handle the robust materials used in bag production. These machines must deliver consistent and reliable stitching, which requires precision engineering and high productivity. Factors such as thread type, seam strength, and stitching pattern must be carefully considered to meet industry standards and customer expectations.

Features of FIBC Sewing Machines

FIBC sewing machines are equipped with several specialized features to enhance their functionality

1. Heavy-Duty Construction These machines are built to handle the thick, woven polypropylene material used in FIBCs. They often come with reinforced frames to withstand heavy workloads.

fibc sewing machine

2. Multi-Needle Capability Many FIBC sewing machines use multiple needles and threads to create strong, secure seams. This feature is essential for reinforcing the bag's structure and preventing any potential ruptures.

3. Versatility Some FIBC sewing machines can be used for various stitching techniques, including straight stitches, zig-zag stitches, and even decorative stitching. This versatility allows manufacturers to produce bags tailored to specific customer needs.

4. Automatic Functions Advanced models of FIBC sewing machines come with automatic thread trimming, adjustable stitch length, and speed control options, enhancing efficiency and reducing labor costs.

5. Durability and Maintenance These sewing machines are designed for longevity, with easy-to-replace parts and minimal maintenance requirements. This ensures that production line downtimes are reduced, promoting continuous operation.

Impact on Manufacturing Quality

The choice of sewing machine significantly impacts the overall quality of the FIBCs produced. High-quality sewing machines produce bags that are not only durable but also meet regulatory standards for safety and reliability. Manufacturers who invest in top-tier FIBC sewing machines are better positioned in the competitive market, as they can provide products that withstand the test of time while minimizing product failure.

Moreover, the efficiency of these machines contributes to higher output rates, allowing companies to meet increasing demands without sacrificing quality. As industries evolve, the need for innovative and sustainable packaging solutions continues to rise; FIBC sewing machines will play a vital role in meeting these demands.

Conclusion

In conclusion, FIBC sewing machines are a fundamental component of the packaging industry, especially in the production of bulk bags. Their specialized features, durable construction, and role in ensuring high-quality output highlight their importance in manufacturing processes. As businesses increasingly lean towards sustainable practices, the demand for FIBCs – and by extension, the machines that produce them – is likely to grow. Investing in cutting-edge FIBC sewing technology will not only improve production efficiency but also enhance the overall quality of packaged goods, ensuring that manufacturers remain competitive in a rapidly evolving marketplace.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025