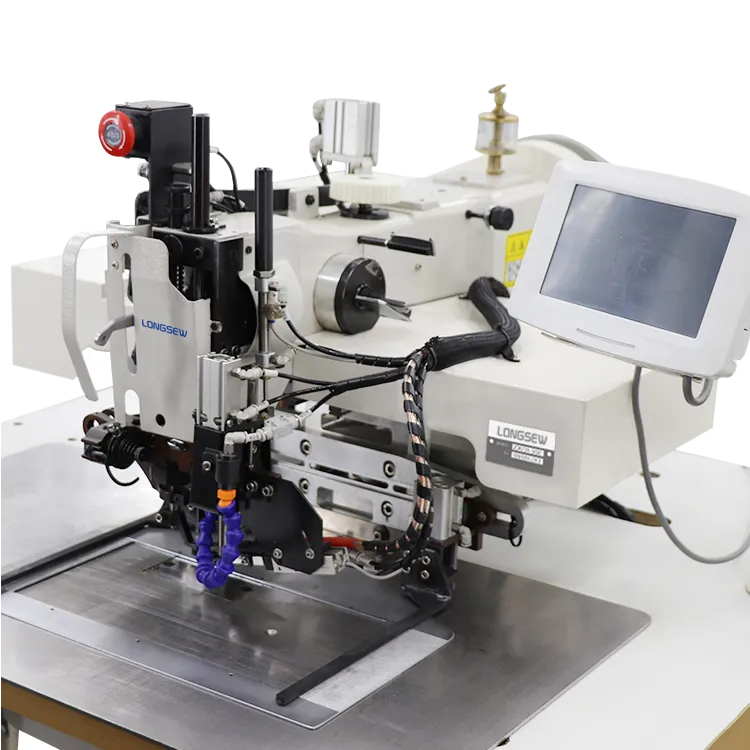

fibc bag auto sewing machine

The Advancement of FIBC Bag Auto Sewing Machines

In the world of industrial packaging, Flexible Intermediate Bulk Containers (FIBC), also known as bulk bags, play a pivotal role due to their ability to hold large quantities of material. From agriculture to pharmaceuticals, FIBC bags are widely used for transporting everything from grains to chemicals. As the demand for FIBC bags continues to rise, so does the need for efficient manufacturing processes. This is where FIBC bag auto sewing machines come into play, revolutionizing how these essential bags are produced.

Understanding FIBC Bags

FIBC bags are made from woven polyethylene or polypropylene fabric, which ensures strength and durability. Their design allows for easy handling and storage, making them ideal for bulk transport. However, the efficiency and quality of FIBC bags largely depend on how well they are sewn. Traditionally, sewing these bags required manual labor, which was not only time-consuming but also prone to errors. The introduction of automated sewing machines has transformed this aspect of production.

The Role of Auto Sewing Machines

Auto sewing machines are designed specifically for high-volume production of FIBC bags. These machines streamline the sewing process, ensuring that bags are securely constructed while maintaining high speed and precision. The key features of modern auto sewing machines include automatic threading, tension control, and programmable stitching patterns. This not only enhances speed—reducing production time considerably—but also ensures a consistent quality that is hard to achieve with manual sewing.

Benefits of Using Auto Sewing Machines

1. Increased Productivity Auto sewing machines can sew multiple bags per minute, vastly improving production rates. This is particularly important for businesses that need to meet high demand. The ability to operate continuously without fatigue ensures that companies can maintain a steady output.

fibc bag auto sewing machine

2. Cost Efficiency While the initial investment in auto sewing machines may be significant, the long-term savings are apparent. Businesses can reduce labor costs, minimize material waste due to imperfect sewing, and decrease the time to market for their products.

3. Enhanced Quality Control With automated systems in place, the consistency of each bag sewn is greatly improved. Automated machines are equipped with sensors and control systems that ensure each stitch is perfect, preventing quality issues that can arise from human error.

4. Versatility Modern auto sewing machines can handle various types of FIBC bag designs and sizes without the need for extensive adjustment. This flexibility allows manufacturers to respond quickly to market changes or customer specifications.

5. Safety Improvements Reducing the reliance on manual labor not only minimizes the risk of workplace injuries but also allows workers to focus on more complex tasks that require human oversight.

The Future of FIBC Bag Production

The landscape of FIBC bag production is rapidly evolving due to technological advancements. As industries continue to seek ways to optimize their operations, the demand for sophisticated sewing machines is set to rise. Innovations such as IoT integration, where machines can be connected to a network for real-time monitoring and analytics, are already on the horizon. This level of connectivity can lead to predictive maintenance, allowing for machines to be serviced before breakdowns occur—further streamlining production processes.

In conclusion, the advent of FIBC bag auto sewing machines represents a significant leap forward in the manufacturing sector. These machines not only enhance productivity and efficiency but also ensure high-quality output that meets the rigorous demands of various industries. As technology continues to advance, it is likely that we will see even more improvements in automated manufacturing processes, further solidifying the role of FIBC bags in logistics and supply chain management. The future of FIBC production is bright, and businesses that invest in these advanced solutions are sure to reap the benefits.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025