Computerized Sewing Machine for FIBC Bag Production Efficiency and Precision

The Evolution of FIBC Bag Production Embracing Computerized Sewing Machines

In today’s rapidly evolving manufacturing landscape, the production of bulk bags, commonly known as Flexible Intermediate Bulk Containers (FIBCs), has become an essential aspect of various industries including agriculture, construction, and chemicals. The ongoing advancements in technology have transformed the production process, making it more efficient and cost-effective. One noteworthy innovation is the implementation of computerized sewing machines in FIBC bag manufacturing. This article explores the impact of computerized sewing technology on the production of FIBC bags, focusing on efficiency, quality, and sustainability.

Understanding FIBC Bags

FIBC bags are versatile containers designed to hold and transport bulk materials. Constructed from durable woven polypropylene fabric, these bags have the capacity to carry weights ranging from 500 to 2000 kg. The significance of FIBC bags lies in their ability to facilitate the bulk transportation of diverse products such as grains, chemicals, and minerals. However, the quality of these bags largely depends on the precision and durability of their seams, which protect the contents from spillage and contamination.

Traditional vs. Computerized Sewing Machines

Historically, sewing FIBC bags involved manual processes or semi-automatic machines utilizing less sophisticated technology. While these methods were effective, they often resulted in inconsistencies in seam quality, increased production time, and heightened labor costs. The introduction of computerized sewing machines marks a revolutionary change in the industry. These advanced machines feature programmable sewing patterns, automated adjustments, and precise tension control, greatly enhancing the production quality of FIBC bags.

Computerized sewing machines can be programmed to execute complex stitching patterns, allowing manufacturers to produce various bag sizes and designs with minimal manual intervention. This technology not only streamlines the production process but also significantly reduces the likelihood of human error, resulting in more consistent and reliable sewing quality.

Benefits of Computerized Sewing Machines in FIBC Production

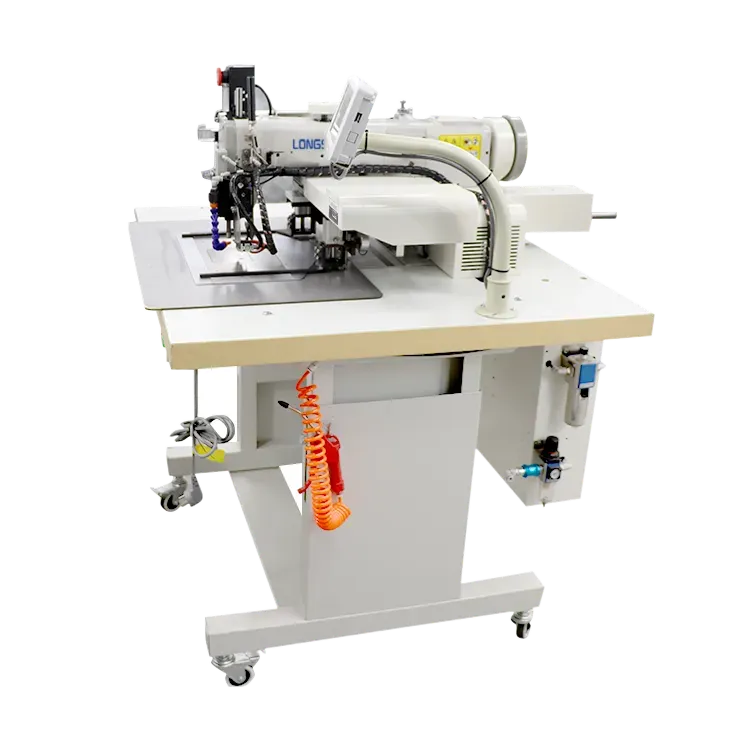

fibc bag computerized sewing machine

1. Enhanced Efficiency One of the primary advantages of computerized sewing machines is their ability to significantly speed up the production process. Automated functionalities allow for faster stitching, minimizing downtime and increasing overall productivity. This efficiency is crucial in meeting the rising demand for FIBC bags across various sectors.

2. Improved Quality Control Computerized sewing technology enables manufacturers to maintain stringent quality control standards. By utilizing advanced sensors and monitoring systems, these machines can detect inconsistencies in stitching and automatically adjust parameters to ensure that every bag meets the required specifications. This leads to fewer defects and higher overall product quality.

3. Versatility in Production The adaptability of computerized sewing machines allows manufacturers to create a wide range of bag styles tailored to specific industry needs. Whether it’s an open-top bag, a vented bag, or a bag with various types of closures, these machines can be programmed to handle different designs without the need for extensive retooling.

4. Cost Reduction Although the initial investment in computerized sewing machines may be significant, the long-term savings are substantial. By increasing production efficiency and reducing labor costs, manufacturers can achieve a quicker return on investment. Moreover, the reduction in waste and defects translates into lower material costs and improved profit margins.

5. Sustainability In line with global efforts towards sustainability, computerized sewing machines can contribute to greener manufacturing processes. By minimizing fabric waste through precise cutting and sewing, these machines help reduce the environmental impact associated with FIBC production. Additionally, manufacturers can optimize energy consumption by employing machines that operate with improved efficiency.

Conclusion

The integration of computerized sewing machines into FIBC bag production has undeniable implications for the industry. By improving efficiency, enhancing quality control, and promoting sustainable practices, this technology is reshaping the way manufacturers operate. As businesses continue to adapt to the demands of a dynamic market, the reliance on computerized solutions is set to increase. Ultimately, the future of FIBC bag manufacturing lies in the synergy between advanced technology and traditional craftsmanship, paving the way for innovation and growth in the industry.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025