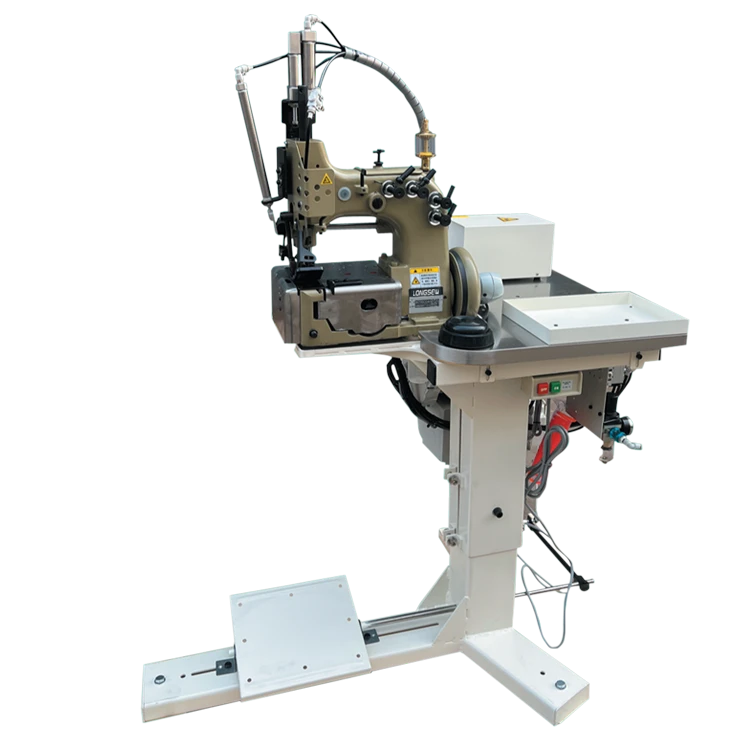

fibc sewing machine

The Importance of FIBC (Flexible Intermediate Bulk Container) Sewing Machines in Industrial Applications

In the world of industrial packaging, Flexible Intermediate Bulk Containers (FIBCs) are a vital component for transporting granular and powdery substances. Known for their durability, large capacity, and economic efficiency, FIBCs have transformed the way industries, particularly those dealing with bulk materials, operate. A crucial element in the production of these containers is the sewing machine specifically designed for FIBC manufacturing. This article explores the significance of FIBC sewing machines and highlights their essential features, benefits, and applications.

What Are FIBC Sewing Machines?

FIBC sewing machines are specialized industrial sewing machines designed to stitch the various components of flexible bulk containers. These machines are tailored to handle the heavy-duty fabric that comprises FIBCs, which is often made from woven polypropylene or polyethylene. Given the heavy demands of FIBC production, these sewing machines are engineered to provide high-speed stitching, precision, and durability, ensuring that the end product meets stringent quality and safety standards.

Key Features of FIBC Sewing Machines

1. Heavy-Duty Construction FIBC sewing machines are built robustly to withstand the demanding nature of manufacturing. They can handle thicker threads and heavy fabrics without compromising on performance.

2. High Sewing Speed These machines are designed for high-speed operation, allowing manufacturers to produce FIBCs in large quantities quickly. This efficiency is crucial in meeting tight production schedules.

3. Versatility Modern FIBC sewing machines can accommodate various sewing techniques, including double stitching and overlocking, ensuring the seams are strong and secure.

4. Automatic Features Many contemporary machines come with automatic functions like thread cutting and fabric feeding, which reduce manual labor and increase overall production efficiency.

Benefits of Using FIBC Sewing Machines

fibc sewing machine

1. Increased Productivity With high-speed operations and automated features, FIBC sewing machines drastically increase production rates, allowing manufacturers to meet larger orders promptly.

2. Cost Efficiency Although the initial investment might be significant, the long-term savings in labor costs, time, and material waste make these machines cost-effective.

3. Enhanced Quality Control The precision offered by these sewing machines ensures that each container is manufactured to meet quality standards, which is crucial when transporting sensitive or hazardous materials.

4. Adaptability to Different Products FIBC sewing machines can be adjusted to produce various types of bags, accommodating the diverse needs of different industries, from agriculture to construction.

5. Reduction in Production Time The efficiency of these machines leads to shorter turnaround times, enabling companies to respond quickly to market demands.

Applications of FIBC Sewing Machines

FIBC sewing machines find utility in various sectors

- Agriculture Used to pack fertilizers, seeds, and grains, ensuring safe transport and storage. - Food Industry Ideal for moving bulk food products such as sugar, flour, and dried fruits while adhering to safety standards. - Construction Essential for transporting building materials like sand and gravel, where durability is key. - Chemical Industry Perfect for packaging granulated or powdered chemicals, ensuring containment and safety.

Conclusion

FIBC sewing machines play a pivotal role in the manufacturing of bulk containers that are instrumental in various industrial sectors. Their heavy-duty design, high-speed capabilities, and versatility make them indispensable in a world that demands efficiency and reliability in packaging solutions. As industries continue to evolve and grow, the importance of advanced sewing technologies for FIBCs will only increase, driving innovation and sustainability in the manufacturing process. Embracing these machines not only enhances productivity but also contributes to a more efficient supply chain, making them an essential investment for any serious manufacturer in today's competitive market.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025