High Efficiency Sewing Machine for FIBC Bag Baffles with Advanced Features

The Evolution and Importance of FIBC Bag Baffle Sewing Machines

Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags, have become indispensable tools in various industries, including agriculture, food, chemicals, and construction. Given their widespread use, the demand for efficient, reliable, and precise sewing machines specifically designed for constructing these bags has surged. One of the most significant advancements in this realm is the development of the FIBC bag baffle sewing machine.

Understanding FIBC Bags and Baffles

FIBC bags are designed to hold large quantities of materials and are commonly made from woven polypropylene. They feature a unique construction that allows for easy filling, storage, and transportation of bulk products. A crucial element of many FIBC bags is the baffle, a reinforcing structure sewn into the bag that helps maintain its shape, prevents bulging, and maximizes storage efficiency. The baffle allows the bag to have a square or rectangular shape, making it easier to stack and load compared to traditional round bags.

The Role of Baffle Sewing Machines

The baffle sewing process is critical because it directly impacts the strength, durability, and functionality of the FIBC bags. Baffle sewing machines are specialized devices that ensure precision in stitching the baffles and the main body of the bag. These machines are engineered to handle heavy-duty materials and perform reliably over long production runs.

1. Efficiency and Speed Modern FIBC bag baffle sewing machines are designed for high-speed operation. They can significantly increase production rates, allowing manufacturers to meet the growing demand for FIBC bags without compromising quality.

2. Precision The importance of accurate stitching cannot be overstated. Poor seams can lead to product spills, resulting in costly waste and reduced safety. Advanced baffle sewing machines use computerized systems to ensure precise alignment and consistent stitching patterns.

3. Versatility These machines are often versatile enough to handle various sizes and configurations of FIBC bags, making them suitable for different applications. Manufacturers can streamline production and reduce downtime by not needing multiple machines.

4. Durability FIBC bags must withstand heavy loads and rough handling. Machines built for sewing baffles are constructed from robust materials and components designed for longevity, minimizing the need for frequent repairs.

Technological Advances in Baffle Sewing Machines

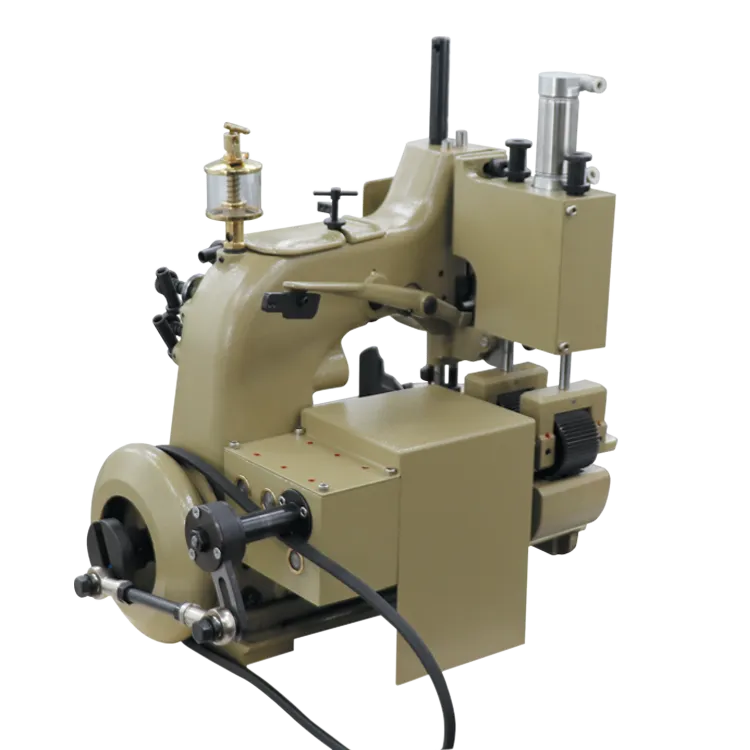

fibc bag baffle sewing machine

The design and functionality of FIBC bag baffle sewing machines have evolved significantly over the years. Key advancements include

- Automation Many modern machines incorporate automation features, such as automatic thread cutting and fabric feeding systems, which reduce labor costs and human error.

- Smart Technology Integrating smart technology allows for real-time monitoring of machine performance, automated diagnostics, and predictive maintenance, ensuring optimal operation and reducing downtime.

- Enhanced User Interfaces Contemporary machines often feature user-friendly interfaces that allow operators to easily program settings, monitor production, and adjust parameters on the fly.

Benefits to Manufacturers

Investing in advanced FIBC bag baffle sewing machines yields several benefits for manufacturers

- Cost Savings By improving efficiency and reducing waste, manufacturers can see significant cost savings in production.

- Quality Assurance With precise sewing capabilities, manufacturers can guarantee the quality and integrity of their bags, leading to increased customer satisfaction and loyalty.

- Scalability As the demand for FIBC bags continues to rise, manufacturers equipped with efficient sewing machines can scale their operations quickly to meet market needs.

Conclusion

FIBC bag baffle sewing machines are at the forefront of innovation in the bulk packaging industry. Their ability to enhance efficiency, precision, and versatility is vital to meeting the increasing demands of various industries. As technology continues to advance, these machines will undoubtedly continue to play a crucial role in the manufacturing landscape of FIBC bags. With their contributions to productivity and quality, baffle sewing machines are essential tools for any manufacturer looking to thrive in today's competitive market. Investing in these machines not only represents a commitment to efficiency but also a step towards embracing the future of packaging technology.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025