Jan . 09, 2025 13:58

Back to list

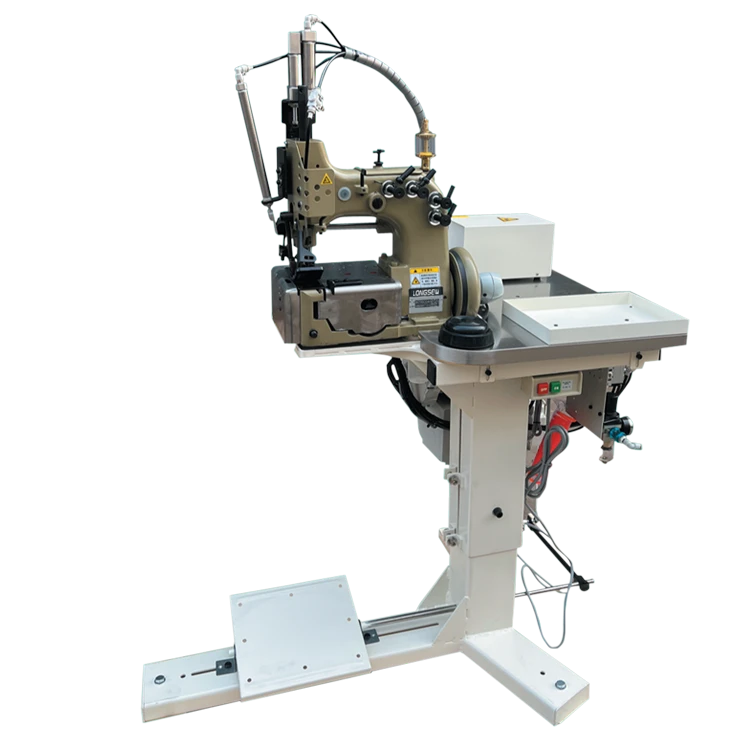

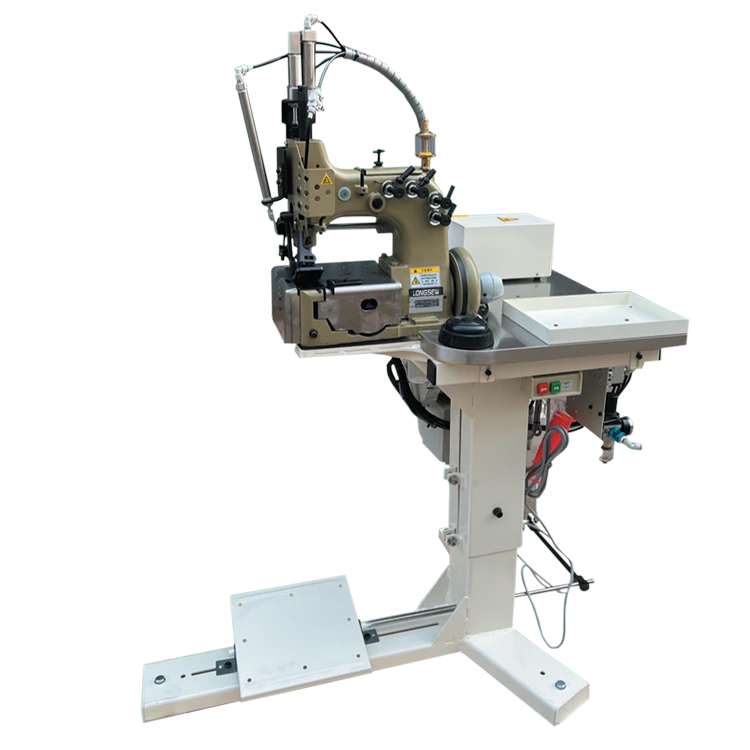

fibc sewing machine

When considering the optimization and efficiency of FIBC sewing machines in industrial applications, understanding the versatility and technological advancements is crucial. In recent years, the FIBC sewing machine has emerged as an indispensable tool, delivering unparalleled utility in producing Flexible Intermediate Bulk Containers (FIBCs), which are essential for transporting bulk goods across the globe.

Expertise in operating FIBC sewing machines comes with understanding the operational intricacies. Skilled technicians dedicated to this equipment are often tasked with routine maintenance, minimizing downtime and enhancing productivity. They ensure that all components, such as needles and loopers, are functioning optimally, reducing the risk of mechanical failures that could impact business operations. From a trustworthiness perspective, businesses invest in machines from reputable manufacturers who adhere to quality standards and certifications. These assurances are crucial, particularly in industries dealing with chemicals or food products, where safety and hygiene are non-negotiable. Reliable machines equipped with safety features and emergency stop functions reflect the manufacturer’s commitment to the users' safety and product integrity. Furthermore, the economic implications of employing state-of-the-art FIBC sewing machines cannot be overstated. By maintaining high-output capabilities and precision, companies can significantly cut costs associated with errors and reworks. Moreover, the introduction of eco-friendly threads and materials in the sewing process aligns with global sustainability standards, thus echoing a company's responsibility towards environmental conservation. In conclusion, FIBC sewing machines represent a blend of mechanical excellence and innovative technology. Their role in modern industries extends beyond mere production tools to becoming pillars of efficiency, reliability, and environmental responsibility. For businesses seeking to enhance their production processes, the strategic incorporation of these machines can forge paths to new opportunities, ensuring they remain competitive and trusted in their respective markets.

Expertise in operating FIBC sewing machines comes with understanding the operational intricacies. Skilled technicians dedicated to this equipment are often tasked with routine maintenance, minimizing downtime and enhancing productivity. They ensure that all components, such as needles and loopers, are functioning optimally, reducing the risk of mechanical failures that could impact business operations. From a trustworthiness perspective, businesses invest in machines from reputable manufacturers who adhere to quality standards and certifications. These assurances are crucial, particularly in industries dealing with chemicals or food products, where safety and hygiene are non-negotiable. Reliable machines equipped with safety features and emergency stop functions reflect the manufacturer’s commitment to the users' safety and product integrity. Furthermore, the economic implications of employing state-of-the-art FIBC sewing machines cannot be overstated. By maintaining high-output capabilities and precision, companies can significantly cut costs associated with errors and reworks. Moreover, the introduction of eco-friendly threads and materials in the sewing process aligns with global sustainability standards, thus echoing a company's responsibility towards environmental conservation. In conclusion, FIBC sewing machines represent a blend of mechanical excellence and innovative technology. Their role in modern industries extends beyond mere production tools to becoming pillars of efficiency, reliability, and environmental responsibility. For businesses seeking to enhance their production processes, the strategic incorporation of these machines can forge paths to new opportunities, ensuring they remain competitive and trusted in their respective markets.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025