fibc bag producing line

The FIBC Bag Producing Line Revolutionizing Bulk Packaging

FIBC bags, or Flexible Intermediate Bulk Containers, have become an integral part of the modern packaging landscape, especially for industries that require the storage and transportation of bulk materials. The production of these versatile bags involves a carefully designed FIBC bag producing line that ensures efficiency, quality, and adaptability to various user needs.

Understanding FIBC Bags

FIBC bags are large flexible bags made from woven polypropylene fabric, designed to carry a wide range of dry, flowable products. Their capacity typically ranges from 500 kg to 3000 kg, making them ideal for industries such as agriculture, chemicals, food, and construction. Their lightweight yet robust structure makes them a preferred choice over traditional bulk bags, not only due to their strength but also for their cost-effectiveness and environmental considerations.

The Importance of a High-Quality Producing Line

The quality of FIBC bags largely hinges on the machinery and processes used in the producing line. A state-of-the-art FIBC bag producing line employs advanced technology to ensure that each bag meets stringent quality standards. The efficiency of the production line not only speeds up manufacturing but also ensures that automated systems minimize the risk of human error, leading to a more consistent product.

Key Components of the FIBC Bag Producing Line

1. Fabric Preparation The process begins with the preparation of the polypropylene fabric. High-quality raw materials are selected and treated to enhance durability and strength. The fabric is woven into a flat layout before moving on to the cutting station.

fibc bag producing line

2. Cutting and Shaping Once the fabric has been prepared, it is cut into the required size for the bags. Advanced cutting machines ensure precision, allowing for various bag shapes and sizes tailored to customer specifications.

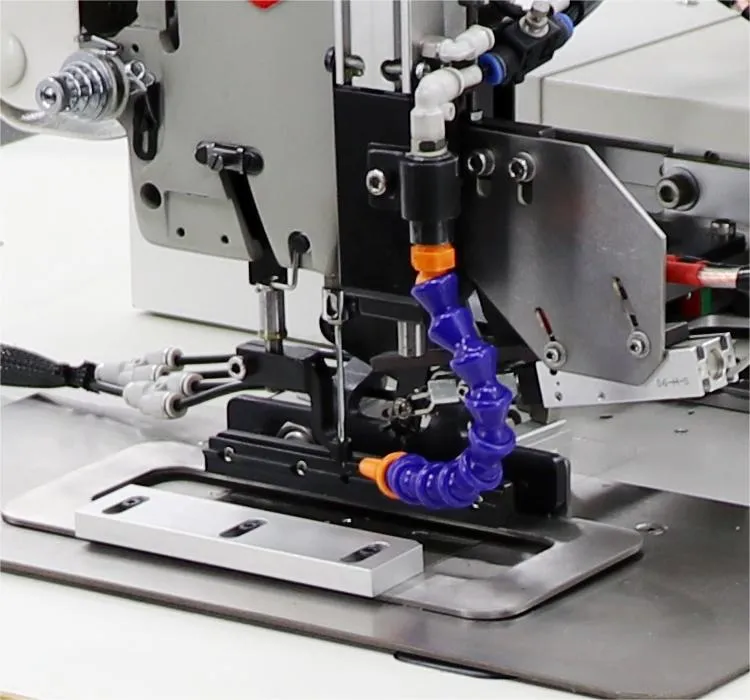

3. Sewing and Assembly After cutting, the fabric pieces are sewn together using industrial sewing machines. This step is critical as it determines the bag's load-bearing capacity. Some FIBC designs incorporate additional reinforcements, such as corner loops or straps, which are also sewn during this stage.

4. Quality Control A robust quality control system is essential in any producing line. Throughout the manufacturing process, bags are tested for strength, flexibility, and dimensional accuracy. This step ensures that only bags meeting the strict quality standards make it to the market.

5. Printing and Customization Many clients require specific branding or labeling on their FIBC bags. The printing station allows for customization, where logos, product information, and handling instructions can be printed directly onto the bags using advanced printing technology.

6. Packaging and Shipping Once the bags have passed all quality checks, they are folded, stacked, and packaged for shipment. Efficient packing techniques ensure that bags are delivered without damage and remain in pristine condition until they reach the end user.

Conclusion

The FIBC bag producing line plays a pivotal role in enhancing the efficiency and quality of bulk packaging solutions. As businesses continue to seek sustainable and efficient methods of transporting materials, the importance of high-quality FIBC bags becomes increasingly apparent. With advancements in manufacturing technology, companies can produce customizable and durable bags that cater to the diverse needs of various industries.

In conclusion, as we look toward the future, we can anticipate further innovations in the FIBC bag producing line that will not only continue to streamline the production process but also enhance the overall utility and sustainability of flexible bulk packaging. This evolution is critical in a world where logistics, efficiency, and environmental responsibility are more important than ever.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025