Automated Sewing Solutions for FIBC Bags Using Advanced Computer Technology

The Future of Textile Manufacturing The Rise of FIBC Computerized Auto Sew Technology

In the fast-paced world of textile manufacturing, innovation is the key to staying competitive. One of the most exciting advancements in this realm is the introduction of Computerized Auto Sew technology specifically designed for the production of Flexible Intermediate Bulk Containers (FIBCs). These large, flexible bags are used for the storage and transportation of bulk materials and have become essential in various industries, from agriculture to chemicals. The integration of advanced sewing technologies is revolutionizing the way FIBCs are manufactured, enhancing efficiency, precision, and sustainability.

Understanding FIBC and Its Importance

FIBCs, often known as big bags or bulk bags, are designed to hold large quantities of dry goods, powders, and granules. Their versatility makes them a preferred choice for many industries, including food, pharmaceuticals, construction, and mining. The demand for FIBCs has been growing steadily, driven by the global increase in trade and the need for efficient packaging solutions.

However, traditional manufacturing methods for these bags can be labor-intensive, often leading to inconsistencies in quality and an increased rate of defects. This is where Computerized Auto Sew technology comes into play, offering a solution that not only improves the production process but also elevates the overall quality of the end product.

The Advantages of Computerized Auto Sew Technology

1. Increased Efficiency One of the primary advantages of computerized auto sewing machines is their ability to operate at high speeds without compromising on quality. These machines can stitch, cut, and handle multiple tasks simultaneously, significantly reducing the time required to manufacture each bag. This efficiency allows manufacturers to meet larger orders and respond quickly to market demands.

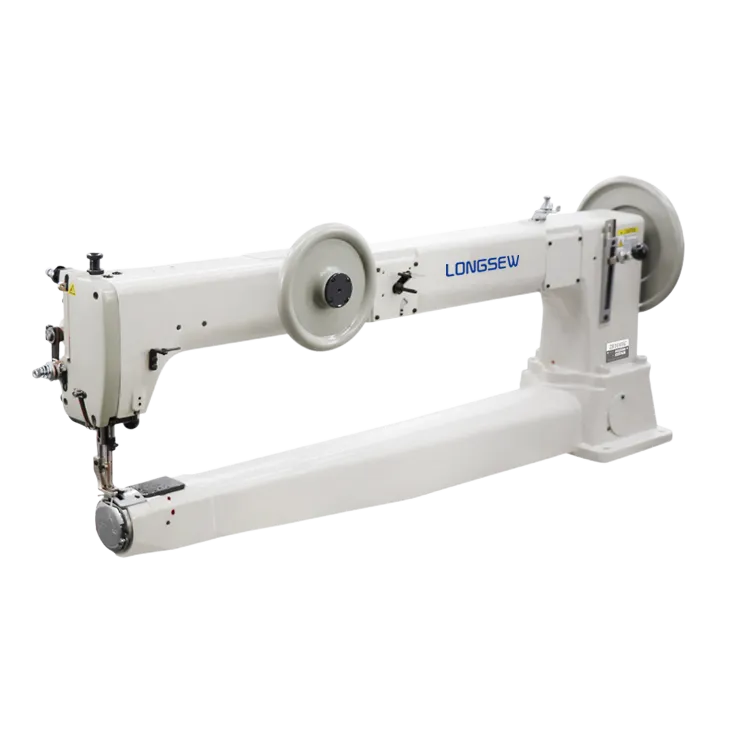

fibc computerized auto sew

2. Enhanced Precision The precision of computerized systems is unmatched. Each stitch is executed with exacting accuracy, ensuring that seams are strong and reliable. This is particularly crucial for FIBCs, as they must endure handling, transportation, and storage without failure. The consistency offered by auto sewing technology also minimizes the risk of defects, leading to higher quality standards.

3. Customization Capabilities With advancements in software integration, manufacturers can easily customize their FIBCs based on specific client needs. Whether it is altering dimensions, choosing different materials, or modifying the stitching pattern, auto sewing machines can adapt to a wide range of requirements, allowing for a more personalized product.

4. Labor Cost Reduction Although the initial investment in computerized sewing technology can be significant, the long-term savings are substantial. Fewer human operators are required, which reduces labor costs and the likelihood of human error. Additionally, this technology can relieve workers from monotonous tasks, allowing them to focus on more complex aspects of production.

5. Sustainability In today’s environmentally conscious market, manufacturers are striving to implement sustainable practices. Computerized auto sew technology enhances material utilization, reducing waste during the cutting and sewing processes. Moreover, strong and consistent seams lead to fewer bags being scrapped, further contributing to a sustainable production model.

Conclusion

As the textile manufacturing industry continues to evolve, the adoption of Computerized Auto Sew technology for the production of Flexible Intermediate Bulk Containers represents a significant leap forward. This transformation not only streamlines production processes but also enhances product quality, customization capabilities, and sustainability. As more manufacturers embrace these advanced technologies, we can expect to see a shift in how textiles are produced, ultimately leading to a more efficient and eco-friendly industry.

The future looks bright for FIBC manufacturing, and computerized auto sewing machines will undoubtedly play a pivotal role in shaping that future. By combining technological innovation with traditional manufacturing practices, companies can position themselves at the forefront of the industry, ready to meet the challenges of an increasingly competitive global market.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025