Innovative Solutions for Fibc Sewing Machine Technology in Modern Manufacturing

The Importance of FIBC Sewing Machines in the Packaging Industry

In the world of packaging, efficient and reliable machinery is essential for maintaining production standards and ensuring the quality of the final product. One of the most vital machines in this sector is the FIBC sewing machine, specifically designed for manufacturing Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags. FIBCs are widely used for transporting and storing bulk materials ranging from granules to powders, making them indispensable in various industries, including agriculture, chemicals, and construction.

Understanding FIBCs

Flexible Intermediate Bulk Containers are large, flexible containers that can hold significant volumes of materials. Made from woven polypropylene fabric, FIBCs can carry loads typically ranging from 500 kg to 2000 kg, making them an ideal solution for large-scale logistics and storage. The durability and strength of the material allow FIBCs to withstand harsh environmental conditions, ensuring the safety of the contents during transit.

The Role of Sewing Machines

A staple in the production of FIBCs, sewing machines specifically designed for this purpose are integral to ensuring that these bulk bags are both strong and reliable. Unlike conventional sewing machines, FIBC sewing machines come equipped with features tailored to handle thick, heavy-duty fabrics and multiple layers of material. The robust construction of these machines enables them to stitch through the layers without compromising on quality, which is crucial for maintaining the integrity of the bags.

Features of FIBC Sewing Machines

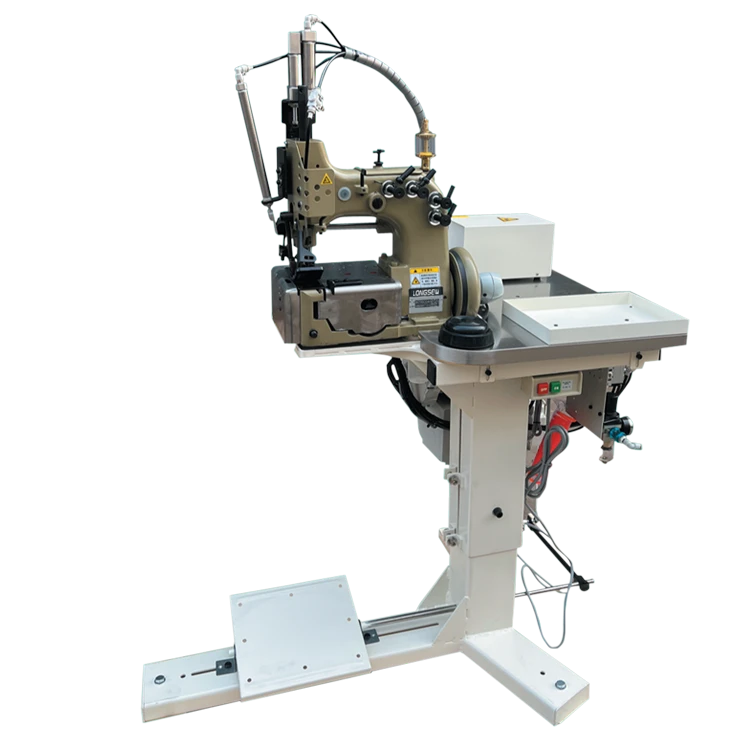

fibc sewing machine

Modern FIBC sewing machines boast several special features that enhance their functionality. These include

1. High Speed and Efficiency FIBC sewing machines are designed to operate at high speeds, significantly increasing production efficiency. This is particularly crucial in a fast-paced manufacturing environment where timely delivery is essential.

2. Heavy-Duty Needles and Threads The machines typically use heavy-duty needles and threads to ensure strong seams. This helps to prevent breakage and leakage, crucial factors in maintaining the performance of the bags.

3. Adjustable Stitch Length These machines often have adjustable stitch lengths to accommodate different fabric types and thicknesses, allowing for versatility in production.

4. User-Friendly Controls Many FIBC sewing machines come with advanced control panels that simplify operation and reduce the learning curve for new operators.

Conclusion

In summary, FIBC sewing machines are a fundamental component of the bulk bag manufacturing process. Their specialized capabilities ensure the production of high-quality, durable FIBCs that meet the demands of various industries. As the packaging industry continues to evolve, the importance of these machines will only grow, highlighting the need for continual innovation and investment in technology. Ultimately, reliable FIBC sewing machines not only enhance productivity but also contribute to the overall safety and efficiency of bulk material transportation and storage. With the rise in demand for sustainable packaging solutions, the role of FIBC sewing machines will be vital in shaping the future of the packaging industry.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025