Jan . 13, 2025 17:13

Back to list

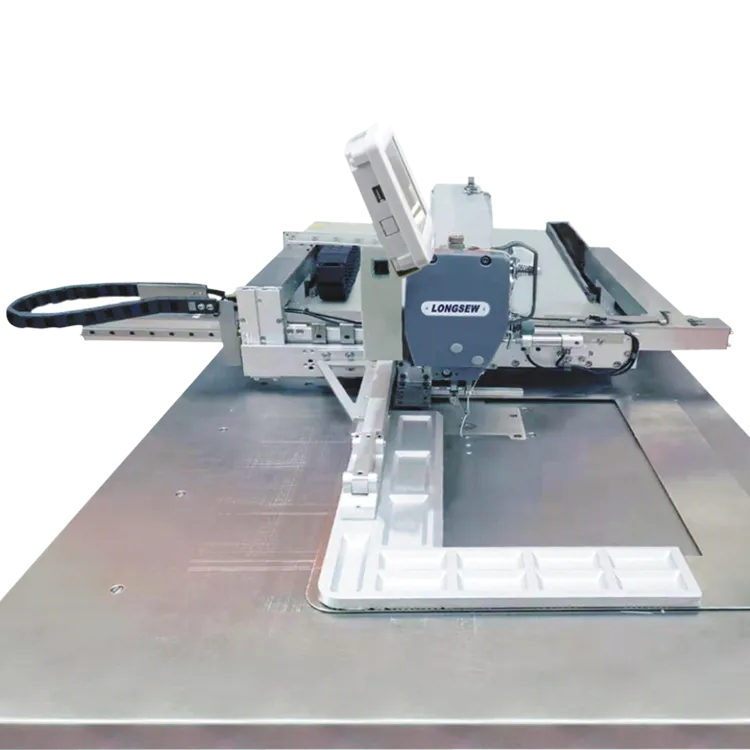

FIBC Bag / Jumbo Bag / Bulk Bag Single Needle Lock Stitch Top & Bottom Feeding Sewing Machine GSC367 /GSC367TD /GSC367TDZ/ GSC367-L

Double needle chain stitch sewing machines are revolutionizing the textile manufacturing industry, offering enhanced durability and superior finish for a variety of apparel and home textiles. In-depth exploration of these machines reveals their unparalleled advantage over traditional sewing techniques, making them an indispensable asset in modern sewing operations.

From an authoritative standpoint, industry reports and studies consistently highlight the advantages of double needle chain stitch sewing machines. The durability of chain stitches is well-documented, offering a solution to common issues such as seam puckering and stitch breakage. Apparel manufacturers who have integrated these machines into their production lines report fewer returns and complaints related to garment failure, thereby improving customer satisfaction and trust in their brand. Trustworthiness is a cornerstone of the relationship between manufacturers and consumers. Double needle chain stitch sewing machines contribute to this by ensuring that the garments produced are of enduring quality. The reliability of the stitching ensures that consumers can trust the longevity of the apparel they purchase, fostering brand loyalty and promoting positive word-of-mouth. Overall, investing in a double needle chain stitch sewing machine is a strategic decision for textile manufacturers aiming to improve their product offerings. These machines not only enhance the aesthetic appeal and functionality of garments but also elevate the manufacturing process to a level that aligns with the highest standards of quality and efficiency in the industry. The adoption of such advanced sewing technology underscores a commitment to excellence, reinforcing the manufacturer's position as an industry leader. In a market where precision, durability, and quality are paramount, double needle chain stitch sewing machines stand as a testament to the possibilities of modern sewing technology. Their impact on both production efficiency and product quality underscores the transformative role they play in the ever-evolving textile industry. As manufacturers continue to embrace these advancements, consumers can look forward to even greater innovations in the products they trust and cherish.

From an authoritative standpoint, industry reports and studies consistently highlight the advantages of double needle chain stitch sewing machines. The durability of chain stitches is well-documented, offering a solution to common issues such as seam puckering and stitch breakage. Apparel manufacturers who have integrated these machines into their production lines report fewer returns and complaints related to garment failure, thereby improving customer satisfaction and trust in their brand. Trustworthiness is a cornerstone of the relationship between manufacturers and consumers. Double needle chain stitch sewing machines contribute to this by ensuring that the garments produced are of enduring quality. The reliability of the stitching ensures that consumers can trust the longevity of the apparel they purchase, fostering brand loyalty and promoting positive word-of-mouth. Overall, investing in a double needle chain stitch sewing machine is a strategic decision for textile manufacturers aiming to improve their product offerings. These machines not only enhance the aesthetic appeal and functionality of garments but also elevate the manufacturing process to a level that aligns with the highest standards of quality and efficiency in the industry. The adoption of such advanced sewing technology underscores a commitment to excellence, reinforcing the manufacturer's position as an industry leader. In a market where precision, durability, and quality are paramount, double needle chain stitch sewing machines stand as a testament to the possibilities of modern sewing technology. Their impact on both production efficiency and product quality underscores the transformative role they play in the ever-evolving textile industry. As manufacturers continue to embrace these advancements, consumers can look forward to even greater innovations in the products they trust and cherish.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025